What is a Concrete Block Retaining Wall?

Concrete block retaining wall construction is the process of building a structural barrier with interlocking concrete units to hold back soil. These walls prevent erosion, create level planting areas, and turn steep, unusable terrain into functional outdoor space.

Quick Construction Overview:

- Purpose: Hold back soil, prevent erosion, create usable space

- Height Range: DIY walls typically 15-36 inches tall

- Key Components: Concrete blocks, compacted base, drainage system, backfill gravel

- Essential Steps: Site preparation → foundation → first course → stacking → drainage → finishing

- Timeline: Most DIY walls can be completed in 1-2 weekends

Retaining walls are critical landscape features. As one contractor noted, “When a concrete wall fails, it’s over. You have to build a new wall from scratch.” This guide will teach you proper construction techniques to avoid that costly mistake.

The physics is simple: soil weighs over 100 pounds per cubic foot and constantly pushes outward. Without proper construction and adequate drainage, even the strongest wall will eventually fail. With the right approach, a well-built concrete block wall can last 50-100 years.

As John Caplis from AJM Grounds, I’ve guided many homeowners in the Woburn area through concrete block retaining wall construction projects. My experience has shown that success comes from understanding the technical requirements and practical steps for a manageable DIY project.

Terms related to concrete block retaining wall construction:

- concrete retaining wall installation

- paver base for retaining wall

- installing cap stone on retaining wall

Before You Build: Planning, Preparation, and Materials

This section covers the critical groundwork needed before the first block is laid, ensuring your project is safe, compliant, and set up for success.

Essential Planning and Regulatory Steps

Proper planning for your concrete block retaining wall construction project saves you from major headaches and dangerous situations.

Your first call should be to 811. This free service locates underground utility lines, a crucial step to avoid a dangerous and expensive accident.

Next, you must address local building codes and permit requirements. Rules vary significantly across Massachusetts towns like Bedford, Billerica, Burlington, and Woburn. Most towns require building permits for walls over 4 feet high, but some jurisdictions require engineered designs for walls over 24 inches. Your Homeowners Association (HOA) may also have rules about wall height, materials, and placement near property lines. A quick call to your local building department can prevent having to tear down a finished wall.

Finally, perform a site assessment and evaluate soil conditions. Clay soil retains water while sandy soil drains quickly; this difference will affect your drainage strategy. Understanding your site is key. Compliance with safety standards isn’t just red tape—it ensures your wall will last for decades.

If you need help with the planning phase, our team can assist with Block Retaining Wall Design.

Essential Tools and Materials for Concrete Block Retaining Wall Construction

Having all your tools and materials ready beforehand will make the project run smoothly.

Essential Tools You’ll Need:

- Shovel and wheelbarrow for excavation.

- Tape measure for accuracy.

- 4-foot level and torpedo level to ensure blocks are perfectly set.

- Rubber mallet for positioning blocks without damage.

- Hand tamper to compact base materials (rent a plate compactor for larger projects).

- Mason’s line and stakes to create a straight, level guide.

- Safety gear: safety glasses, gloves, and hearing protection are mandatory.

- Caulk gun for masonry adhesive.

- Block chisel and hammer for cutting blocks.

Materials That Make or Break Your Project:

- Concrete blocks: The star of the show.

- Paver base or compactable gravel: Forms your foundation; don’t cut corners here.

- Crushed gravel for backfill: Provides essential drainage.

- Landscape fabric: Prevents soil from clogging your drainage system.

- Perforated drain pipe: Prevents hydrostatic pressure buildup.

- Masonry adhesive: Secures capstones.

- Capstones: The professional finishing touch.

Choosing the Right Concrete Blocks

Picking the right blocks is critical for your concrete block retaining wall construction project.

Interlocking blocks (also called Segmental Retaining Wall or SRW blocks) are best for DIY projects. They have built-in lips or pinned systems that lock each course to the one below, creating a natural setback and eliminating the need for mortar on shorter walls. They are forgiving and can handle walls up to 36 inches high.

