Why Concrete Wall Retaining Systems Are the Smart Investment for Your Property

Concrete wall retaining systems offer the best combination of durability, cost-effectiveness, and design flexibility for homeowners dealing with sloped yards, soil erosion, or the need to create usable outdoor space.

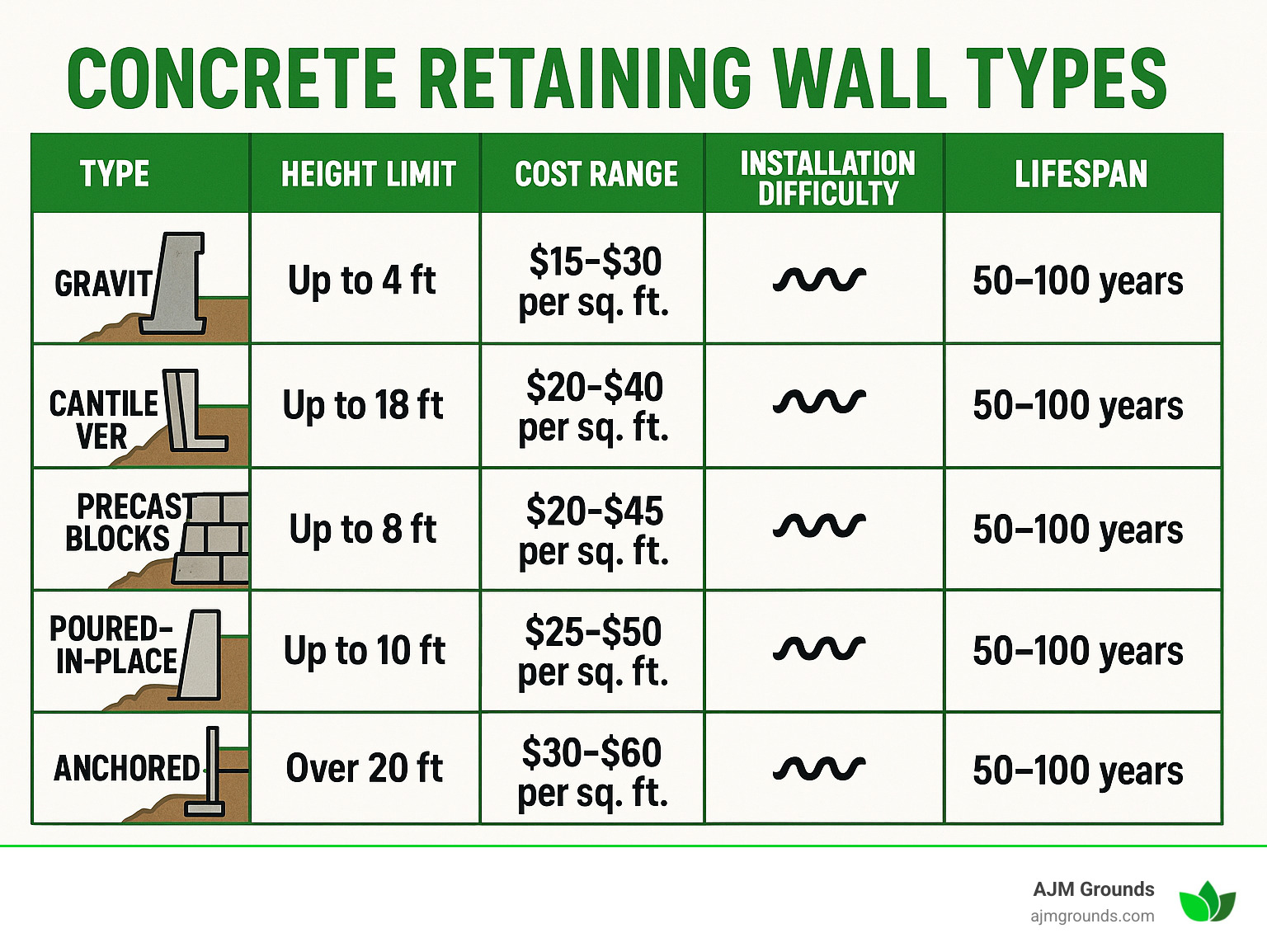

Top Concrete Retaining Wall Types:

- Gravity walls – Use weight alone to resist soil pressure (up to 4 feet)

- Cantilever walls – L-shaped design with soil-bearing heel for stability

- Precast block systems – Interlocking blocks for DIY-friendly installation

- Poured-in-place – Custom concrete forms for curves and complex shapes

- Anchored walls – Use cables or rods for maximum height capability

Key Benefits:

- Last 50-100 years with minimal maintenance

- Handle walls up to 24-36 inches without reinforcement

- Cost 20% less than comparable block systems

- Resist water, rot, and pests unlike timber alternatives

Whether you’re dealing with a sloping backyard losing soil after storms or looking to create terraced garden beds, the right concrete retaining wall can transform your property’s usability and value.

I’m John Caplis, owner of AJM Grounds LLC, and I’ve helped dozens of Woburn homeowners steer the concrete wall retaining decision over my years in the landscaping business. From simple gravity walls preventing garden erosion to complex terraced systems creating outdoor living spaces, I’ve seen how the right choice saves thousands in both upfront costs and future headaches.

Quick look at concrete wall retaining:

Concrete Wall Retaining 101: Purpose, Physics & Popular Types

A retaining wall is essentially a strong arm wrestler, constantly pushing back against tons of earth that would rather slide downhill. Without this barrier, your carefully planned landscape becomes a muddy mess, your driveway gets undermined, and that beautiful terraced garden remains just a dream.

Concrete wall retaining systems excel because they don’t rot like wood, shift like loose stone, or give up after a few tough seasons. Wet soil weighs 120 pounds per cubic foot or more, pushing against your wall 24/7.

The physics involves three forces trying to knock down your wall: soil pressure wanting to tip it forward (overturning), slide it sideways (sliding), or crush the ground underneath (bearing failure). Smart concrete wall retaining designs work with these forces instead of fighting them.

Gravity walls use pure weight – soil simply can’t budge them. Cantilever walls use L-shaped design where soil helps hold the wall down. Anchored walls use cables reaching deep into the hillside for support.

How “concrete wall retaining” structures resist lateral earth pressure

Lateral earth pressure works like a crowd pushing against a concert barrier – pressure increases with depth. Engineers calculate this at about 40 pounds per square foot for residential walls. Multiply by hundreds of square feet, and you’re dealing with thousands of pounds of force.

Concrete excels here because it can be reinforced with steel rebar for stretching forces while handling crushing forces naturally. Properly designed concrete wall retaining systems actually get more stable as soil settles and compacts.

Concrete Wall Retaining Options You’ll Meet at the Lumber Yard

Interlocking block systems are DIY-friendly, perfect for walls up to 24-36 inches without reinforcement. Blocks weigh 30-80 pounds each – heavy enough to stay put, light enough to handle.

Large-format precast blocks weigh over 1,600 pounds each, creating 5+ foot walls without geogrid reinforcement, but require machinery.

Poured concrete forms offer unlimited design flexibility with custom shapes and curves. Minimum stem thickness should be 12 inches for proper placement.

Every concrete wall needs a solid foundation with footing keys at least 2 feet deep, always below the frost line.

Comparing the Big Five Wall Systems – Pros, Cons & Best Uses

Choosing the right concrete wall retaining system can make or break your project. Here are the five main systems:

Gravity block walls handle 3-4 feet tall with easy installation difficulty. They need moderate drainage and cost $15-45 per square foot based on internet averages. Perfect for garden beds and simple slopes.

Cantilever poured walls handle 8+ feet with hard installation requiring forms and rebar. Critical drainage is essential, costing $25-75 per square foot based on internet data. Best for tall walls and custom shapes.

Anchored systems handle 15+ feet but require expert installation and high-level drainage. Costs run $40-120 per square foot based on internet averages. Use for extreme heights and tight spaces.

Precast block systems handle 2-8 feet with moderate installation difficulty and moderate drainage needs. Costs run $20-60 per square foot based on internet data. Perfect for DIY projects and straight runs.

