Why Installing Flagstone on Concrete Creates the Most Durable Walkway

Learning how to install flagstone walkway in concrete gives you the strongest, longest-lasting path for your home. This method combines the natural beauty of stone with a rock-solid foundation that won’t shift, settle, or develop gaps over time.

Quick Answer – How to Install Flagstone Walkway in Concrete:

- Clean and prep the concrete surface with pressure washing

- Apply bonding agent or cement slurry for better adhesion

- Spread mortar bed ¼-1 inch thick with 100% coverage

- Set flagstones by tapping with rubber mallet, maintaining ½-1 inch joints

- Grout joints after 24-hour cure time

- Allow 48 hours before heavy foot traffic

A concrete base costs more upfront but eliminates the maintenance headaches of sand-set installations. As one experienced contractor noted: “The stones have not budged in 13 years and I suspect they will still look swell 50 years from now.”

The concrete method works best when you need:

– Maximum durability in freeze-thaw climates

– Level surface that stays put

– Minimal long-term maintenance

– Professional appearance with tight joints

I’m John Caplis, owner of AJM Grounds LLC in Woburn, Massachusetts, where I’ve helped homeowners transform their outdoor spaces for years. My team specializes in hardscaping installations including how to install flagstone walkway in concrete, ensuring every project delivers both beauty and lasting performance.

Handy how to install flagstone walkway in concrete terms:

– dry laid flagstone walkway

– installing a stepping stone walkway

– patio installation company

Plan, Drain & Design for Success

Getting your planning right from the start makes all the difference when learning how to install flagstone walkway in concrete. I always tell homeowners that spending extra time on design prevents costly mistakes later.

Start by marking your walkway with layout stakes and spray paint. This gives you a clear picture of how the path will flow through your landscape. Walk the route several times—you might find that shifting the path a few feet makes it more practical for daily use.

Drainage is absolutely critical for long-term success. Your walkway needs a ¼-inch slope per foot away from your house. This might not sound like much, but it prevents water from pooling and protects your foundation. Here in Massachusetts, we see what happens when drainage goes wrong—freeze-thaw cycles can crack both concrete and stone if water gets trapped.

If you’re working with an existing concrete slab, give it a thorough inspection first. Minor hairline cracks are usually fine, but major damage needs fixing before you start. I’ve seen beautiful flagstone installations fail because the underlying concrete wasn’t solid. It’s heartbreaking to watch months of work crumble because someone skipped this step.

