Why Raised Patio Construction is the Smart Choice for Your Woburn Backyard

Raised patio construction transforms sloped or uneven yards into level, usable outdoor living spaces that add both function and value to your property. Here’s what you need to know:

Essential Steps for Raised Patio Construction:

- Plan & Design – Measure slope, check codes for railings (required >24″ height)

- Excavate – Dig trench 24″ wide by 6″ deep plus 1″ per foot of wall height

- Build Foundation – Compact gravel base in 2-3″ lifts with plate compactor

- Install Retaining Wall – Level first course, stack blocks with proper offset

- Backfill & Compact – Use ¾” clear stone in 6″ layers behind wall

- Install Surface – Screed bedding material, lay pavers with 1% slope for drainage

Unlike ground-level patios that require extensive excavation, raised patios use retaining walls to create level surfaces above grade. This approach works perfectly for Woburn’s varied terrain and eliminates the messy space underneath traditional decks.

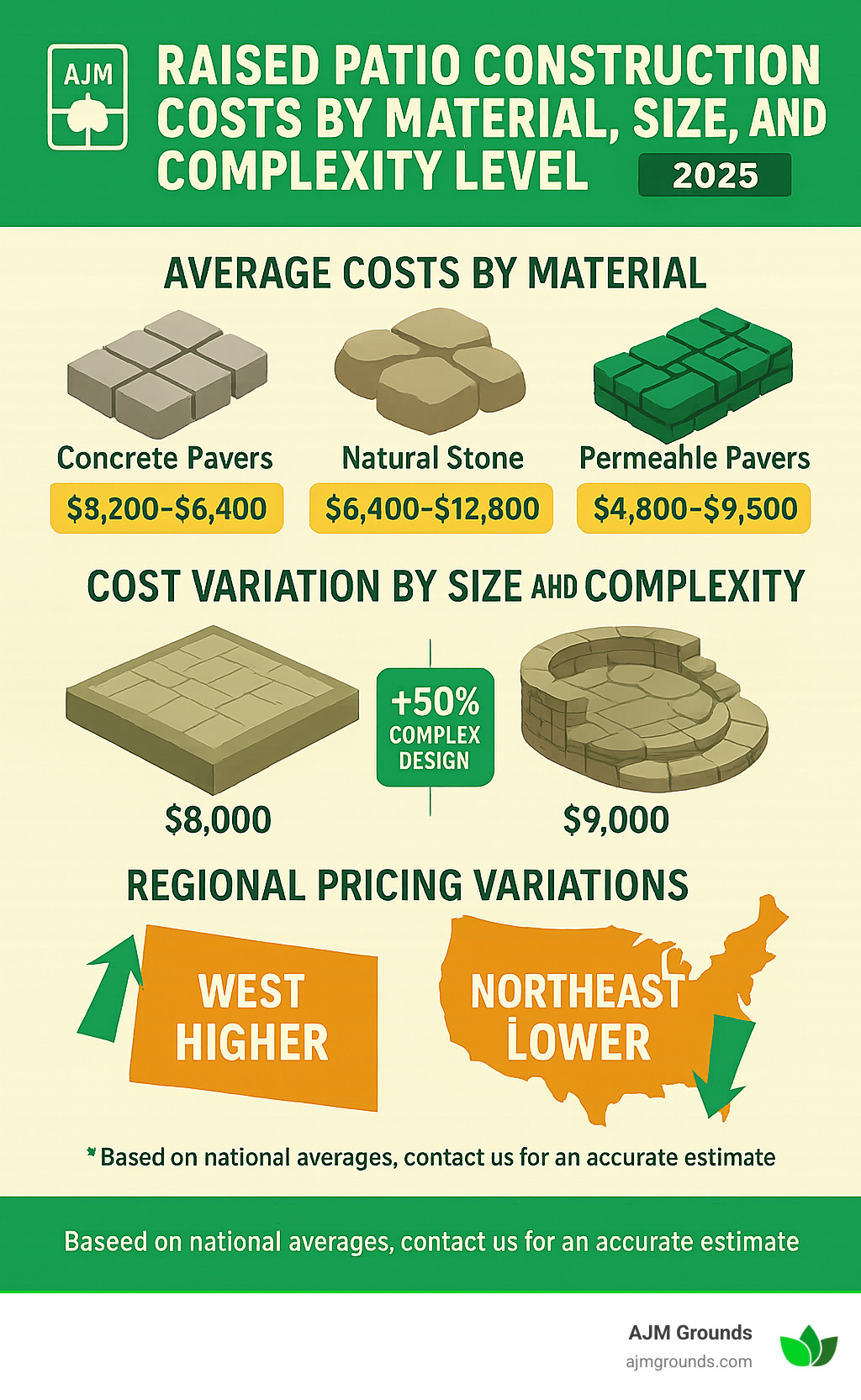

Cost ranges from $10-$85 per square foot based on internet averages, with materials like concrete pavers on the lower end and natural stone commanding premium prices. Walls over 36 inches typically require professional engineering and permits.

