Why Laying a Brick Path is a Smart Home Investment

Laying a brick path is one of the most rewarding DIY projects you can tackle to boost your home’s curb appeal and solve muddy walkway problems. Here’s what the process involves:

Quick Steps for Laying a Brick Path:

1. Plan & measure – Mark your route and calculate materials

2. Excavate – Dig 8-10 inches deep for proper foundation

3. Build base – Add 4-6 inches gravel + 1 inch sand

4. Lay bricks – Set in your chosen pattern with rubber mallet

5. Finish – Sweep polymeric sand into joints and compact

Whether you’re tired of muddy trails across your yard or want to create an neat entrance to your home, a brick path offers timeless appeal that works with any architectural style. The project typically takes 16-20 hours over a weekend and costs $100-$1,000+ in materials for a DIY installation.

A properly installed brick path can last decades with minimal maintenance. The key is getting the foundation right – that 8-10 inch excavation might seem excessive, but it’s what separates paths that last from those that heave and crack after the first New England winter.

I’m John Caplis, owner of AJM Grounds LLC, and I’ve been helping Woburn homeowners improve their outdoor spaces for years through professional landscaping and hardscaping services. My team has experience in laying a brick path installations, from simple garden walkways to elaborate patio connections that stand up to our harsh Massachusetts winters.

Find more about laying a brick path:

– installing a garden path

– dry laid flagstone walkway

– walkway contractors near me

Why Choose a Brick Path?

There’s something magical about walking on a brick path that connects you to centuries of craftsmanship. When you’re laying a brick path, you’re not just creating a walkway – you’re adding heritage charm that makes your home feel rooted in history.

Here’s what makes brick paths so special: they’re incredibly forgiving. Unlike concrete that can crack in dramatic zigzags, brick offers easy repair options. If one brick settles or chips, you simply pop it out and replace it. No jackhammering, no matching concrete colors – just swap in a new brick and you’re done.

The slip resistance of brick becomes your best friend during New England’s unpredictable weather. Those textured surfaces create natural traction that keeps you steady when autumn leaves get slippery or winter brings its icy surprises.

Permeable surfaces solve a real problem. Water doesn’t just sit on top of your brick path – it filters down between the joints, reducing puddles and preventing stubborn ice patches. This eco-friendly approach also helps manage stormwater runoff.

From a financial standpoint, a well-installed brick path delivers a solid property value boost. Potential buyers see quality hardscaping and immediately understand they’re looking at a home where details matter.

Reclaimed bricks add character for environmentally conscious homeowners. These weathered beauties bring instant character while keeping materials out of landfills. Plus, they often cost less than new bricks while delivering that authentic aged look.

The winter durability of brick paths really shines in our Massachusetts climate. While other materials expand, contract, and crack through freeze-thaw cycles, properly installed brick paths actually improve with age.

Benefits of Laying a Brick Path in New England Gardens

Our Massachusetts climate throws everything at outdoor surfaces – from summer thunderstorms to winter nor’easters – which makes the freeze-thaw resistance of brick paths particularly valuable. Individual bricks can handle ground movement that would create major cracks in solid concrete.

Four-season use means your investment works year-round. The surface stays usable when wooden walkways become slippery and metal surfaces turn treacherous.

The classic aesthetics of brick complement virtually every architectural style found in New England. Whether your home features colonial charm, Victorian details, or contemporary lines, brick paths provide that timeless foundation that ties everything together.

Planning & Design Essentials

The secret to laying a brick path that lasts decades starts with smart planning. Before you grab a shovel, spend time walking your intended route at different times of day and in various weather conditions.

Path width is where many DIYers make their first mistake. While a narrow 2-foot path might seem like it saves money, you’ll regret it later. A 3-4 foot width allows two people to walk side by side comfortably and gives you space for wheelbarrows and equipment.

Gentle curves create visual interest and feel more natural than rigid straight lines, but keep those curves reasonable. Sharp turns create headaches when cutting bricks. If your landscape demands curves, stick to a radius of at least 5 feet.