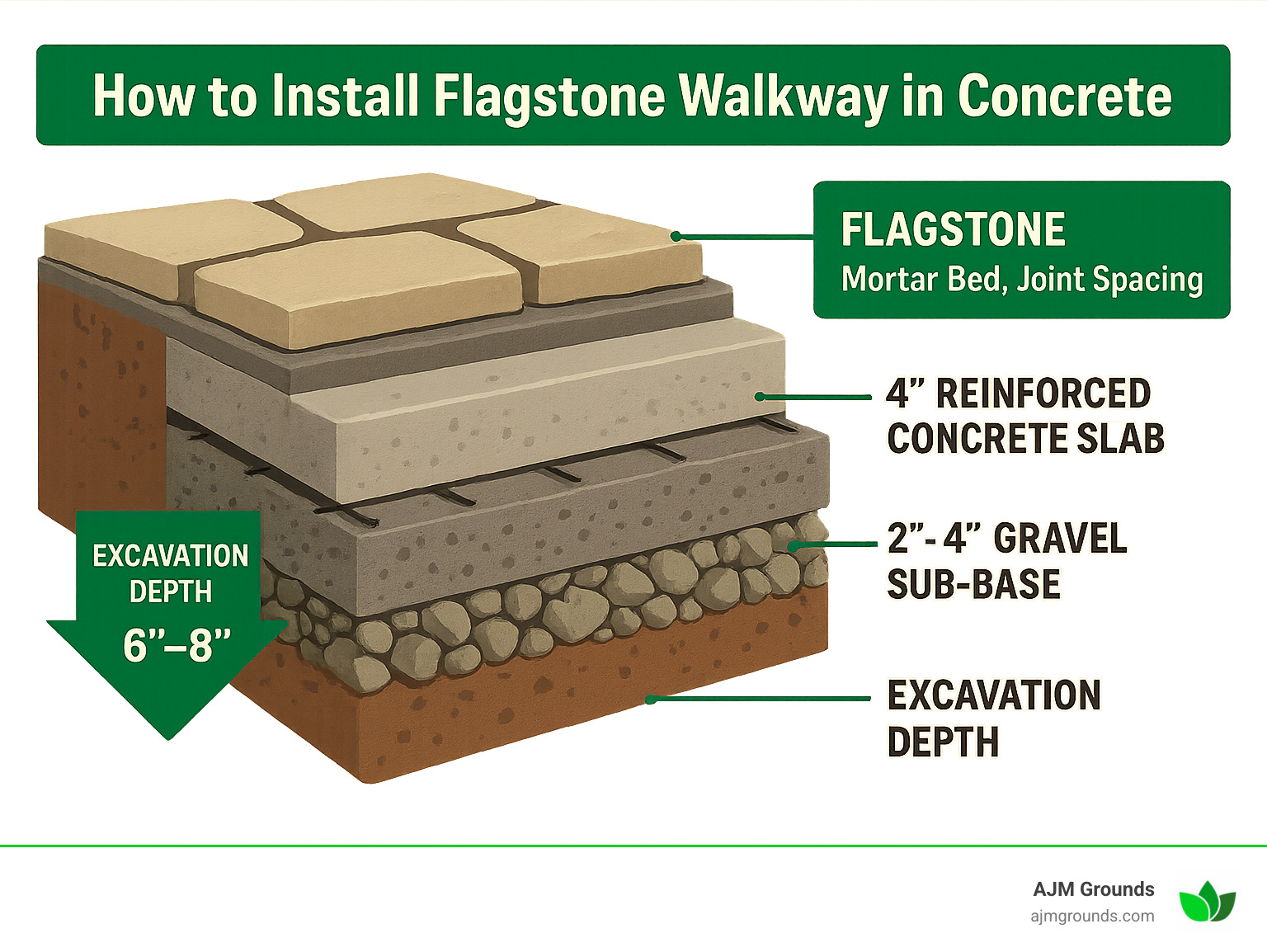

For new installations, plan your excavation carefully. You’ll need 8 inches total depth: 2-4 inches of compacted gravel, 4 inches of reinforced concrete, plus your mortar bed and flagstone thickness. The gravel base prevents settling, while the concrete provides the rock-solid foundation that makes this method so durable.

Steel mesh reinforcement is non-negotiable for a professional installation. Position it 1½-2 inches above the subgrade so it sits in the middle of your concrete pour. This prevents cracking and gives your walkway the strength to handle decades of foot traffic and weather.