As John Caplis, owner of AJM Grounds LLC, I’ve helped dozens of Woburn homeowners steer the complexities of raised patio construction from initial design through final installation. My team specializes in creating durable, code-compliant outdoor spaces that improve both property value and daily living.

Find more about Raised patio construction:

Raised Patio Basics: What Sets It Apart

Picture this: you’re looking at your sloped backyard, imagining a perfect spot for morning coffee and evening barbecues. That’s where raised patio construction comes in – it’s like building a level platform above the natural grade using retaining walls for support.

The fundamental difference is all about working with your landscape instead of against it. Ground-level patios require you to excavate the entire area and work with existing slopes. Raised patios take a different approach – they use retaining walls to create a level surface above the original ground, which is perfect for Woburn’s rolling terrain.

Unlike sunken patios that are carved into hillsides for wind protection and privacy, raised patios lift you up above the landscape. This gives you better views and naturally better drainage – gravity becomes your friend instead of your enemy.

And here’s a bonus that many homeowners don’t consider: raised patios eliminate the messy under-deck storage area that becomes a magnet for pests and clutter.

| Feature | Raised Patio | Ground-Level Patio |

|---|---|---|

| Site Requirements | Works on slopes | Requires level ground |

| Excavation | Trench only for wall | Full area excavation |

| Drainage | Excellent (gravity-fed) | Requires careful grading |

| Views | Improved elevation | Ground level |

| Maintenance | Low (no under-deck area) | Moderate |

| Cost | $10-85/sq ft* | $8-50/sq ft* |

*Based on internet averages, not AJM Grounds pricing

Key Benefits of a Raised Patio

Better views and privacy top the list for most homeowners. When you’re lifted even just a few feet, you suddenly have sightlines over your landscaping and neighboring properties. In areas like Lexington and Winchester where lot elevations vary dramatically, this advantage becomes incredibly valuable.

Improved accessibility might surprise you as a benefit. Instead of navigating a long, steep staircase down a sloped yard, you step onto a level platform that connects smoothly to your home’s interior floor level.

Superior drainage happens naturally with elevation. Water flows away from your raised surface instead of pooling on it, which reduces ice formation during our harsh Massachusetts winters.

Extended living space transforms unusable sloped areas into functional outdoor rooms. We’ve helped homeowners gain hundreds of square feet of usable space by building up instead of cutting down.

Common Mistakes to Avoid in Raised Patio Construction

Poor base compaction ranks as the most expensive mistake in raised patio construction. Each lift of base material needs compacting with a plate compactor making at least two passes. Skip this step, and you’ll face settling and costly repairs within 2-3 years.

Missing or inadequate drainage behind the retaining wall will eventually compromise your entire project. Every raised patio needs perforated pipe with minimum 1/8″ per foot slope to daylight.

Siding contact creates a pathway for moisture and termites. Never allow fill material or pavers to touch wood siding. Maintain at least 6 inches clearance between any wood and final grade.

Undersized footings cause many DIY attempts to fail. The base trench must be 24 inches wide by 6 inches deep, plus 1 inch deeper for each foot of wall height.

Reusing excavated soil as fill seems economical but creates long-term problems. Native soil, especially the clay common in our area, doesn’t compact reliably. Clean crushed stone costs more upfront but prevents settlement issues down the road.

Planning & Design Essentials for Raised Patio Construction

Raised patio construction success depends on getting the planning phase right. I’ve seen too many weekend warriors jump straight into digging, only to hit a gas line or find their “level” patio actually slopes toward the house. That’s why we start every project with a proper site survey.

The site survey reveals everything that matters: existing slopes, utility locations, and drainage patterns. We mark all underground utilities through Dig Safe and measure the natural grade to determine how much elevation we need to gain. This is where the 1% slope rule becomes critical – your finished patio must slope at least 1/8 inch per foot away from your home for proper drainage.

Building codes add another layer of complexity. Railings become mandatory when your patio sits more than 24 inches above grade. If you’re planning walls over 36 inches, you’ll need a structural engineer’s stamp on your plans.

Raised patio construction costs vary widely based on materials and complexity. Internet averages range from $10-85 per square foot, with basic concrete paver installations at the lower end and premium natural stone projects reaching the upper range. These are general market averages, not AJM Grounds pricing.