Proper drainage starts with getting your slope right – aim for ¼ inch of fall per foot of path length, always directing water away from your home’s foundation.

Before you dig even one shovel full of dirt, call 811 to have utilities marked. That free utility marking service can save you thousands in repair costs.

When planning your layout, consider using landscape fabric as a weed barrier and choose your edging material early – it affects your excavation width.

More info about Installing a Walkway

Pattern Comparison for Laying a Brick Path:

| Pattern | Difficulty | Cutting Required | Best For | Visual Impact |

|---|---|---|---|---|

| Running Bond | Easy | Minimal | Straight paths, beginners | Clean, classic |

| Herringbone | Moderate | Moderate | High-traffic areas | Dynamic, strong |

| Basket Weave | Easy | Minimal | Wide paths, patios | Traditional, formal |

Calculating Materials for Laying a Brick Path

Getting your material calculations right prevents frustrating mid-project runs to the supply yard.

Start with your brick count by measuring path length times width, then multiply by your pattern’s coverage rate. Basket weave patterns typically use about 8 bricks per square foot, while herringbone and running bond patterns vary based on your specific brick size.

Here’s the golden rule: add 10% waste factor to whatever number you calculate. This covers cutting mistakes, breakage during installation, and future repairs.

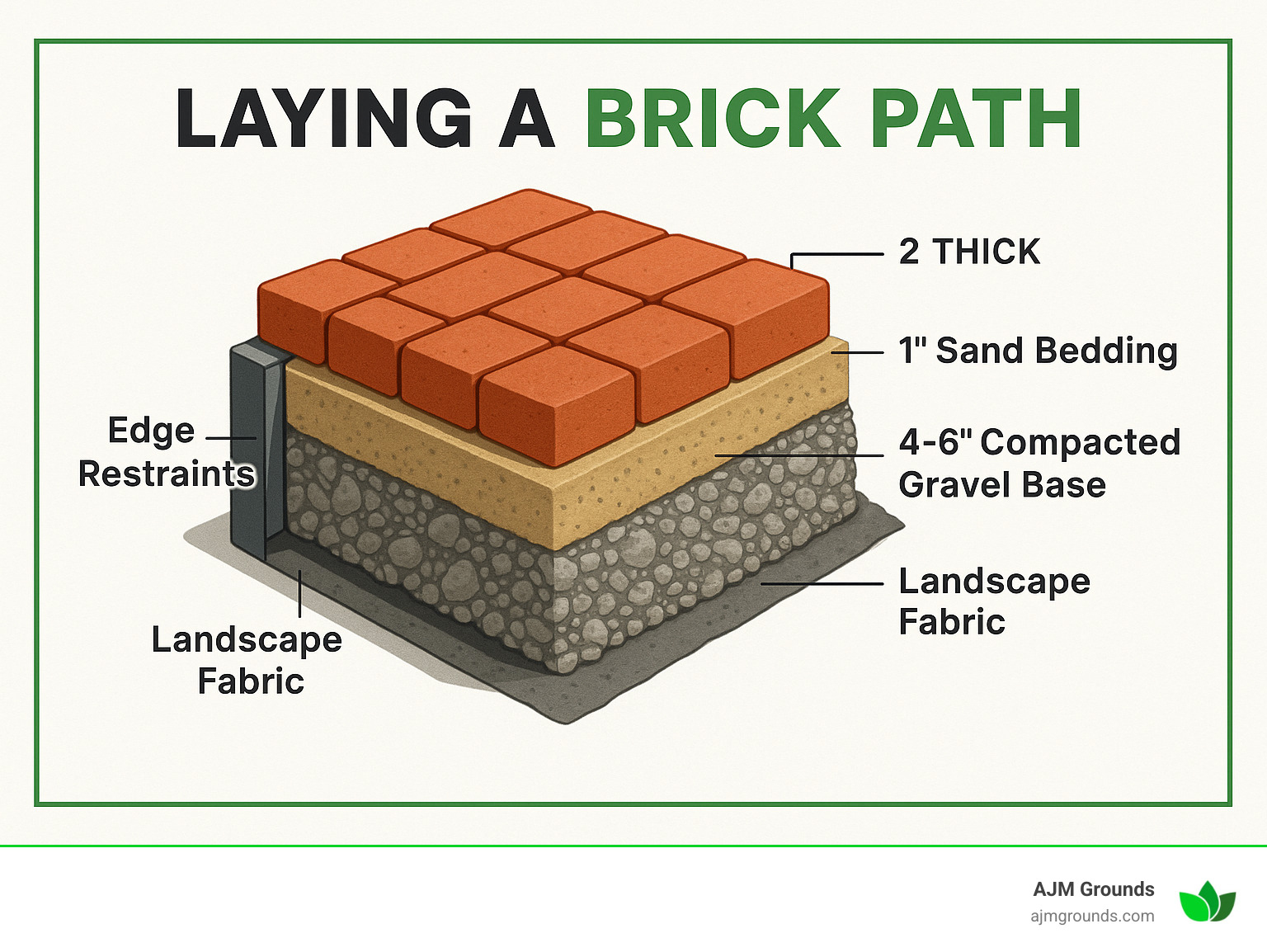

Your excavation depth follows a simple formula: brick thickness (usually 2 inches) plus sand layer (1 inch) plus gravel base (4-6 inches) equals 7-9 inches total. Most professionals excavate to 8-10 inches to ensure adequate base material.

Choosing Bricks & Pavers

The “ring test” is your secret weapon for choosing quality bricks. Simply knock two bricks together – clay pavers fired at high temperatures produce a clear, bell-like ring, while softer bricks make a dull thud.

Clay pavers offer superior durability and weather resistance compared to standard building bricks. They’re specifically manufactured for ground contact and our brutal freeze-thaw cycles.

Concrete pavers provide another excellent option, often at lower cost than clay. Modern concrete pavers come in colors and textures that closely mimic traditional brick.