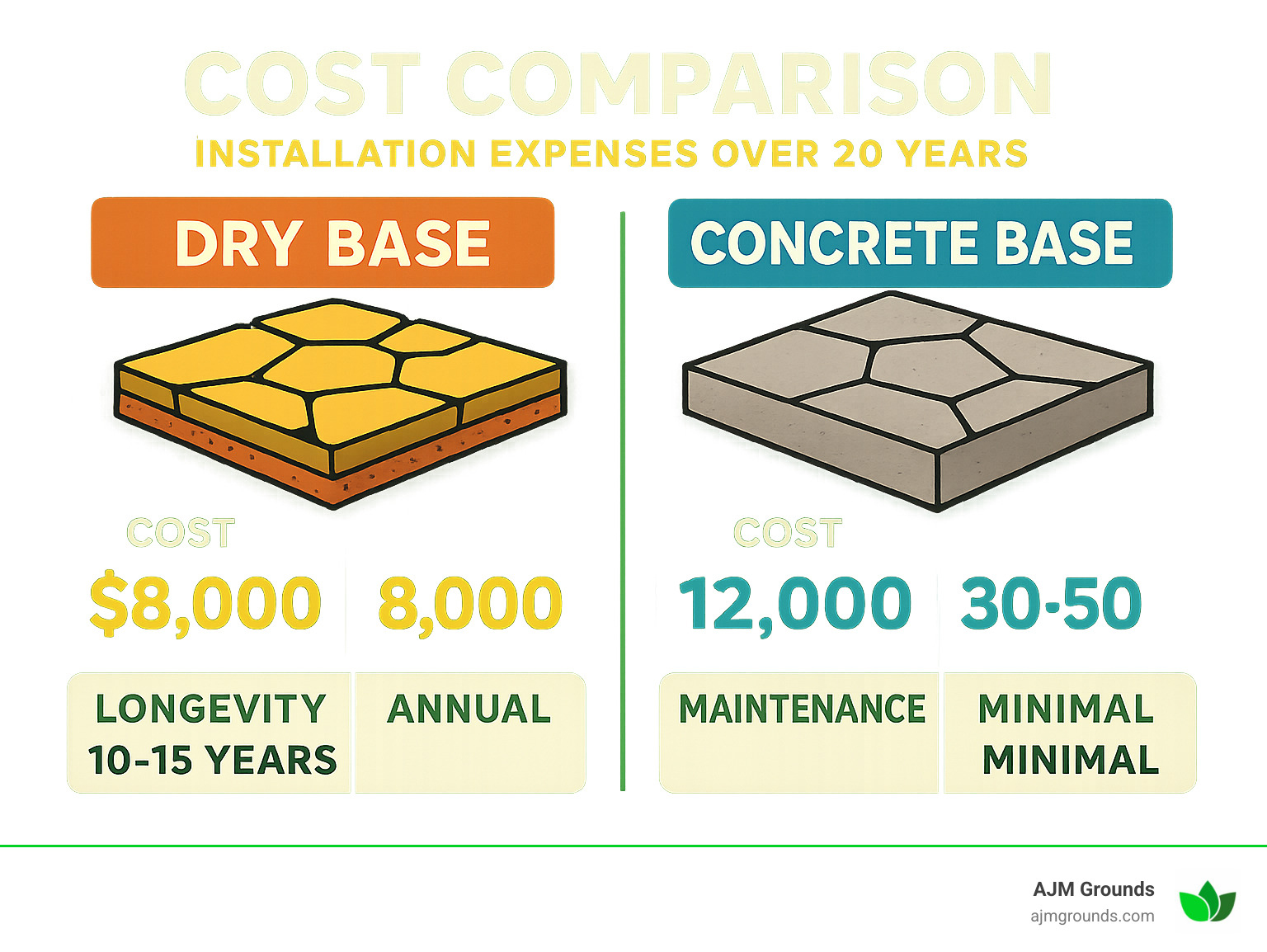

The concrete base method has clear advantages: superior durability in freeze-thaw climates, minimal long-term maintenance, and that polished professional look that adds real value to your home. The trade-offs include higher upfront costs, a more complex installation process, and the fact that repairs require more effort than with sand-set installations.

But here’s the thing—when you consider the long-term picture, the concrete method usually wins. Sand-set installations might cost less initially, but they require annual maintenance and eventual rebuilding.

For detailed guidance on professional installation options, check out our Walkway Installation services.

Choosing Your Build Method

The choice between dry-lay and mortar methods shapes everything about your project—from installation complexity to how much time you’ll spend maintaining it years from now.

Dry-lay installations appeal to many DIYers because they’re simpler and cost less upfront. The stones sit on a sand base, which allows for seasonal movement and makes individual stone replacement easier. However, this flexibility comes with ongoing maintenance needs—annual re-leveling, joint sand replacement, and dealing with ant infiltration that can undermine your work.

The mortar-on-concrete approach requires more skill and investment initially, but delivers maximum stability and durability. Once properly installed and cured, your walkway can last 50+ years with minimal maintenance. The tight, grouted joints create a professional appearance that significantly boosts curb appeal.

Climate plays a huge role in this decision. In our Massachusetts freeze-thaw environment, concrete-based installations consistently outperform sand-set alternatives. As one experienced installer put it: sand-set flagstone is vulnerable to washout and pest infiltration, while concrete installations maintain their integrity through decades of harsh weather.

The permanence of the concrete method means you need to get the design right the first time—modifications later are challenging and expensive. But for most homeowners, this trade-off makes sense when you consider the peace of mind that comes with a truly permanent installation.