Multi-level designs offer an neat solution for steep slopes. Instead of building one tall wall that requires railings, we often create stepped terraces that keep individual sections below code thresholds while maximizing usable space.

For design inspiration and ideas that work in our local climate, check out our Hardscape Patio Designs portfolio.

Soil & Drainage Assessment

Your soil type determines everything about your construction approach. The clay soils common throughout Woburn and surrounding areas present unique challenges. Clay holds water like a sponge, which creates pressure behind retaining walls and reduces bearing capacity for heavy loads.

Chemical amendment with granular lime solves this problem. Apply 50 pounds of lime per 100 square feet of clay subgrade to release trapped water and improve stability.

The drainage system starts during excavation. Perforated pipe must be installed at the back of your retaining wall trench, sloping at least 1/8 inch per foot to a daylight outlet. Never connect this drain to your foundation system – it needs its own independent outlet.

We wrap the drainage pipe in geotextile fabric and surround it with ASTM #57 clean stone. This prevents fine particles from clogging the pipe while allowing water to flow freely. For technical details on proper compaction techniques, this Scientific research on compaction best-practices provides excellent guidance.

Layout, Permits & Safety Codes

Accurate layout prevents costly mistakes. We use string lines and the 3-4-5 triangle method to establish perfectly square corners. The string lines also serve as our finished grade reference.

Engineering requirements kick in at 36 inches of wall height. At this point, you’ll need stamped plans from a qualified civil engineer and building permits. Even shorter walls may require permits depending on local codes. It’s always better to check with your local building department before starting construction.

Safety equipment isn’t optional. OSHA requires hard hats, safety glasses, gloves, and respiratory protection when cutting blocks or pavers. We also recommend steel-toed boots and high-visibility clothing on active job sites.

Railing styles range from simple aluminum systems to decorative wrought iron or tempered glass panels. Glass railings avoid the “trapped feeling” of solid barriers while meeting safety codes.

Step-by-Step Build Guide

Now comes the exciting part – turning your plans into reality. Raised patio construction follows a specific sequence that can’t be rushed or rearranged. Each step builds the foundation for the next, and skipping ahead almost always means redoing work later.

Before breaking ground, complete this essential checklist: Call 811 for utility locates at least 72 hours ahead. Obtain any required permits. Stage all materials where they won’t interfere with construction. Check the weather forecast – you need at least 48 hours without rain.

The construction sequence follows this order: site preparation and excavation, base preparation and compaction, first course installation and leveling, wall construction with proper backfill, drainage system installation, paver base preparation, and finally paver installation and finishing touches.

Site Preparation & Excavation

Start by marking your layout with white spray paint – it’s the only color that won’t be confused with utility markings. Those bright pink and blue lines the utility companies spray are there for your safety, so respect them completely.

Excavate the retaining wall trench to exact dimensions: 24 inches wide by 6 inches deep plus 1 inch for each foot of planned wall height. For a 3-foot wall, you’re digging 9 inches total depth. This isn’t a suggestion – it’s the minimum requirement for structural integrity.

Precision matters more than speed during excavation. Maintain 1/4 inch tolerance on your trench dimensions. A sloppy trench means a wobbly wall, and there’s no fixing that later without starting over.

Install geotextile fabric in the trench bottom and sides, overlapping pieces by 12 inches. This fabric prevents soil from migrating into your clean stone while allowing water to drain through.

Compact the trench bottom with a plate compactor making at least 2 passes. The subgrade must be uniformly firm before placing any base material.

For professional installation services, learn more about our Hardscape Installation Service.

Building a Retaining Wall that Lasts

The first course determines everything that follows – get it wrong and every subsequent course will be wrong too. Set blocks perfectly level using a 4-foot level and adjust with sand as needed. Check alignment with string lines and verify the course is straight before moving on.

Fill hollow cores and the area 12 inches behind blocks with wall rock (ASTM #57 clean stone). This isn’t optional filler – it’s the structural foundation for your entire wall. Compact this material thoroughly with your plate compactor.

Install biaxial geogrid every 8 inches of wall height for multidirectional strength. Think of this grid as the rebar of your retaining wall system. It extends into the backfill area and locks everything together into one solid mass.

Each subsequent course should be offset by half the block length, creating a running bond pattern like brickwork. This pattern distributes loads evenly and prevents vertical cracks from forming.

Apply polyurethane adhesive to cap blocks in beads perpendicular to the block length. This orientation allows drainage while securing the caps against displacement.

Drainage & Backfill Techniques

Backfill with 3/4″ clear stone gravel in 6-inch lifts, compacting each layer before adding more material. This creates a stable, well-draining mass that won’t settle over time. Never use native soil or recycled concrete as backfill – it will cause problems later.