Reclaimed bricks bring incredible character and environmental benefits, but they require careful selection. Test each brick for soundness using the ring test and avoid any with obvious cracks.

For color matching, buy all your bricks from the same lot when possible to avoid noticeable color differences.

Tools & Materials Checklist

The right tools make all the difference when laying a brick path. I’ve watched countless DIY enthusiasts turn what should be a satisfying weekend project into a weeks-long ordeal simply because they tried to make do with inadequate equipment.

Your pointed spade becomes your best friend during excavation – it cuts clean lines through soil and roots that a standard shovel just can’t match. Choose a wheelbarrow that matches your physical capabilities rather than going for the largest one available.

A hand tamper handles base compaction in tight spaces, but here’s where I recommend splurging on a rental: a plate compactor transforms this job from back-breaking labor into efficient work. Most tool rental centers around Woburn stock these machines, and the $40-60 daily rental cost pays for itself in time savings.

The PVC screed pipes (1-inch diameter) paired with a straight 2×4 board create a leveling system that separates amateur work from professional-looking results. This simple setup ensures your sand base stays perfectly level.

Safety gear often gets skipped in the excitement to start building, but cutting bricks creates serious dust and noise hazards. A quality dust mask, safety glasses, and ear protection aren’t optional when you fire up that masonry saw or angle grinder.

Don’t forget the polymeric sand for finishing – this isn’t regular sand, and the difference shows in how well your joints hold up over time.

More info about Hardscaping Services

Must-Have Tools for Laying a Brick Path

Your tape measure needs to reach at least 25 feet to handle most residential paths without constant repositioning. A 4-foot spirit level keeps your base preparation true, while string lines stretched between stakes provide the visual guides that keep everything straight during both excavation and brick laying.

The rubber mallet deserves special attention – never use a steel hammer directly on bricks. The rubber mallet provides exactly the right force to seat bricks properly without damage.

