Understanding Concrete Block walls

Concrete block wall installation is a construction process that involves laying concrete masonry blocks (CMUs) to create durable, functional walls for various landscaping and structural purposes. Whether you’re building a retaling wall to control erosion, creating privacy barriers, or constructing garden walls, understanding the basics can help you make informed decisions about your project.

Here’s what concrete block wall installation involves:

- Planning and permits – Checking local codes and obtaining permits for walls over 36 inches

- Site preparation – Excavating and creating a level foundation

- Foundation work – Installing a gravel base or concrete footing

- Block laying – Setting blocks in courses with proper alignment and spacing

- Reinforcement – Adding rebar and drainage systems as needed

- Finishing – Installing capstones and completing the wall

Concrete block walls offer several advantages that make them popular for homeowners. They’re incredibly durable – a well-constructed block wall can last up to 80 years with proper maintenance. They also provide excellent soundproofing and require minimal upkeep compared to wood fencing or other alternatives.

The most common types include standard cinder blocks (measuring 16×8×8 inches), interlocking blocks with built-in alignment systems, and decorative split-faced blocks for improved aesthetics. Each type serves different purposes, from basic utility walls to attractive landscape features.

As John Caplis, owner of AJM Grounds LLC, I’ve completed numerous concrete block wall installation projects throughout Woburn, Massachusetts, helping homeowners create lasting outdoor solutions. My experience has shown that proper planning and execution are crucial for walls that stand the test of time.

Easy concrete block wall installation glossary:

Planning Your Project: Before You Break Ground

The difference between a concrete block wall installation that lasts decades and one that fails within a few years often comes down to what happens before you even touch a single block. Trust me, I’ve seen too many weekend warriors skip the planning phase only to end up with a wobbly wall that needs complete reconstruction.

Your first decision centers on what you’re actually building. A retaining wall that needs to hold back tons of soil requires completely different planning than a decorative garden wall. Retaining walls demand careful consideration of soil pressure, water drainage, and structural integrity. Privacy walls focus more on height and appearance, while garden walls might prioritize aesthetics over heavy-duty strength.

Wall height becomes crucial because it determines whether you need permits. Most areas require permits for walls over 36 inches tall, but the rules vary significantly by location. In Chicago, you’ll need permits for retaining walls over 4 feet, while Los Angeles requires permits for any retaining wall that supports a slope. Don’t assume – check with your local building department first.

Before you start digging, calling 811 is absolutely essential. This free utility marking service prevents you from accidentally hitting gas lines, water pipes, or electrical cables. I’ve seen homeowners face thousands in repair costs because they skipped this simple step. The service typically takes 2-3 business days, so plan accordingly.

For complex projects or walls over 4 feet, consulting professionals who understand block retaining wall design can save you from costly mistakes and ensure your wall meets all structural requirements.

Essential Tools and Materials

Having the right tools makes concrete block wall installation significantly easier and more accurate. You’ll need a shovel for excavation work, a quality level in both 2-foot and 4-foot lengths, and a reliable measuring tape for layout work. Mason’s line and stakes help you maintain straight, level courses, while a rubber mallet lets you adjust blocks without damaging them.

For mortar work, you’ll need a mason’s trowel, and a wheelbarrow makes moving materials much easier. A hand tamper is essential for compacting your base properly, and either a masonry saw or chisel handles any block cutting needs.

Material-wise, you’ll need concrete blocks (calculated based on your wall dimensions), ¾-inch crushed stone for the base, sand for leveling, and either mortar or masonry adhesive. Depending on your wall’s height and purpose, you might also need rebar for reinforcement, perforated drain pipe, landscape fabric, backfill gravel, and capstones with concrete adhesive.

How to Estimate Material Quantities

Getting your material calculations right prevents frustrating delays and reduces waste. Start by calculating your wall’s total square footage – simply multiply length times height. Each standard concrete block covers 1.125 square feet, so divide your wall area by this number to get your block count.

Here’s where experience pays off: always add 5-10% extra blocks for breakage, cutting waste, and future repairs. For a 20-foot long by 4-foot high wall (80 square feet), you’d need about 71 blocks, but order 78 to account for that extra 10%.