Tools, Materials, Cost & Quantity Estimator

Getting the right tools and materials upfront makes learning how to install flagstone walkway in concrete much smoother. After years of professional installations, I’ve learned that having everything ready prevents those frustrating mid-project trips to the hardware store.

You’ll need a rubber mallet for gently setting stones without chipping edges, plus an angle grinder with diamond blade for precise cuts. A 4-foot level helps maintain proper slope, while a trowel spreads mortar evenly. Don’t forget a grout bag for filling joints cleanly and a sponge for the final cleanup.

For surface preparation, a pressure washer removes dirt and debris that could prevent proper bonding. You’ll also want a wheelbarrow for mixing mortar and essential safety gear—goggles, gloves, and a dust mask are non-negotiable when cutting stone.

Type S mortar forms the backbone of your installation, mixed at a ratio of 2 parts sand to 1 part Portland cement. Adding a bonding agent or latex additive creates stronger adhesion to the concrete base. 6×6 steel reinforcement mesh strengthens the concrete slab, while stone sealer protects your finished walkway from weather and stains.

Coverage formulas help you order the right amounts. 1 ton of flagstone typically covers 75-100 square feet, depending on thickness. Thinner stones cover more area but thicker stones last longer—it’s always a trade-off.

These are average costs based on internet data and not actual costs for AJM Grounds services. Prices may vary three-fold based on region, material grade, and project complexity.

Average DIY costs range from $12–$40 per square foot for basic installations, though premium materials can push costs to $75+ per square foot. Basic flagstone runs $8-$25 per square foot, while premium varieties cost $15-$45. Add $2-$5 per square foot for mortar and supplies, plus $50-$150 daily for tool rental if you don’t own them.

| Method | Material Cost | Labor Difficulty | Longevity | Maintenance |

|---|---|---|---|---|

| Dry Base | $8-$20/sq ft | Moderate | 10-15 years | Annual |

| Concrete Base | $15-$45/sq ft | High | 30-50 years | Minimal |

Ordering Stone & Mortar

Accurate measurements prevent costly delays or embarrassing shortages. Measure your walkway’s length and width, multiply for total square footage, then add 5% for waste—cutting and occasional breakage are inevitable.

Stone thickness matters more than you might think. Use minimum 1½ inches for walkways and 2 inches for heavy traffic areas. Thicker stones cost more upfront but dramatically reduce cracking and chipping over time.

For mortar quantities, plan for ½-1 inch bed thickness under each stone. One 94-pound bag of Portland cement mixed with appropriate sand covers about 12-15 square feet at ¾-inch thickness. Always buy extra mortar—running out mid-project creates visible color differences in your finished joints.

A simple yardage calculator helps: multiply length × width × depth (in feet) ÷ 27 for cubic yards needed. Round up to the nearest half-yard, because concrete trucks can’t deliver partial loads.

How to Install Flagstone Walkway in Concrete

Learning how to install flagstone walkway in concrete transforms from overwhelming to manageable when you break it into clear steps. The process requires patience and attention to detail, but the reward is a walkway that can last 50+ years with minimal maintenance.

The secret to professional results lies in achieving 100% mortar coverage under each stone. As experienced installers know: “Mortar bedding should be at least ¼ inch thick at the shallowest point with 100% coverage under each stone for best adhesion.” Skip this step, and you’ll have loose stones within a few seasons.

Joint width consistency also makes or breaks the visual appeal. Maintain ½-1 inch spacing throughout, and your walkway looks intentional and polished. Let joints vary randomly, and even premium stone looks amateur.

The entire process from surface prep to final curing takes 3-4 days minimum. Don’t rush—each step needs proper time to cure for maximum strength and longevity.

For detailed technical guidance on advanced techniques, this stone-setting guide provides professional insights that complement our practical approach.

Step 1 – Surface Prep for how to install flagstone walkway in concrete

Surface preparation determines whether your flagstone installation survives its first winter or lasts decades. We’ve seen beautiful stonework fail simply because someone skipped the cleaning and bonding steps.

Start with thorough pressure washing of the entire concrete slab. Remove every trace of dirt, oil, leaves, and loose concrete. What looks clean to the naked eye often hides a film that prevents proper mortar adhesion. Allow a full 24 hours for complete drying—trapped moisture weakens the bond.