Optional Pro Tools to Speed the Job

A vibratory compactor creates professional-quality base preparation in a fraction of the time hand tamping requires. For paths longer than 100 feet, this rental investment pays dividends.

Wet tile saws produce cleaner cuts than angle grinders, especially important for those visible edge pieces. The water cooling eliminates dust clouds, though the setup time makes them most valuable when you’re facing numerous precise cuts.

Step-by-Step: Laying a Brick Path the Right Way

The foundation of any successful brick path lies in proper excavation and base preparation. We always tell homeowners in Stoneham and Wilmington that the work you can’t see determines how long your path will last.

Start with an excavation depth of 8-10 inches below your desired finished grade. This provides room for 4-6 inches of compacted gravel base, 1 inch of leveling sand, and 2-inch thick bricks. Compact the soil at the bottom of your trench using a hand tamper or plate compactor.

Weed barrier fabric provides long-term benefits that justify the modest additional cost. Heavy-duty landscape fabric prevents sand from sifting down into the gravel base while blocking weeds.

The gravel base requires two-stage installation for optimal results. Spread half your gravel (2-3 inches), compact thoroughly, then add the remaining gravel and compact again.

Sand screeding using PVC pipes ensures consistent thickness across the entire path width. Set the pipes at the correct height, spread sand to slightly above the pipe level, then drag a straight board across the pipes to create a perfectly level surface.

How to lay the base for a brick path

Preparing the Ground for Laying a Brick Path

Mark your path outline using garden hoses for curves or stakes and string for straight sections. Spray paint provides a permanent reference that won’t move during excavation.

Call 811 at least 48 hours before digging. Utility location is free and required by law in Massachusetts.

Dig your trench with straight, vertical sides using a pointed spade. Save the topsoil for reuse in garden beds – good soil is valuable and shouldn’t be wasted.

Building a Stable Base Layer

Crusher-run gravel provides the ideal base material for New England conditions. This mixture of graded stone and stone dust compacts tightly while maintaining drainage capabilities.

Two-stage compaction creates superior results. The first pass seats the larger stones, while the second pass locks everything together. Use overlapping passes with your compactor.

Check your slope frequently during base preparation. A 4-foot level with a ¼-inch shim under one end provides a simple gauge for the recommended ¼-inch per foot drainage slope.

Setting Bricks in Your Chosen Pattern

Running-bond patterns work well for beginners and straight paths. Start at one end and work systematically toward the other, maintaining consistent joint spacing.

Herringbone patterns provide superior interlock strength, making them ideal for areas that will see heavy use. The 45-degree angle creates more cutting work but results in a stronger surface.

Basket-weave patterns offer traditional appeal with relatively simple installation. Groups of two or three bricks laid perpendicular to adjacent groups create the classic basket appearance.

Soldier-course borders provide clean edges and help contain the field bricks. Set these edge bricks first, using them as guides for the interior pattern.

Cutting Bricks for Curves & Edges

A brick chisel and hammer provide the traditional method for splitting bricks. Score the brick on all four sides, then strike firmly with the chisel positioned on your score line.

Angle grinders with masonry blades produce cleaner, more precise cuts but generate significant dust. Always wear proper respiratory protection and work in well-ventilated areas.

Mark each cut individually rather than trying to batch-cut multiple pieces. Test-fit each piece before making final cuts.

Finishing Touches & Long-Term Care

The final steps in laying a brick path transform your hard work into a professional-looking walkway that will serve your family for decades.

Polymeric sand represents one of the biggest advances in hardscaping materials. Unlike regular sand that washes away with the first heavy rain, polymeric sand contains binding agents that activate when moistened. Sweep this specialized material thoroughly into all joints, making sure to fill them completely. Then mist the entire surface lightly – not soaking wet, just enough moisture to activate the binding process.

The change happens over the next 24 hours as the polymeric sand hardens into a semi-permanent joint material that resists washout and creates an inhospitable environment for weeds.

Sealing your brick path remains optional for most New England applications. Quality bricks and proper installation provide excellent durability without additional treatments. However, sealing can improve stain resistance for lighter-colored bricks, though sealed surfaces typically need resealing every 3-5 years.