Base materials require careful calculation too. Plan for at least 6 inches of compacted gravel base extending the full width of your trench. Backfill gravel should extend 12-18 inches behind the wall. One cubic yard of sand typically covers about 150 square feet at 2 inches deep.

Mortar needs are straightforward – one 80-pound bag typically handles 12-14 blocks. For our 78-block example, you’d need about 6 bags. Always check manufacturer guidelines since different block types can have varying coverage rates.

It’s better to have slightly too much material than to stop work halfway through because you ran short. Most suppliers will take back unopened bags, but your project timeline won’t recover from material delays.

The Complete Concrete Block Wall Installation Process

Step 1: Site Preparation and Excavation

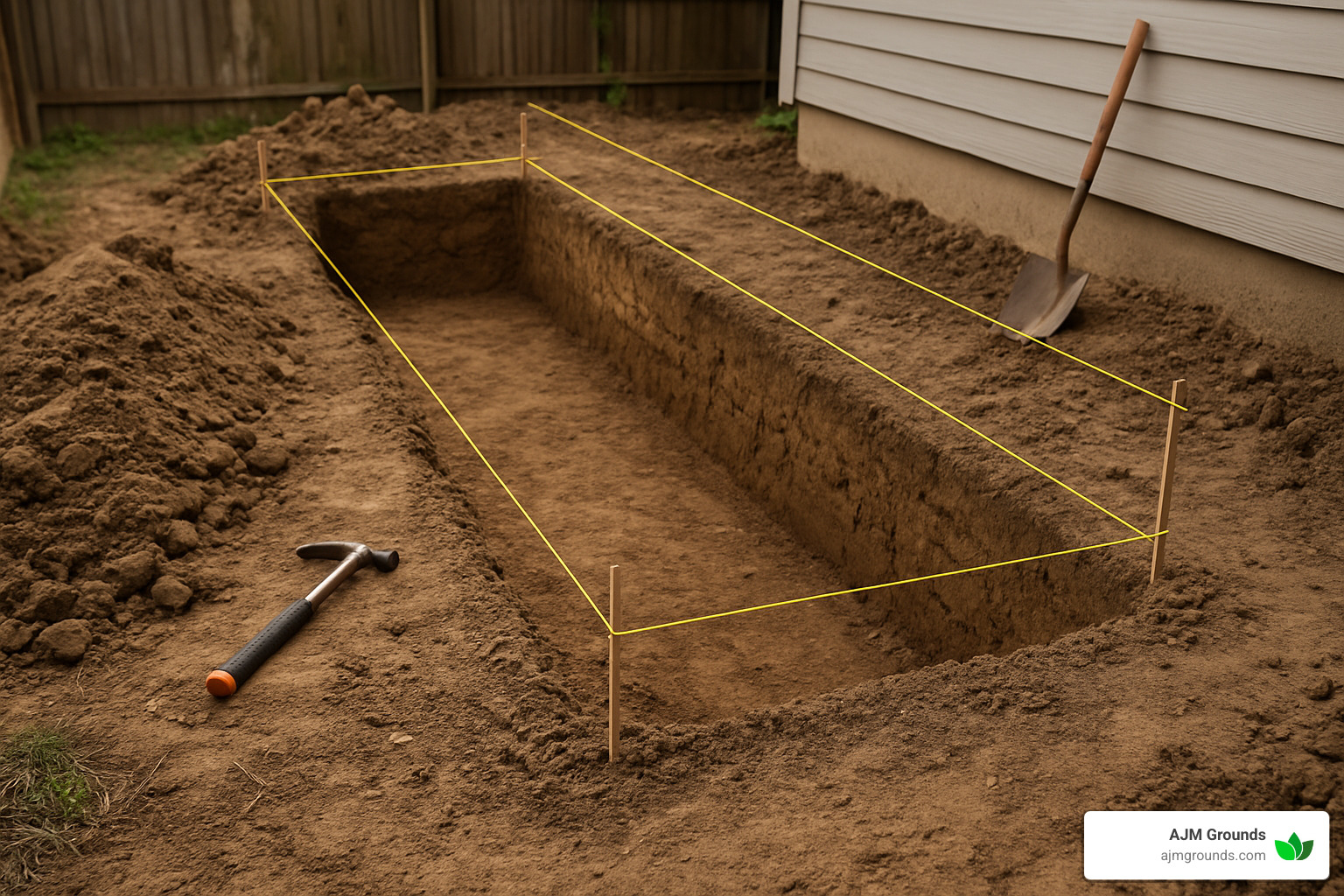

Stake out the wall footprint, run mason’s line for reference, then paint your dig lines. Excavate a trench twice the block width (16 in. for an 8 in. block) and deep enough for 6 in. of gravel, half a block below grade, and below the frost line (about 48 in. in Massachusetts). Remove roots and loose soil, then compact the sub-base.

Step 2: Creating the Foundation and Base Course

For garden or low walls, a 6-in. compacted gravel footing is usually sufficient. Walls over 4 ft or load-bearing structures need a poured concrete footing at least twice the block width. Compact gravel in 2-in. lifts, add a 1-in. sand leveling pad, and let concrete cure seven days before setting blocks. For more detail, see our concrete retaining wall builders guide.

Step 3: Laying the First and Subsequent Courses

Dry-fit the first course, then set each block into a 1-in. mortar bed (or masonry adhesive for shorter decorative walls). Keep 3/8-in. joints, tap blocks with a rubber mallet, and check level in both directions. Start the second course with a half-block to create a running bond. Repeat the level-check every few blocks or visit our how to install a block retaining wall resource for deeper guidance.

