What is a Gabion Wall and Why Should You Build One?

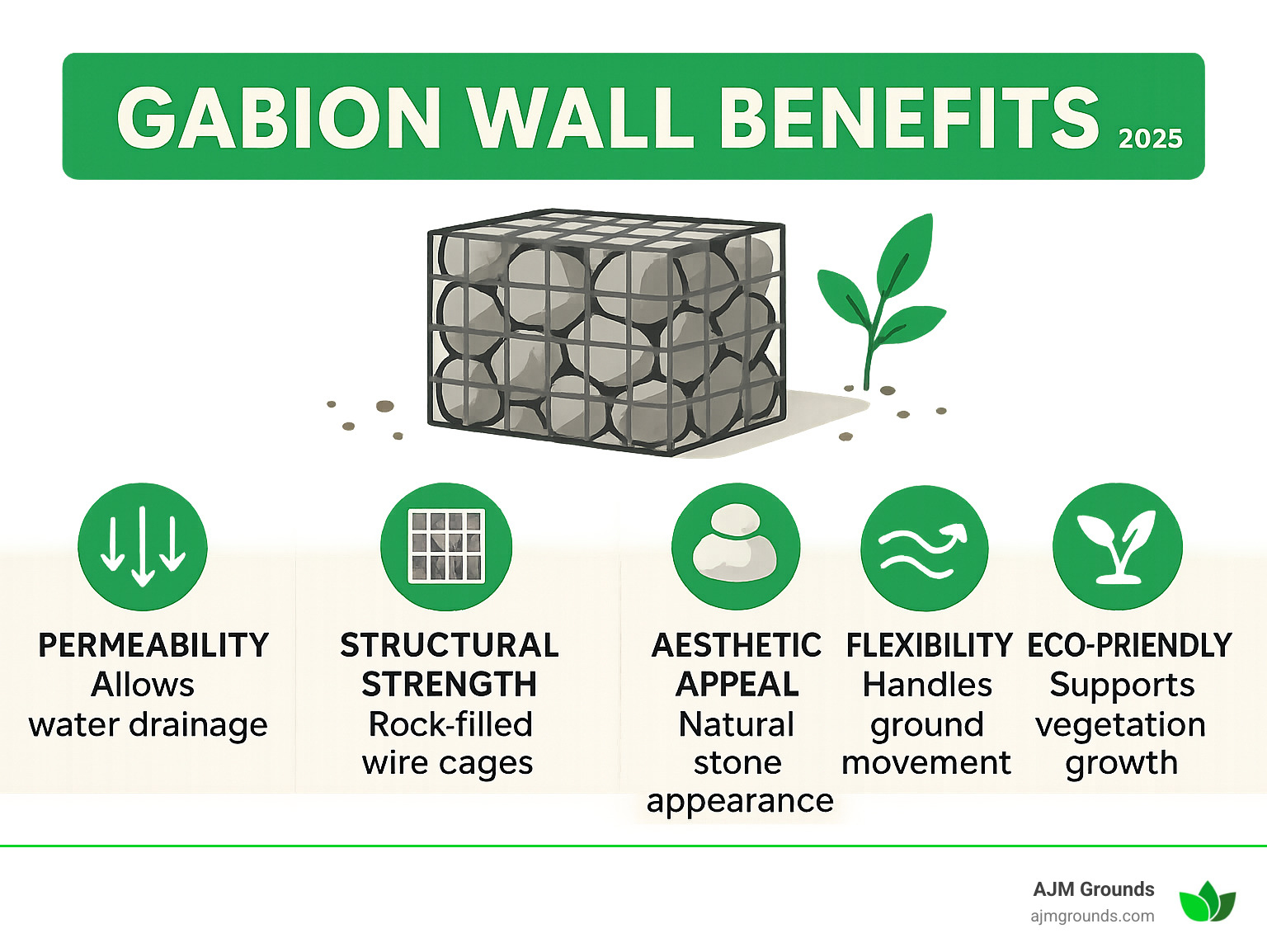

Installing a gabion retaining wall means filling sturdy, galvanized wire cages with rock to create a retaining structure that is strong, permeable, and good-looking. Because the baskets arrive flat-packed, many homeowners can assemble and fill them over a single weekend.

Quick Installation Overview:

- Prepare the site – excavate 20-50 cm to firm sub-soil.

- Create a foundation – add 20 cm of compacted gravel.

- Assemble baskets – unfold and connect the wire mesh panels.

- Fill with rocks – 4-8 inch angular stones for 3 × 3 inch mesh.