Weed control starts with the foundation work you’ve already completed. That landscape fabric beneath your base and the polymeric sand in your joints create multiple barriers against unwanted plant growth.

Winter brings unique challenges to Massachusetts walkways, but properly installed brick paths handle frost-heave better than almost any other material. If a few bricks do heave after a harsh winter, the fix is straightforward – lift the affected bricks, adjust the sand base underneath, and tap them back into place.

More info about Walkway Installers

Common Mistakes to Avoid When Laying a Brick Path

Insufficient excavation depth tops the list of DIY failures. The temptation to save time by reducing that 8-10 inch excavation to just 6 inches creates paths that settle and crack within the first year.

Poor compaction ranks as the second most common error. The gravel base needs serious compression to lock together properly. A few hours with a rented plate compactor will save you from rebuilding the entire path.

Skipping edge restraints might seem minor, but it’s what keeps your beautiful pattern from slowly spreading apart over time. Without proper edging, the outer bricks gradually shift outward, creating gaps.

Wrong brick selection causes heartbreak when beautiful new paths start crumbling after their first winter. Always verify that your bricks are rated for paving applications.

Maintenance Schedule & Quick Fixes

A well-built brick path requires surprisingly little ongoing maintenance. Annual joint top-up should become part of your spring routine. Even the best polymeric sand gradually wears away in high-traffic areas.

Pressure washing removes winter grime beautifully, but use restraint with the pressure setting. Too much force can blast out your joint sand. Often, a garden hose provides plenty of cleaning power.

Reset loose bricks immediately when you notice them – this five-minute fix prevents adjacent bricks from shifting. Lift the loose brick, add sand to the base as needed, and tap it back into level.

The beauty of brick paths lies in their repairability. Unlike concrete that requires jackhammering, brick paths let you fix issues one piece at a time.

Budget, Timeline & DIY vs Pro Considerations

Let’s talk numbers – because nobody likes budget surprises halfway through a project. Laying a brick path yourself typically costs between $100-$1,000+ in materials, based on internet research. These are average costs and not actual pricing for AJM Grounds services. The wide range depends on your path size, brick choice, and whether you go for basic clay pavers or premium reclaimed materials.

Professional installation tells a different story entirely. Average costs run $15-$45 per square foot according to industry data, with high-end installations reaching $135+ per square foot for complex designs or premium materials. That means a 200 square foot path could range from $3,000 to $27,000 professionally installed.

The 16-20 working hours that professionals quote assumes you know what you’re doing and have the right tools. First-time installers should realistically double that estimate. I always recommend breaking the project into manageable weekend chunks: excavation and base prep one weekend, brick laying the next.

Tool rental adds $100-300 to most projects, but that plate compactor rental costs less than the materials for just a few square yards of path. When you consider that poor compaction is the #1 reason DIY paths fail, the rental fee becomes the best money you’ll spend.

Reclaimed bricks offer significant savings but come with hidden time costs. You’ll spend hours sorting through bricks, cleaning old mortar, and dealing with irregular sizes. If you love the character of old bricks, it’s worth it. If you just want to get the path done, new pavers will save your sanity.

Several factors can push your costs higher: path size and complexity, site accessibility if you need to hand-carry materials, soil conditions requiring extra excavation, disposal costs for removed dirt, and drainage improvements.

Adapting the Process for Slopes & Curves

Slopes change everything about laying a brick path. Anything steeper than 8-10% needs stepped construction to prevent your path from becoming a brick waterfall after heavy rain. Gentler slopes can work with ramped construction, but you’ll need extra attention to drainage.

Curves look graceful but require more planning than straight paths. Flexible edging materials like plastic landscape edging bend smoothly around gentle curves, while steel edging handles tighter turns. Order extra materials – curved paths always need more cutting than initial calculations suggest.

Extra compaction becomes critical at curve transitions and slope changes. These areas experience more stress and movement, so they need additional base material and more thorough compaction.