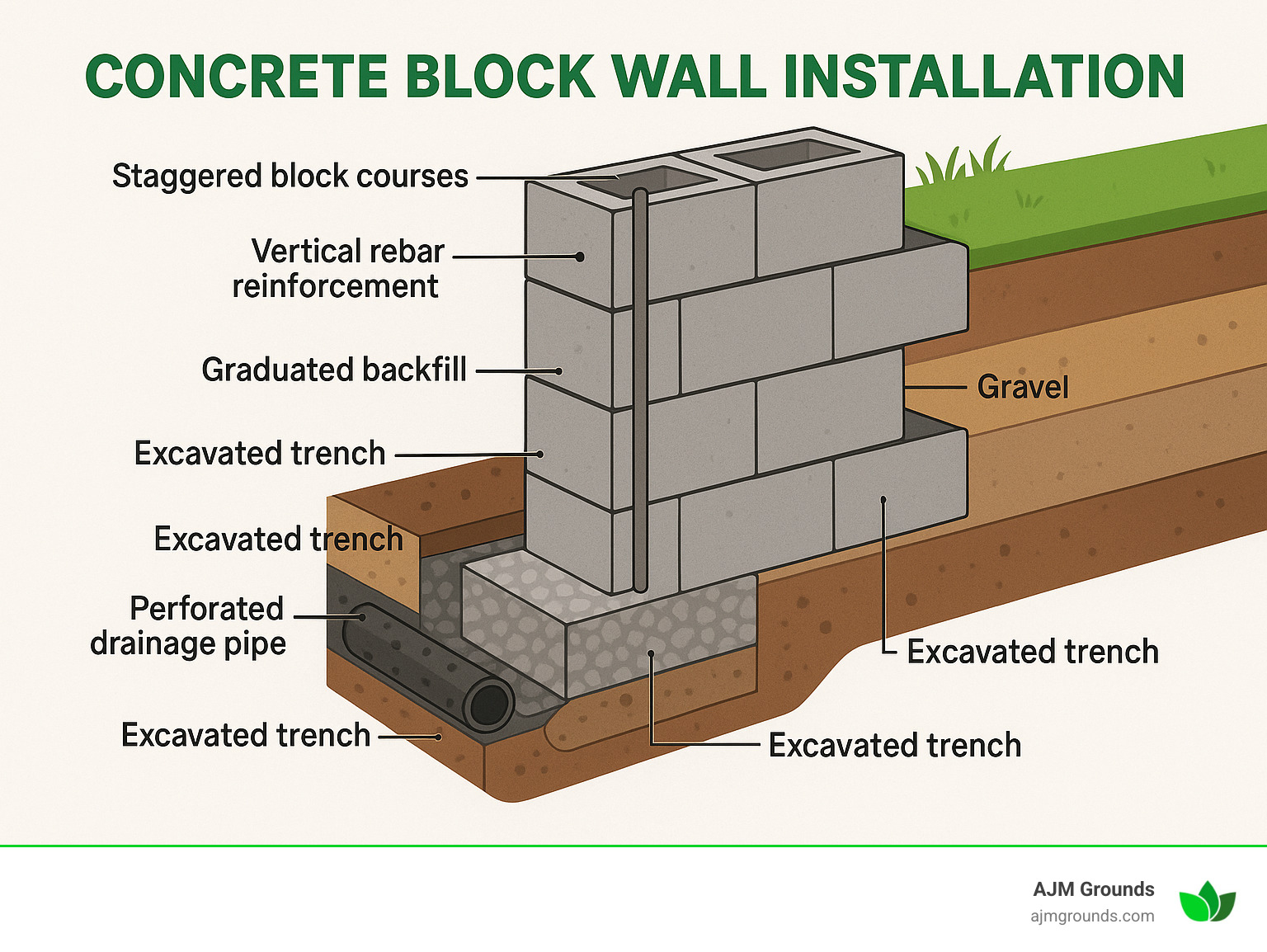

Step 4: Adding Reinforcement, Drainage, and Backfill

Place #4 vertical rebar every 24 in. in walls over 4 ft. Lay a perforated drainpipe at the footing with 1 % slope, wrap it in landscape fabric, and backfill 12–18 in. behind the wall with clear gravel in 6–8 in. lifts, compacting each layer lightly.

Step 5: Finishing the Wall

Cut blocks with a masonry saw or chisel as required. Clean the top course, apply masonry adhesive, and place capstones. Tool mortar joints once they reach thumb-print hardness to form neat, water-shedding concave joints.

Key Considerations for a Lasting Wall

Mortar vs. Masonry Adhesive: Which to Choose?

Traditional mortar delivers the strongest bond and remains the best option for structural or tall walls. It takes longer to mix and cure (up to 28 days for full strength) but offers best durability. Cartridge-style masonry adhesive comes ready to use and cures in about a week, making it handy for low, decorative walls under 3 ft. If you are unsure, consult our cinder block wall installation team before buying materials.

Essential Safety Precautions

Moving 80-lb blocks and mixing cement can be tough on the body. Wear heavy-duty gloves, safety glasses, and a dust mask. Lift with your legs, keep tools sharp, maintain a tidy jobsite, and never work alone on large lifts or near open trenches.

DIY vs. Hiring a Professional