- Install bracing – at least four braces per m² to stop bulging.

- Stack layers – tie upper baskets securely to those below.

- Backfill & drain – geotextile plus drainage gravel behind the wall.

Why choose gabions instead of block or poured-concrete walls?

- Excellent drainage—water passes straight through.

- Flexible—minor ground movement won’t crack the wall.

- Cost-effective—no mortar, forms, or heavy machinery required.

- Eco-friendly—natural stone can be reclaimed and supports vegetation.

- DIY-friendly—basic hand tools get the job done.

Most Massachusetts communities allow walls up to 1 m (3.3 ft) without a permit; taller structures often need engineering approval and, in some cases, support posts.

As John Caplis, owner of AJM Grounds LLC, my team has solved slope and drainage problems for clients from Woburn to Winchester by installing gabion retaining wall systems that marry strength with New England’s natural stone look.

Need more inspiration? Browse our guides on retaining walls ideas, block retaining wall design, and how to install a block retaining wall.

Before You Dig: Planning Your Gabion Retaining Wall Project

Here’s the truth about installing a gabion retaining wall: the secret to success isn’t in the building – it’s in the planning. After years of helping homeowners in Woburn and surrounding areas tackle challenging slopes, I’ve learned that a well-planned project runs smoothly, while a rushed one leads to headaches, extra costs, and sometimes having to start over.

Think of planning like getting directions before a road trip. You could just start driving and figure it out as you go, but wouldn’t you rather know exactly where you’re headed?

Checking Local Permits and Regulations

Before you touch a shovel, make friends with your local building department. Trust me on this one – it’s much easier to get permits upfront than to explain why you didn’t get them later.

Height restrictions are your first consideration. Most Massachusetts communities allow gabion walls up to 1 meter (3.3 feet) without permits, but every town has its own rules. What flies in Bedford might not work in Winchester or Stoneham.

Property line setbacks matter too. Your beautiful new wall shouldn’t become a neighbor dispute. Check how close you can build to property lines, and when in doubt, measure twice and build once.

Here’s something that catches many DIYers off guard: utility line locations. Call 811 before you dig – it’s free, it’s the law, and it could save your life. Underground cables, gas lines, and water pipes don’t announce themselves until it’s too late.

For walls over 2 meters (6.6 feet), you’ll likely need professional engineering. These taller structures create significant soil pressure, and local authorities want to ensure they’re safe for everyone.

Essential Tools and Materials for the Job

Getting organized before you start makes the difference between a smooth project and a frustrating one. You don’t need a contractor’s workshop, but having the right tools on hand keeps momentum going.

Safety comes first – invest in quality safety glasses and heavy-duty leather gloves. Gabion work involves sharp wire and heavy rocks, so protect yourself properly.

Your digging arsenal should include both flat and spade shovels, a rake, and a pick for tough spots. A wheelbarrow becomes your best friend when moving rocks and gravel. You’ll also need a tape measure, 4-foot level, and string line with stakes for keeping everything straight and true.

Wire work requires specific tools – good pliers with wire cutters are essential, though specialized hog ring pliers make assembly much easier. A heavy hammer helps with stubborn connections.

The plate compactor might be your only rental item, but it’s crucial for proper foundation preparation. Don’t skip this step – loose foundations lead to settling walls.

Material selection starts with choosing the right gabion baskets for your project. Geotextile fabric goes behind the wall to prevent soil loss, while perforated drainage pipe handles water management. You’ll need Type 1 basecourse or crushed stone for the foundation, plus lacing wire, spiral wire or ring fasteners for assembly.

Choosing the Right Gabion Baskets and Rock Fill

This is where many DIYers get overwhelmed, but it’s actually straightforward once you understand the basics.

Welded mesh baskets offer strength and rigidity – perfect for decorative applications where appearance matters. Woven mesh provides flexibility and costs less, making it ideal for larger engineering projects where function trumps form.

Coating quality determines how long your wall lasts. Look for Galfan coating, which outlasts standard galvanized wire by four times. It’s worth the extra cost for long-term durability.

Mesh and rock sizing must work together. For 3×3 inch mesh, use 4-8 inch rocks – anything smaller falls through the gaps. 6×8 type mesh needs 75mm (3 inches) minimum rock size, while 8×10 type mesh works with 100-250mm (4-10 inches) rocks.

Rock selection affects both cost and performance. Angular rocks interlock better than rounded ones, creating stronger walls. Granite, basalt, and hard limestone provide excellent durability and weather resistance.