If your slope requires retaining walls or your curves are particularly complex, that’s when professional design and installation make the most sense.

Frequently Asked Questions about Laying a Brick Path

How wide and deep should my brick path be?

Path width makes a bigger difference than most homeowners realize. While you might think 2 feet saves money, 3 feet minimum creates a comfortable walking experience. 4 feet works even better – two people can walk side by side, and you’ll have room for wheelbarrows without stepping into garden beds.

The excavation depth of 8-10 inches isn’t excessive – it’s what separates paths that last from those that crack after one winter. Here’s how it breaks down: 4-6 inches of compacted gravel creates your foundation, 1 inch of leveling sand provides a smooth bed, and 2-inch thick bricks complete the surface.

This depth matters especially here in Massachusetts. Our freeze-thaw cycles destroy shallow installations, but proper depth allows the path to move slightly without cracking.

Can I use reclaimed bricks safely?

Reclaimed bricks bring wonderful character to any path, and they’re often available at significant savings. The key is knowing how to select quality pieces that will hold up to New England weather.

Try the “ring test” before buying – knock two bricks together and listen carefully. Well-fired, durable bricks produce a clear ring, almost like a bell. Soft or damaged bricks make a dull thud and should be avoided.

Avoid any bricks with obvious cracks or crumbling mortar still attached. Clean your selected bricks thoroughly and sort them by size before starting installation – reclaimed bricks often vary more than new ones.

The extra sorting time is worth it for the unique character and environmental benefits.

How do I prevent weeds between bricks?

Weed prevention starts during installation, not after weeds appear. Landscape fabric beneath your gravel base blocks weeds from growing up through the foundation, while polymeric sand in the joints creates a hardened surface that most weeds can’t penetrate.

Polymeric sand transforms when moistened – it hardens into a semi-permanent joint filling that resists washout and weed growth. Sweep it thoroughly into all joints, then mist lightly to activate the binding agents.

Annual maintenance prevents small problems from becoming big ones. Top up joint sand each spring and remove any weeds that do manage to sprout immediately.

The combination of proper base preparation and quality joint materials eliminates 95% of weed problems. The few that do appear are usually easy to pull by hand since they can’t establish deep root systems in the hardened sand.

Conclusion

There’s something deeply satisfying about laying a brick path that connects your home to the landscape around it. You’re not just creating a walkway – you’re building something that will welcome guests, guide family members safely through your garden, and add lasting value to your property for decades to come.

The beauty of brick lies in its durable charm that never feels outdated. While other materials come and go with design trends, brick paths maintain their appeal whether your home is a classic colonial or a modern contemporary. The natural variations in color and texture create visual interest that actually improves with age.

Custom design flexibility means your path can be as simple or elaborate as your vision demands. A straight running-bond pattern offers clean elegance, while a herringbone design creates dynamic visual movement.

Perhaps the biggest advantage is the low upkeep requirements once your path is properly installed. Unlike concrete that can develop unsightly cracks or wooden walkways that need regular staining, brick paths ask very little of you. An annual sweep of fresh sand into the joints and the occasional releveling of a settled brick – that’s about all the maintenance you’ll need.

Ready to build your perfect walkway? While this guide gives you everything needed for a successful DIY installation, we understand that some projects benefit from professional expertise. Complex curves, challenging slopes, or simply the desire to ensure everything is done right the first time are all good reasons to consider professional installation.

More info about Walkway Installation – AJM Grounds has helped countless homeowners in Woburn and surrounding communities transform their outdoor spaces with quality brick path installations. Our attention to detail and personalized approach means your vision becomes reality, built to last through everything New England weather can deliver.

Whether you roll up your sleeves for a weekend DIY project or partner with professionals, laying a brick path represents one of those rare home improvements that delivers both immediate satisfaction and long-term value. Every time you walk that path – whether it’s the first spring morning or a snowy winter evening – you’ll appreciate the decision to choose a material and method that stands the test of time.