Poured-in-place walls handle 4-12 feet with hard installation requiring high-quality drainage. Costs typically $30-90 per square foot based on internet averages. Choose for curves and integrated features.

These are average costs based on internet data, not AJM Grounds pricing.

Properly built concrete wall retaining systems last 50-100 years versus 10-20 years for timber walls.

Poured-in-Place vs Precast Block: Which “concrete wall retaining” choice pays off?

Poured-in-place concrete offers ultimate flexibility with continuous reinforcement and custom shapes. Installation is typically 20% less expensive than comparable blocks, though labor complexity is higher. No joints means no weak spots.

Precast blocks offer fast installation and DIY forgiveness. Waste factor is easier to manage, and you can build in phases or extend later without complexity.

Timber & Stone Alternatives – Why Concrete Still Wins

Timber walls last only 10-20 years before replacement. Even treated lumber faces rot, insects, and fire susceptibility. Scientific research on treated wood risks shows EPA guidelines exist for creosote-treated wood due to health concerns.

Natural stone walls are extremely labor-intensive requiring skilled masons. Costs are typically much higher than concrete, and achieving consistent lines is difficult.

Concrete eliminates these concerns – naturally resistant to water, rot, and pests. No chemical treatments needed, and it gets stronger over time.

Design Matters: Height, Thickness, Drainage & Code Compliance

Building a concrete wall retaining system requires understanding massive forces involved. Small mistakes lead to expensive failures.

Height determines everything. Walls up to 4 feet often don’t need permits with level backfill. Over 4 feet requires engineered drawings and permits. Over 8 feet needs geogrid reinforcement and specialized anchoring.

Thickness rules: footing should be one-eighth the wall height – 4-foot wall needs 6-inch base, 8-foot wall requires 12 inches. Stem should be at least 12 inches thick for proper concrete placement.

Footing depth is non-negotiable – at least 2 feet deep and below frost line. In Massachusetts, that means 4 feet deep.

Drainage design separates pros from amateurs: granular backfill, weep holes every 6-8 feet, perforated drain pipe at base, and filter fabric preventing clogging.

Avoiding the Top Causes of Failure in Concrete Wall Retaining Builds

Poor drainage kills more walls than anything else. Hydrostatic pressure from saturated soil easily overcomes well-built walls.

Shallow footings heave and crack every winter above frost line. Skipping reinforcement – steel rebar every 16 inches both ways – creates time bombs.

Surcharge loads from driveways or patios need design consideration. Frost heave combines shallow footings with poor drainage.

Permits & Engineering – When the City Says “Show Me the Calculations”

The 4-foot rule is standard, but check local codes. Permits typically require site plans, cross-sections, structural calculations from licensed engineers, and drainage plans.

Engineering process costs $500-2,000 but prevents bigger problems. Inspections at key stages cost $100-200 each but verify proper construction.