Here’s a money-saving tip from our Hardscaping experience: use cheaper rubble in the core and decorative stone on visible faces. This approach cuts costs significantly while maintaining the beautiful appearance you want.

Rock density should hit 2400 kg/m³ (150 lbs/ft³) or higher for structural integrity. Local stone often provides the best value and naturally complements the Massachusetts landscape.

Planning might not be the most exciting part of installing a gabion retaining wall, but it’s what separates successful DIY projects from expensive do-overs. Take time to get permits, gather proper tools, and select quality materials. Your future self will thank you when everything goes smoothly.

For complex projects or when you need professional guidance, our Natural Stone Retaining Walls expertise can help you steer the planning process and ensure your project meets all local requirements.

The Step-by-Step Guide to Installing a Gabion Retaining Wall

Now comes the exciting part – actually building your wall! Think of installing a gabion retaining wall like assembling a giant LEGO set, except instead of tiny plastic bricks, you’re working with wire cages and rocks. Don’t worry though – it’s far more forgiving than those impossible-to-follow furniture instructions!

We’ll walk you through each step, sharing the techniques we’ve refined over years of Retaining Wall Construction projects throughout the greater Woburn area. The key to success lies in taking your time and getting each step right before moving to the next.

Step 1: Site and Foundation Preparation

The foundation is everything – literally. A wobbly foundation means a wobbly wall, and nobody wants their beautiful gabion structure doing the cha-cha after the first heavy rain.

Start by marking your wall location using spray paint or stakes and string. This isn’t the time to eyeball it – precision here saves headaches later. Dig down 20-50cm (8-20 inches) until you reach solid, firm subsoil. You’ll know you’ve hit the good stuff when your shovel stops sinking like it’s in quicksand.

For walls that will be doing some serious soil-holding work, create a 6-degree backward slope – think of it as giving your wall a comfortable lean-back position. Remove all vegetation, roots, and loose topsoil because plants are sneaky little wall-undermining troublemakers.

Foundation depth matters more than you might think. Retaining walls should start 50cm (20 inches) below ground level for regulated structures, though for walls up to 2m (6.6 feet), digging 20-50cm deep is generally sufficient. If you’re dealing with sandy or clay soil, replace it with 6 inches of compacted gravel or consider a concrete footer.

Creating the gravel base is where things get satisfying. Add a 20cm (8-inch) layer of Type 1 basecourse – crushed granite, limestone, or basalt all work beautifully. Compact it thoroughly using a plate compactor (the machine that sounds like an angry lawnmower but actually loves you). Check for level using a 4-foot level and ensure proper drainage slope away from the wall.

Finally, place geotextile fabric on your prepared foundation, with excess material draped along the backfill area. This prevents soil migration and maintains proper drainage – think of it as a protective blanket for your foundation.

Step 2: Assembling and Placing the Baskets

Time to turn those flat-packed wire panels into actual baskets! Unfold each gabion basket on flat ground first – trying to assemble them in their final position is like trying to gift-wrap a present while wearing oven mitts.

Raise the sides, ends, and diaphragms to form the box shape. It should start looking like a shopping cart that’s been hitting the gym. Connect panels using galvanized spiral wire or ring fasteners, ensuring all connections are tight with maximum spacing of 200mm (8 inches) for fasteners.

Here’s where teamwork pays off: lace baskets together at every contact edge using alternating double and single loops. Space these lacing loops approximately 150mm (6 inches) apart. This creates a monolithic structure that acts as one unit – like a rock-filled chain mail armor for your hillside.

Alignment and leveling are crucial at this stage. Use a string line to ensure proper alignment, and check that baskets lean back 5-6 degrees toward the retained soil. Verify level in both directions before filling because trying to adjust a basket full of rocks is like trying to rearrange furniture with an elephant sitting on it.

Step 3: The Art of Filling and Bracing for a Bulge-Free Wall

This is where patience becomes your best friend. Proper filling technique prevents bulging and ensures your wall looks like it was built by professionals rather than enthusiastic amateurs.

Hand-place your face stones first – use your best-looking rocks on visible faces because these are your wall’s Instagram-worthy shots. Fill the core with cheaper materials like recycled concrete or brick rubble. Nobody sees what’s inside, so save your budget for the pretty stuff.

Layer filling is the secret sauce here. Fill in 1/3 increments, never allowing one cell to be more than 0.3m higher than adjacent cells. Think of it like building a layer cake – you wouldn’t pile all the frosting on one side, would you?