Create texture on smooth concrete surfaces using a hammer and chisel. You’re not trying to damage the concrete, just roughen it enough for the mortar to grip. Create shallow dimples every 6 inches across the surface. Think of it as giving your mortar something to grab onto.

Wash your flagstones too—the backs often carry quarry dust that interferes with bonding. A quick rinse and dry makes a significant difference in how well they adhere to the mortar bed.

The final step involves applying bonding slurry—a mixture of Portland cement and water painted onto the concrete surface just before spreading mortar. This creates both mechanical and chemical bonds that dramatically improve long-term adhesion.

Step 2 – Mix & Spread Mortar Bed

Getting the mortar mix right makes the difference between stones that stay put and stones that pop loose after the first freeze. We use a 2-to-1 ratio of concrete sand to Portland cement, improved with latex bonding additive for extra strength and flexibility.

Mix to a stiff but workable consistency—think thick peanut butter rather than soup. Too wet, and the mortar loses strength as excess water evaporates. Too dry, and you can’t achieve full coverage under the stones.

Work in small sections of 5-6 stones at a time. Spread mortar ½-1 inch thick with a trowel, creating slight ridges that help with stone seating. The key is 100% coverage—no air pockets or gaps that allow water infiltration and freeze damage.

Never let mortar skin over before setting stones. In hot weather, this happens quickly, so have your stones ready and work efficiently. Keep the concrete base slightly damp during application to prevent rapid moisture loss from your fresh mortar.

Step 3 – Lay, Cut & Fit Stones

Stone placement combines puzzle-solving skills with technical precision. Start by dry-fitting your pattern before mixing any mortar. This lets you identify which stones need cutting and ensures you’re happy with the overall layout.

Begin with your largest, most prominent stones and work systematically from one end to the other. These anchor pieces set the tone for the entire walkway. Maintain consistent ½-1 inch joint widths—use wood spacers if needed to keep everything uniform.

Cutting flagstone requires an angle grinder with a diamond blade. Score both sides of the stone before making the final cut, and always wear safety equipment. Stone dust is harmful to breathe and sharp fragments can cause injury. Cut stones slightly oversized and grind to final fit for the tightest joints.

Set each stone by placing it on the mortar bed and tapping gently with a rubber mallet. Check level frequently with a 4-foot level, maintaining that critical ¼-inch per foot slope for drainage. Remove excess mortar immediately from stone surfaces and keep joint spaces clean—this makes grouting much easier later.

Step 4 – Grouting & Finishing in how to install flagstone walkway in concrete

Joint grouting provides the finished appearance and weather seal that completes your flagstone walkway in concrete. This final step requires patience—rushing creates messy results that detract from otherwise beautiful stonework.

Wait a full 24 hours after stone setting before grouting. The mortar bed needs time to develop initial strength. Mix your grout using equal parts Portland cement and fine sand, adding water to create a soupy consistency that flows easily into joints.

Use a grout bag for clean, professional application. Fill joints completely, slightly overfilling, then tool with a trowel for consistent appearance. Clean stone surfaces immediately with a damp sponge—cured mortar is extremely difficult to remove from stone faces.

Protect your finished work by covering with plastic if rain threatens and keeping foot traffic off for 48 hours minimum. Light misting helps joints cure properly, especially in hot, dry weather.

The most common mistake is grouting too soon before the mortar bed has set properly. This can disturb stone placement and create weak joints that crack during the first freeze-thaw cycle. Take the time to do it right—your walkway will thank you with decades of trouble-free service.

Cure, Seal, Maintain & Troubleshoot

The real test of learning how to install flagstone walkway in concrete comes after installation—proper curing and maintenance determine whether your beautiful walkway lasts 10 years or 50 years. After completing hundreds of installations across Massachusetts, I’ve seen what works and what doesn’t.

Your walkway needs time to reach full strength. Allow 48 hours for light foot traffic before walking normally on your new flagstone. For heavy items like furniture or snow blowers, wait a full week. The mortar continues gaining strength during this period, and rushing can cause loose stones or cracked joints.