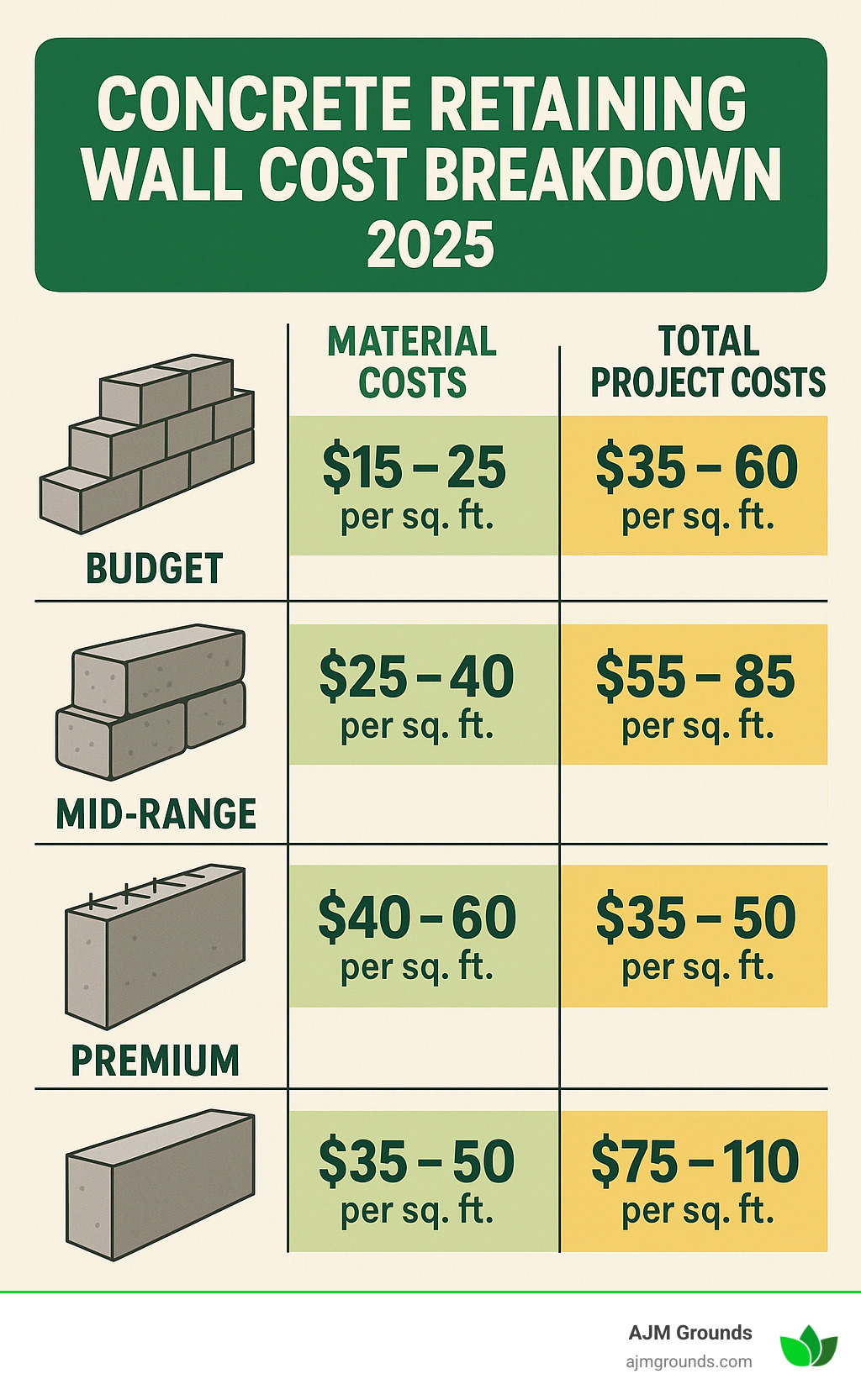

Budget Breakdown: What You’ll Pay (and Save) in 2024

Concrete wall retaining costs vary widely based on height, complexity, and site conditions:

Material costs run $20-75 per square foot based on internet pricing. Basic blocks cost $3-8 each, large-format blocks $15-35 each. Poured concrete runs $100-150 per cubic yard plus $2-5 per square foot for rebar. Drainage materials add $3-7 per linear foot.

Labor costs range $25-150 per square foot according to internet averages. Block installation: $15-40 per square foot. Poured concrete: $25-60 per square foot. Site preparation adds $5-15 per square foot.

Total project costs typically range $45-225 per square foot. Simple gravity walls: $45-125 per square foot. Cantilever poured walls: $65-175 per square foot. Complex anchored systems: $85-225 per square foot.

These are average costs based on internet data and not actual costs for AJM Grounds services.

Cost factors: Site access issues add 20-50%. Curved shapes add 15-30%. Integrated features add $500-2,000. Permits and engineering cost $500-3,000. Poor soil conditions bump costs 10-40%.

Smart Ways to Stretch Your Concrete Wall Retaining Dollars

Bundling multiple projects reduces mobilization costs and gets volume discounts. Recycling existing concrete for backfill saves $5-10 per cubic yard.

Buy 10% extra blocks to prevent costly delivery charges later. Phased builds spread costs over seasons. Handling prep work yourself saves 15-25% on labor.