Bracing wire installation prevents your wall from developing an unfortunate belly. Install a minimum of 4 bracing wires per square meter of front face. For 1-meter deep gabions, fix bracing wires at 1/3 and 2/3 of the total depth. Thread wire from front to back, securing to mesh on both sides.

Use angular rocks for better interlocking – round rocks are like marbles in a bag, but angular ones lock together like puzzle pieces. Fill tightly to minimize voids and overfill by 25-50mm (1-2 inches) to allow for natural settlement. Take care not to damage the wire coating during filling because even tough wire doesn’t like being beaten up.

Step 4: Managing Drainage and Backfilling

Here’s where we get serious about water management. Poor drainage is the number one cause of retaining wall failure – it’s like kryptonite to your gabion superhero.

Install an 80mm (3-inch) perforated drainage pipe along the back of the bottom row. Wrap this pipe in non-woven geotextile to prevent clogging – think of it as giving your drainage system a protective sock. Cover with 300-400mm (12-16 inches) of gravel and ensure the pipe slopes toward a suitable drainage outlet.

Pull non-woven geotextile up behind the gabion baskets to prevent clay and fine soil from clogging your drainage system. Secure the fabric to prevent displacement during backfilling – loose fabric is about as useful as a chocolate teapot.

Backfilling must be done simultaneously with gabion installation. Use a minimum of 2 compaction layers for 50cm high units and 3 compaction layers for 1-meter high units. Keep heavy machinery (over 1500kg/3300lbs) at least 1 meter from the gabion face – your wall doesn’t appreciate being bullied by bulldozers.

Our experience with Landscape Retaining Wall projects has taught us that proper drainage can make the difference between a wall that lasts decades and one that fails within a few years.

Step 5: Stacking Tiers and Finishing Your Masterpiece

Time to add height and put the finishing touches on your creation! Position the second row directly above the first and stagger vertical seams for better structural integrity – it’s like laying bricks but with much bigger, wire-wrapped bricks.

Connect layers using helical spirals or lacing wire, weaving front connectors through both the lid of the lower basket and the base of the upper basket. This creates a continuous connection that would make a rock climber jealous.

Lace all lids securely along edges, ends, and diaphragms. Turn in all wire ends for safety because nobody wants to snag their favorite gardening gloves on protruding wire. Perform final alignment checks and complete backfilling and grading.

For comprehensive guidance on advanced techniques, check out this detailed guide on building with gabions.

Installing a gabion retaining wall is like conducting an orchestra – every element needs to work in harmony. When done right, you’ll have a structure that’s not only functional but also adds natural beauty to your landscape for years to come.

Advanced Techniques and Troubleshooting

Even the most carefully planned gabion wall project can throw you a curveball. After years of helping homeowners throughout the Woburn area tackle challenging terrain, we’ve learned that knowing how to handle these tricky situations separates the pros from the weekend warriors. Don’t worry though – with the right techniques, you can steer these challenges like a seasoned contractor!

How to Prevent Common Issues When Installing a Gabion Retaining Wall

The most frustrating part of installing a gabion retaining wall is watching your hard work develop problems that could have been easily prevented. Let’s tackle the big ones before they become headaches.

Bulging baskets are probably the most common issue we see. Picture this: you’ve spent all weekend carefully placing rocks, only to find your wall looking like it’s been inflated with a bicycle pump! The secret is proper bracing – install those bracing wires at maximum 14-inch intervals in both directions. Think of them as the wall’s internal support system, like the underwire in a bra (but way more visible and definitely not as comfortable to install).

Fill your baskets in stages, never letting one section get too far ahead of its neighbors. This prevents uneven pressure that causes bulging. Angular rocks that interlock well are your best friend here – they grip each other like puzzle pieces, creating a solid mass that won’t shift under pressure.

Wall stability comes down to basic physics and good planning. The golden rule is maintaining a 2:1 height-to-base ratio – your wall height should never exceed twice the base width. It’s like building a pyramid; the wider the base, the more stable your structure. Create that solid, level foundation we talked about earlier, and don’t forget to lean your wall back 5-6 degrees toward the retained soil. This slight backward tilt works with gravity instead of against it.

Settlement prevention starts with thorough foundation preparation. We can’t stress this enough – compact that foundation like your wall’s life depends on it (because it does!). Use proper gradation of base materials, and remember that adequate drainage prevents soil saturation that can undermine your foundation. Always overfill your baskets by 1-2 inches to account for natural rock settlement over time.

The biggest mistakes we see are skipping the geotextile fabric (hello, soil migration!), inadequate bracing (bulging city, population: your wall), poor foundation prep (settlement central), and insufficient drainage (hydrostatic pressure is not your friend).