Sealing protects your investment. Apply a penetrating stone sealer every 2-3 years to shield against Massachusetts’s harsh freeze-thaw cycles. The sealer prevents water from penetrating the stone and mortar, which is crucial since trapped water can crack joints when it freezes. Choose a penetrating sealer rather than a surface coating—it protects without changing the stone’s natural appearance.

Simple maintenance keeps your walkway looking great. Sweep debris regularly to prevent organic stains from decomposing leaves. A monthly rinse with your garden hose removes surface dirt and prevents buildup. When you spot weeds growing in joints, pull them immediately—their roots can gradually widen cracks in the mortar.

Winter care requires special attention in our New England climate. Use calcium chloride ice melt instead of rock salt, which can damage both stone and mortar. When possible, apply sand for traction rather than any ice melt. Shovel promptly after storms to prevent thick ice buildup that can stress the joints.

Troubleshooting common problems saves money and frustration. Loose stones usually mean insufficient mortar coverage during installation—remove the stone, clean both surfaces thoroughly, and reset with fresh mortar ensuring 100% contact. Cracked joints often result from freeze-thaw cycles or minor settling, requiring removal of damaged grout and repointing with fresh mortar.

That white film appearing on new installations is called efflorescence—mineral deposits from the curing mortar that are completely normal. Clean it with a mild muriatic acid solution after the mortar fully cures, following all safety precautions.

Prevention beats repair every time. Most problems stem from shortcuts during installation—insufficient mortar coverage, poor surface prep, or inadequate curing time. When we encounter uneven stones on service calls, it’s usually because someone didn’t check level frequently enough during installation.

For comprehensive hardscape maintenance and repair services, visit our Hardscape Installation Service page.

Built-In FAQs

1. How long should I wait before heavy use of my new flagstone walkway?

Wait at least 48 hours for normal foot traffic and 7 days before allowing heavy loads like furniture or equipment. The mortar needs this time to achieve full strength. In cooler weather, extend these times by 50%.

2. Is sealing necessary for flagstone installed on concrete?

Yes, sealing protects both the stone and mortar joints from water penetration, freeze-thaw damage, and staining. Apply a penetrating sealer (not film-forming) every 2-3 years for best results.

3. Can I install flagstone over cracked concrete slabs?

Minor cracks are acceptable, but major structural damage must be repaired first. Cracks wider than ¼ inch or areas with significant settlement will telegraph through to your flagstone installation, causing future problems.

Conclusion

Mastering how to install flagstone walkway in concrete transforms your outdoor space with a pathway that combines natural beauty with rock-solid durability. This investment pays dividends for decades—while the upfront costs and technical demands are higher than sand-set alternatives, you’ll enjoy minimal maintenance and professional results that withstand New England’s toughest weather.

The concrete base method isn’t just about longevity—it’s about peace of mind. No more annual re-leveling, no ant invasions, and no washout repairs after heavy rains. Your flagstone stays exactly where you placed it, maintaining that crisp, professional appearance year after year.

Success comes down to getting the fundamentals right: thorough surface preparation creates the foundation for everything else, while 100% mortar coverage under each stone prevents the hollow spots that lead to cracking. Consistent joint spacing and patient curing time separate amateur work from installations that look professionally done.

The choice between DIY and professional installation depends on your comfort level with technical work and tolerance for potential do-overs. At AJM Grounds, we’ve seen enthusiastic homeowners create beautiful results—and we’ve also rescued projects where good intentions met harsh reality. Our attention to detail and personalized service ensure every flagstone walkway meets the exacting standards that Massachusetts weather demands.

Cost considerations vary dramatically based on your location, material choices, and project complexity. DIY installations typically range from $12-$75 per square foot, with premium materials and complex layouts reaching the higher end. These are average costs based on internet data and may vary significantly from actual professional installation pricing.

Whether you tackle this rewarding project yourself or entrust it to experienced professionals, you’re creating something special. A well-installed flagstone walkway becomes part of your home’s character—greeting guests, guiding family members, and quietly performing its job through countless seasons.

For expert installation and ongoing maintenance support throughout Bedford, Billerica, Burlington, Lexington, Reading, Stoneham, Wilmington, Winchester, and Woburn, contact AJM Grounds. Visit our Walkway Installation page to learn more about our comprehensive hardscaping services.