DIY vs Pro: Skills, Tools & Safety Gear

Building a concrete wall retaining system yourself is doable for the right project – knowing which project is “right” prevents expensive mistakes.

You’ll need a hand tamper or plate compactor for soil compaction in 6-inch lifts. A laser level for walls longer than 20 feet. Block splitter or concrete saw for cuts. PPE is non-negotiable – concrete dust destroys lungs.

Call 811 before digging – it’s free and prevents utility strikes. First-course leveling determines project success – spend a full day getting foundation perfect.

When a Weekend Warrior Can Handle “concrete wall retaining” – and When to Call a Pro

Gravity walls under 3 feet tall with straight runs and simple drainage are perfect DIY territory. Level backfill and good site access make huge differences.

Call professionals for: Complex curves, tall walls over 4 feet, municipal inspections, sloped backfill, or surcharge loads like driveways.

Most homeowners can successfully build simple concrete wall retaining systems up to 3 feet tall. Beyond that, professional expertise usually makes investment worthwhile.

Trending Looks & Finishes for 2024 Landscapes

Concrete wall retaining systems no longer need to look industrial. Today’s design possibilities are exciting.

Board-form finish for poured concrete creates wood-grain texture giving timber warmth without maintenance. Stone-texture form liners make concrete look like natural fieldstone at fraction of stone cost.

Integral coloring goes through entire concrete – chips won’t show, color gets richer over time. Popular: earth tones, charcoal grays, subtle blues.

Mixed-material designs pair concrete with wood caps, steel accents, or glass panels. Terraced systems replace single tall walls with multiple smaller walls and planted areas.

Integrated lighting with LED strips in capstones creates uplighting. Living wall features include built-in planters as part of structure.

Sustainable Spin: Permeable Backfills & Low-carbon Mixes

Supplementary cementitious materials like fly ash replace up to 30% of cement, reducing emissions while improving strength. Recycled aggregate from demolition performs as well as virgin materials.

Permeable backfill systems turn walls into stormwater management tools. Rain garden integration directs water into planted filtration areas. Native plant integration supports local ecosystems while providing erosion control.

Frequently Asked Questions about Concrete Retaining Walls

How many blocks do I need for my wall?

Calculate total wall area (length × height). Most blocks cover 1-2 square feet each. Always order 10% extra blocks for cuts, repairs, and damaged blocks. A 50-foot × 3-foot wall needs blocks for 55 feet instead of 50.

Do I always need geogrid reinforcement?

Many concrete wall retaining block systems handle 24-36 inches without geogrid. Heavy-duty systems go up to 5 feet. Need depends on height, soil type, and surcharge loads. Check manufacturer specifications – every system has detailed requirements.

What’s the minimum drainage I can get away with?

There’s no “minimum” drainage – either it’s adequate or your wall fails. Proper drainage isn’t optional. You need: granular backfill, weep holes every 6-8 feet, perforated drain pipe at base, filter fabric. Drainage costs under 15% of project but determines 10-year vs 50-year lifespan.

Conclusion

Building a concrete wall retaining system transforms your property for decades. This isn’t just about holding back dirt – it’s creating lasting value, preventing erosion, and gaining usable outdoor space.

After helping homeowners throughout Woburn, Bedford, Billerica, Burlington, Lexington, Reading, Stoneham, Wilmington, and Winchester, the biggest mistake is thinking all retaining walls are the same.

Gravity block walls work for simple garden beds under 4 feet. Poured cantilever walls handle height, curves, and custom features. Anchored systems tackle extreme situations.

Spending more upfront on proper engineering and drainage saves thousands later. Concrete wall retaining systems offer best longevity – 50-100 years versus 10-15 years for timber.

Your situation drives everything: garden bed walls have different requirements than driveway-supporting walls. Height determines permits, site conditions affect drainage, timeline influences block versus poured concrete choice.

The upfront investment pays for itself through eliminated maintenance, increased property value, and peace of mind during storms. You get functional, attractive outdoor space that works with your landscape.

Whether DIY or professional installation: drainage isn’t optional, footings can’t be shallow, permits exist for good reasons. Get fundamentals right, and your concrete wall retaining system serves your family for generations.

More info about retaining wall builders