Small garden walls under 4 ft can be satisfying DIY projects if you have time, patience, and the right tools. Anything taller, load-bearing, curved, or subject to permits is usually faster and less risky when handled by a pro. Our crew serves Woburn, Burlington, Reading, and nearby towns with equipment, code knowledge, and warranties. Learn more about our retaining wall construction services.

Frequently Asked Questions about Concrete Block Wall Installation

How deep should the footing be for a concrete block wall?

Getting the footing depth right is crucial for a stable concrete block wall installation. Think of it as the foundation that keeps your entire wall from becoming an expensive pile of rubble.

The footing width should be at least twice your block width. For standard 8-inch blocks, you’ll need a minimum 16-inch wide footing. This gives your wall the broad base it needs to distribute weight properly.

Depth calculations get a bit more complex because you’re dealing with multiple layers. Your trench needs to accommodate the footing or base extending below your local frost line to prevent heaving, plus a minimum 6-inch compacted gravel base, plus burying approximately half of your first block course below final grade, plus about 1 inch for a sand leveling pad.

Here in Massachusetts, where the frost line typically extends 48 inches below ground, your total excavation depth could easily reach 54 inches or more. It might seem like a lot of digging, but it’s the difference between a wall that lasts decades and one that shifts after the first hard winter.

How do you keep a block wall from falling over?

Nobody wants to watch their carefully built wall become a domino display, so let’s talk about the key factors that keep your wall standing strong.