Adapting Your Wall: Building Curves, Corners, and Around Pipes

Real-world landscapes rarely cooperate with straight-line construction plans. Fortunately, gabion walls are surprisingly adaptable when you know the tricks.

Creating smooth curves is easier than you might think. Gabion baskets can naturally conform to gentle bends with a radius of 18-21 meters (59-69 feet) without any modifications. For tighter curves, you’ll need to get creative by cutting and folding the mesh on-site. Use shorter basket lengths for better curve conformity – think of it like trying to bend a long ruler versus a short one.

Building solid corners requires overlapping baskets at corner points for maximum strength. L-shaped configurations work perfectly for 90-degree corners, while specially designed corner units handle complex angles. The key is maintaining proper lacing at all corner connections – these junction points bear extra stress and need that extra attention.

Working around existing utilities is where things get interesting. Pipes with diameters less than 400mm (16 inches) can penetrate gabion units if you cut the mesh carefully around them and seal the opening. For pipes that might move or expand, use flexible connections. Our Retaining Walls for Slopes projects have taught us that sometimes it’s worth rerouting utilities for a cleaner, stronger installation.

These advanced techniques often separate a functional wall from a truly professional-looking installation. Take your time, think through each challenge, and don’t be afraid to adapt your approach when the situation calls for it.

Frequently Asked Questions about Gabion Wall Installation

How high can I build a gabion wall without an engineer?

The general rule of thumb is that DIY gabion walls should stay under 1 meter (3.3 feet) in height without professional engineering. However, this varies by location and soil conditions.

Height considerations:

- Walls under 1 meter: Usually no permit required

- Walls 1-2 meters: May require permits and engineering review

- Walls over 2 meters: Almost always require professional engineering

When to consult professionals:

- Retaining significant soil loads

- Building on poor soil conditions

- Walls near property lines

- Complex drainage situations

- Local building codes require it

For complex projects requiring professional expertise, consider our Retaining Wall Builders Near Me services.

Do I need a concrete foundation for a gabion wall?

Most gabion walls don’t require concrete foundations. The flexibility of gabions actually works better with compacted gravel bases in most situations.

When concrete foundations are recommended:

- Very soft clay or sandy soil conditions

- High water table areas

- Walls supporting heavy loads

- Engineering specifications require it

Why gravel is often preferred:

- Allows natural drainage

- Accommodates slight ground movement

- More cost-effective

- Easier to adjust if needed

However, concrete foundations can interfere with the natural drainage benefits of gabion walls, so they should only be used when absolutely necessary.

How much does installing a gabion retaining wall cost?

These are average costs based on internet data and not actual costs for AJM Grounds.

Material costs (DIY):

- Gabion baskets: $15-50 per linear foot

- Rock fill: $30-100 per ton

- Geotextile fabric: $1-3 per square foot

- Drainage materials: $20-40 per linear foot

- Total materials: $50-200 per linear foot

Professional installation costs:

- Labor: $25-75 per square foot

- Total installed cost: $75-300 per linear foot

- Complex projects: $200-900 per linear foot

Factors affecting cost:

- Wall height and complexity

- Rock type and availability

- Site accessibility

- Local labor rates

- Permit requirements

- Drainage complexity

For a 50-foot wall that’s 3 feet high, expect material costs of $2,500-$10,000 for DIY, or $11,250-$45,000 for professional installation.

Conclusion: Your Rock-Solid Retaining Wall is Complete

Congratulations—you have turned flat-packed wire baskets and a pile of stone into a durable structure that will serve your landscape for decades. Careful planning, a compacted gravel foundation, tight basket connections, layered filling with bracing wires, and a reliable drainage system are the keys to a long-lasting gabion wall.

Some projects still require professional help. Walls taller than 3 ft, sites with poor soils, or complicated drainage scenarios often need engineering calculations and specialized equipment. If your project fits that description—or if you simply prefer to leave the heavy lifting to pros—AJM Grounds is ready to help. Our team has built countless retaining walls across Woburn, Burlington, Lexington, and the surrounding Massachusetts towns, always with the attention to detail and personalized service our clients expect.

Keep an eye on your new wall during the first year, especially after heavy rains or spring thaw. Clear leaves from drainage outlets and add landscaping to integrate the wall into your overall design.

When you are ready for your next hardscape upgrade, explore our full range of Retaining Wall Construction and Hardscape Construction Service options. We’d be happy to help you build the outdoor space you’ve been dreaming about.