Gravity-held blocks rely on weight for stability and are suitable for low borders. For aesthetics, split-faced blocks offer a natural stone texture, while tumbled blocks have a weathered, aged look.

Modern interlocking systems are engineered for DIY-friendly design, giving you professional results without needing a masonry degree. For most homeowners building walls under 3 feet, these blocks offer the perfect balance of structural integrity, ease of installation, and appearance.

If you’re considering Installing Landscape Blocks but want professional guidance on block selection, we can help.

Your Step-by-Step Guide to Concrete Block Retaining Wall Construction

Follow these detailed steps to build a wall that is both strong and beautiful. Proper technique at each stage is key to a long-lasting structure.

Step 1: Site Preparation and Excavation

Proper excavation is the first step toward a wall that will stand for decades.

Start by marking the layout of your wall using stakes and a mason’s line for straight walls, or a garden hose for curves. Precision from the start is key.

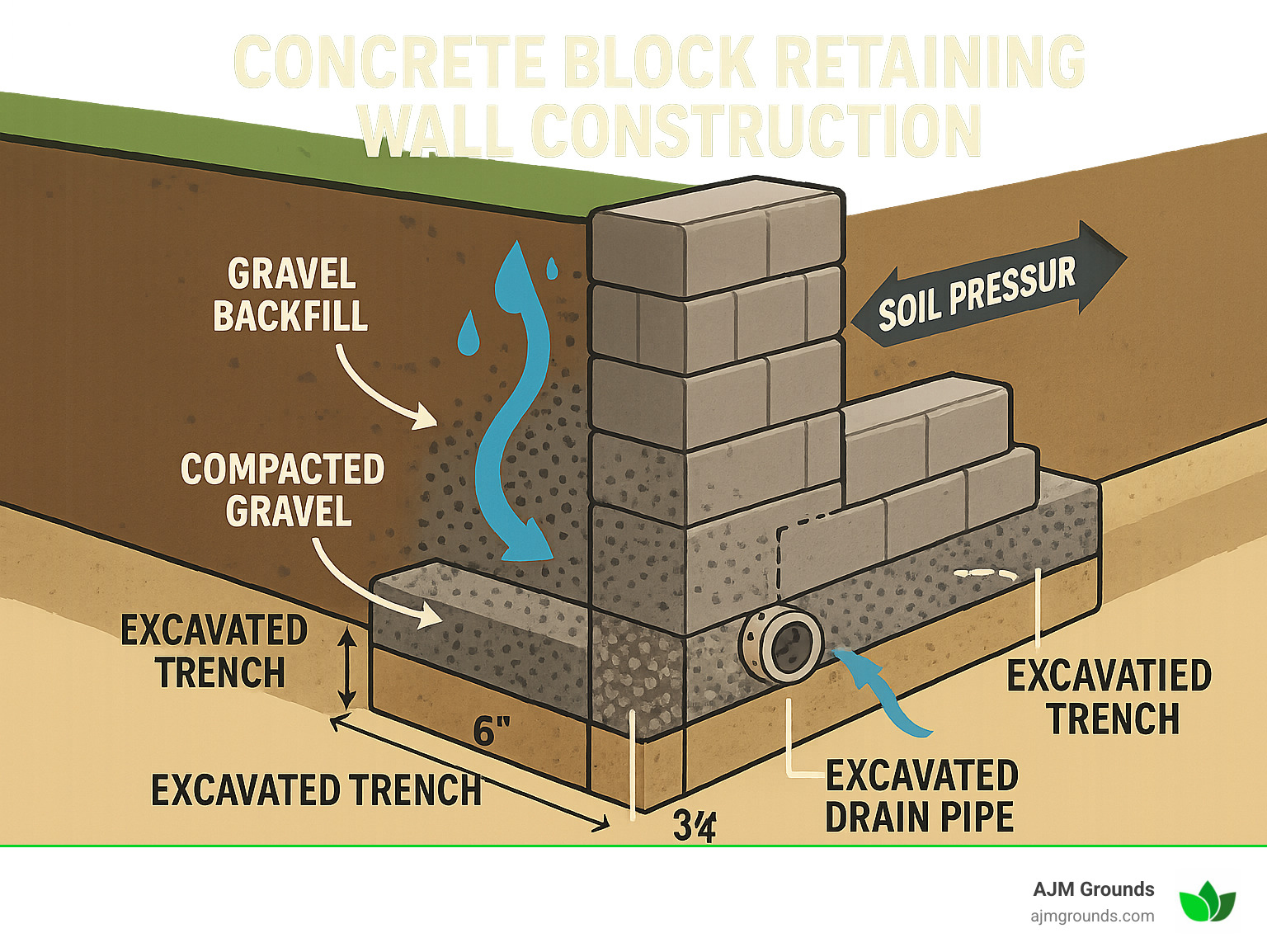

When digging the trench, aim for a width about twice that of your block (typically 12 inches) to allow room to work. For depth, dig 4 to 6 inches for your base material, plus enough to bury about half of your first course of blocks. For a 6-inch tall block, your total trench depth would be 7 to 9 inches. This buried first course prevents the wall from sliding forward.

Once dug, level the trench bottom with a shovel and torpedo level. Then, compact the soil at the bottom with a hand tamper to create a solid foundation.

For more details, see our guide on How To Install A Block Retaining Wall.

Step 2: Building a Solid Foundation

This compacted gravel base is what separates amateur walls from professional-grade construction.

Spread 3 to 6 inches of paver base or compactable gravel (often called “Class V”) evenly in the trench. This engineered mix of stone and sand locks together when compacted.

Compacting is everything at this stage. Use a hand tamper or a rented plate compactor, making multiple passes until the base is firm enough that you can barely make an indentation with your heel.

A pro tip for concrete block retaining wall construction: after compacting, screed a thin layer of sand (about 1 inch) over the top. This allows for fine-tuning the level of the first course. The gravel provides strength and drainage, while the sand allows for precision.

For more on this process, visit our Retaining Wall Construction page.