Install the drainage pipe with minimum 1/8″ per foot slope to daylight. In Massachusetts, this often means connecting to a drainage swale or existing storm system. Never connect to foundation drains or septic systems.

Shingle geotextile fabric on excavation sides to prevent soil migration into your clean stone backfill. Overlap pieces by 12 inches minimum and secure with landscape pins.

Installing Pavers & Finishing Touches

Screed a 1-inch bedding layer using washed concrete sand or specialized paver sand. The key word here is “washed” – sand with clay or silt content will cause problems with drainage and frost heave.

Lay pavers in your chosen pattern, working from straight edges toward curves or irregular areas. Use a chalk line to maintain straight rows and check square frequently with the 3-4-5 triangle method.

Compact pavers into the bedding with a plate compactor equipped with a rubber pad. Make multiple passes until no further settlement occurs.

Fill joints with polymeric sand, which hardens when activated with water. This prevents erosion and weed growth while allowing slight movement during freeze-thaw cycles. Follow the manufacturer’s instructions exactly.

Consider integrated seating walls using matching block materials. These provide function while eliminating the need for separate furniture that might blow around in storms.

Install lighting conduits during construction rather than retrofitting later. Low-voltage LED systems highlight steps and edges for safety while creating ambiance for evening entertaining.

For comprehensive patio services, visit our Patio Installation page.

Materials, Tools & Cost Breakdown

Getting your materials list right makes the difference between a smooth build and multiple trips to the supply yard. After building dozens of raised patios throughout Woburn and surrounding towns, I’ve learned that having everything on-site before you start saves both time and frustration.

Retaining blocks form the backbone of your project. Segmental concrete blocks stack easily and provide proven strength. You’ll need capstones for the finished top course and polyurethane adhesive to secure them. Don’t forget biaxial geogrid – this reinforcement fabric distributes loads in multiple directions.

The foundation starts with ASTM #57 clean stone, which provides excellent drainage and compaction characteristics. Geotextile fabric keeps soil from migrating into your clean stone. Perforated drainage pipe (minimum 4-inch diameter) carries water away from the wall.

For the patio surface, you’ll need bedding sand or specialized aggregate, plus polymeric jointing sand that hardens when wet. Edge restraints in plastic or aluminum keep pavers from shifting over time.

Equipment makes the job possible. A plate compactor delivering at least 5,000 pounds of force is essential – no shortcuts here. You’ll also need a 4-foot level, string lines for layout, and a circular saw with diamond blade for cutting blocks and pavers. Safety gear including hard hats, safety glasses, and steel-toed boots isn’t optional.

Cost ranges vary dramatically based on materials and complexity. Basic concrete paver projects start around $10-30 per square foot, while mid-range natural stone installations run $25-50 per square foot. Premium materials with complex designs can reach $50-85 per square foot. Railing systems add $15-75 per linear foot, and engineering fees for tall walls range $500-2,000. These are average costs based on internet data, not actual AJM Grounds pricing. Contact us for accurate project estimates.

Choosing the Right Surface Material

Concrete pavers offer the sweet spot of durability, cost, and appearance for most raised patio construction projects. They’re manufactured to precise tolerances, resist our harsh New England freeze-thaw cycles, and come in dozens of colors and textures. Order 10% extra for square patios and 20% for curved designs to account for cutting waste and future repairs.

Natural stone brings best beauty but demands more skill and budget. Bluestone, granite, and limestone are popular choices that complement New England architecture. These materials cost 2-3 times more than concrete pavers but can last centuries with proper installation.

Permeable pavers solve drainage challenges by allowing water to infiltrate through the surface. They work particularly well over open-graded bases in areas with good soil drainage.

Color coordination with your home’s exterior creates visual harmony that boosts curb appeal. Modern homes look sharp with smooth pavers in black, white, or gray. Traditional homes pair better with textured surfaces in earth tones.

The beauty of paver systems is their repairability. Individual units can be lifted and replaced if damaged, something impossible with poured concrete.

For specialized installations custom to your specific needs, explore our Custom Patio Installations services.

Building for Durability, Safety & Low Maintenance

Massachusetts weather demands construction that withstands freeze-thaw cycles. Use flexible, dry-stack retaining wall systems rather than mortared stone, which cracks when soil expands and contracts.

Maintain a ½-inch gap between the patio wall and your home’s foundation. This prevents pressure transfer during soil movement and allows for thermal expansion. Fill this gap with closed-cell foam backer rod and seal with polyurethane caulk.