A solid, level foundation is your first line of defense. Any settling or heaving will compromise the entire wall, which is why we emphasize proper foundation preparation. Think of it as the anchor that everything else depends on.

Proper drainage might be the most underestimated factor. Hydrostatic pressure from water buildup behind the wall is actually the leading cause of wall failure. Install perforated drain pipes and use clear gravel backfill to give water somewhere to go instead of pushing against your wall.

Staggered joints using a running bond pattern distribute loads more evenly across the wall. Each course should be offset by half a block length, preventing the wall from separating along vertical lines like a zipper coming apart.

For retaining walls, back-setting each course by approximately 3/4 inch creates a slight backward lean that helps the wall resist soil pressure. It’s like leaning into the wind – the wall naturally braces itself against the forces trying to push it over.

Finally, reinforcement with vertical rebar placed every 24 inches and filled with concrete or mortar provides additional strength for walls over 4 feet tall or those bearing structural loads.

Can I build a concrete block wall without mortar?

Absolutely! There are two proven methods for building concrete block walls without traditional mortar, and both can create strong, durable walls.

The masonry adhesive method uses construction adhesive designed specifically for masonry applications. It’s particularly convenient for shorter, non-structural walls and cures faster than traditional mortar. While it may not provide the same long-term strength as mortar, it’s perfect for garden walls and decorative applications.

The dry-stack method with surface bonding cement involves stacking blocks without any mortar between them, then applying a surface bonding cement to both sides of the wall. This creates both structural strength and a finished, textured appearance in one step.

Surface bonding cement typically reaches 5,000 psi strength in 28 days and can be tinted with liquid colorants for aesthetic appeal. The dry-stack method is often easier for DIY builders because it eliminates the challenge of maintaining perfectly level mortar joints throughout the entire wall.

Both methods require the same careful attention to foundation preparation, drainage, and reinforcement as traditional mortar construction. The foundation and drainage are still the most critical elements for long-term success, regardless of which bonding method you choose.

Conclusion: Your Next Steps for a Perfect Wall

Building a concrete block wall installation is like creating a lasting legacy in your landscape. Each step we’ve covered – from that first careful excavation to placing the final capstone – works together to create something that will serve your family for generations.

The beauty of concrete block walls lies in their simplicity and strength. When you follow the fundamentals we’ve discussed, you’re not just stacking blocks – you’re building a foundation for your outdoor dreams. That solid, level foundation below the frost line becomes the anchor. The proper drainage system protects your investment from water damage. Those staggered joints create the strength that keeps everything standing tall.

Whether you’re tackling a weekend garden wall project or planning a major retaining wall, these principles never change. The materials may vary, the height might differ, but the core requirements remain constant. It’s this consistency that makes concrete block construction so reliable.

A well-executed concrete block wall offers incredible value that extends far beyond its initial cost. We’re talking about durability that spans up to 80 years, functionality that solves real problems, and aesthetic appeal that improves your property value. With just occasional cleaning and joint inspection, your wall will continue looking great and performing flawlessly.

For homeowners in Woburn, Burlington, Reading, Winchester, and surrounding Massachusetts communities, some projects naturally call for professional expertise. Complex retaining walls, structures requiring permits, or installations in challenging soil conditions benefit from experienced hands who understand local codes and New England’s unique construction challenges.

At AJM Grounds, we’ve walked alongside countless homeowners through their concrete block wall projects. We understand that every wall tells a story – whether it’s creating a safe play area for children, solving a persistent drainage problem, or simply adding that perfect finishing touch to your landscape design.

Our team brings more than just technical expertise to your project. We understand local soil conditions, steer permit requirements seamlessly, and ensure every wall meets the highest structural standards. From initial design conversations to final cleanup, we handle the details so you can focus on enjoying the results.

If you’re ready to move forward with professional installation, or if you’d like to discuss whether your project might benefit from expert guidance, we’re here to help. Every great wall starts with a conversation about your goals, your space, and your vision.

To discuss your project and receive a professional assessment, explore our retaining wall construction services or reach out directly. We’re committed to helping you create outdoor spaces that combine functionality, beauty, and the kind of lasting value that makes you smile every time you see it.