Pest barriers start with proper clearance. Keep all wood siding at least 6 inches above final grade and never allow soil or mulch to contact wood surfaces. Even with barriers, moisture and termites will eventually find their way through small gaps.

Annual inspections catch problems early. Check for settling, joint separation, or drainage issues each spring. Clean polymeric sand joints and reseal as needed to prevent weed growth.

Sealing options depend on surface material. Concrete pavers benefit from penetrating sealers applied every 3-5 years. Natural stone may require different products depending on porosity and mineral content.

For technical information about retaining wall stability, consult this Scientific research on retaining wall stability.

Frequently Asked Questions about Raised Patio Construction

When planning your raised patio construction project, homeowners in Woburn and surrounding areas ask similar questions. Here are the most common concerns we address during our initial consultations.

How deep should the base and footing be?

The foundation depth depends on your wall height, but there’s a simple formula that works for most residential projects. Start with a base trench that’s 24 inches wide by 6 inches deep, then add 1 inch for each foot of wall height. So if you’re building a 3-foot retaining wall, you’ll need to excavate 9 inches total depth.

Here’s why this matters: the first course of blocks must be buried at least 6 inches below your finished grade for stability. Without proper burial depth, frost heave will shift your wall during winter months – something we see frequently in Massachusetts.

After excavation, install 6 inches of compacted gravel base using ASTM #57 clean stone. This provides adequate bearing capacity for most residential applications. However, if you’re dealing with clay soil or planning a wall over 4 feet tall, you may need to go deeper or consult a structural engineer.

Do I need a permit or engineer for my raised patio?

Permits depend on wall height and your local building codes. Most townships around Woburn require permits for walls over 3 feet tall, and engineering becomes mandatory at 36 inches in many areas. The good news? We handle permit applications for our clients, so you don’t need to steer the bureaucracy alone.

Even when permits aren’t required, engineering consultation adds real value for complex sites or tall walls. A structural engineer can specify reinforcement details and ensure your design meets current standards. This upfront investment prevents costly repairs later.

Here’s a practical tip: if you’re close to the height threshold, consider stepping your patio design with multiple shorter walls instead of one tall one. This approach often eliminates permit requirements while creating more interesting visual appeal.

What’s the best way to prevent water from pooling on a level patio?

You have two proven approaches: slope the patio surface or use permeable materials. The traditional method slopes your patio 1% away from structures – that’s just 1/8 inch drop per foot. Most people can’t even notice this subtle grade, but it effectively moves water toward landscape areas or drains.

Alternatively, install the patio completely level and use permeable jointing compound over an open-graded base. This allows surface water to infiltrate rather than run off, eliminating the need for surface slope in many situations. This approach works particularly well with our clay soils that need help with drainage.

Both methods require proper subsurface drainage behind your retaining wall. Install perforated pipe sloped to daylight to handle groundwater and prevent pressure buildup. Without this crucial step, even the best surface drainage won’t prevent long-term problems.

The key is matching your drainage strategy to your specific site conditions. During our site assessment, we evaluate soil type, existing drainage patterns, and proximity to structures to recommend the best approach for your property.

Conclusion

Raised patio construction transforms challenging sloped yards into functional outdoor living spaces that improve both daily life and property value. The key lies in proper planning, quality materials, and meticulous installation techniques that ensure decades of trouble-free performance.

When you choose the right approach, your raised patio becomes more than just a place to put outdoor furniture. It becomes the heart of your outdoor living space – a place where family gatherings happen naturally and where you actually want to spend time after a long day.

At AJM Grounds, we bring over a decade of experience to every raised patio construction project throughout Woburn, Bedford, Billerica, Burlington, Lexington, Reading, Stoneham, Wilmington, and Winchester. We’ve learned that the difference between a good patio and a great one comes down to the details most people never see – the compaction, the drainage, the precise leveling that prevents settling years down the road.

Our attention to detail and personalized service ensures your outdoor space exceeds expectations while meeting all safety and building codes. We take the time to understand how you plan to use your space, whether that’s hosting summer barbecues or creating a quiet morning coffee spot overlooking your garden.

From initial design consultation through final cleanup, we handle every aspect of your project with the professionalism and craftsmanship that has made us the trusted choice for discerning homeowners throughout the region. We’re not just building a patio – we’re creating the foundation for countless future memories.

Ready to transform your sloped yard into an outdoor showpiece? Contact AJM Grounds today for a custom consultation and detailed project proposal. Let us show you how raised patio construction can open up your property’s full potential and give you the outdoor living space you’ve always wanted.

Explore our complete range of services at Hardscaping Services and find why homeowners throughout the greater Boston area choose AJM Grounds for their most important outdoor projects.