Step 3: Laying the First Course

Your first course is the most critical part of concrete block retaining wall construction. Get it right, and the rest of the project will go smoothly.

Start with your first block at the lowest point of the wall. If your blocks have a rear lip or flange for interlocking, you must remove it from the first course blocks using a hammer and masonry chisel (wear safety glasses).

Place the first block and check it with your torpedo level both front-to-back and side-to-side. Use a rubber mallet to gently tap the block into a perfectly level position.

Continue laying blocks, using a 4-foot level to check across multiple blocks at once. Your first course should be about halfway buried after backfilling, which anchors the wall against soil pressure. For visual instructions, see our Block Wall Installation guide.

Step 4: Stacking Subsequent Courses and Backfilling

With the first course set, the rest of the process is a rhythm of stacking and backfilling.

Stagger your joints in a running bond pattern for strength. You will need to cut blocks in half for the ends of alternating courses. Score the block with a chisel, then strike it firmly with a hammer. Always wear safety gear when cutting blocks.

Before laying each new block, sweep the previous course clean. Debris can throw off alignment. Most interlocking systems are designed to back-set each course about 3/4 inch, creating a slight backward lean that adds strength.

After every one or two courses, backfill with crushed gravel. If installing a perforated drain pipe (recommended for walls over 2 feet), place it at the base behind the first course, surrounded by gravel.

Compact the backfill in thin lifts (3-4 inches at a time) to prevent settling. Continue this process—lay blocks, backfill, compact—until you reach your desired height. For more guidance, visit our Paver Retaining Wall Installation page.

Ensuring Longevity: Drainage, Reinforcement, and Failure Prevention

A retaining wall is only as good as its ability to manage water and pressure. This section details the most critical aspects of building a wall that will stand the test of time.

The Critical Role of Proper Drainage

Drainage is the single most important factor in concrete block retaining wall construction. A wall without proper drainage can be destroyed by a single heavy rainstorm.

When water gets trapped behind a wall, the saturated soil creates immense hydrostatic pressure, which can cause even the strongest wall to fail. The solution is to create a path for water to escape.

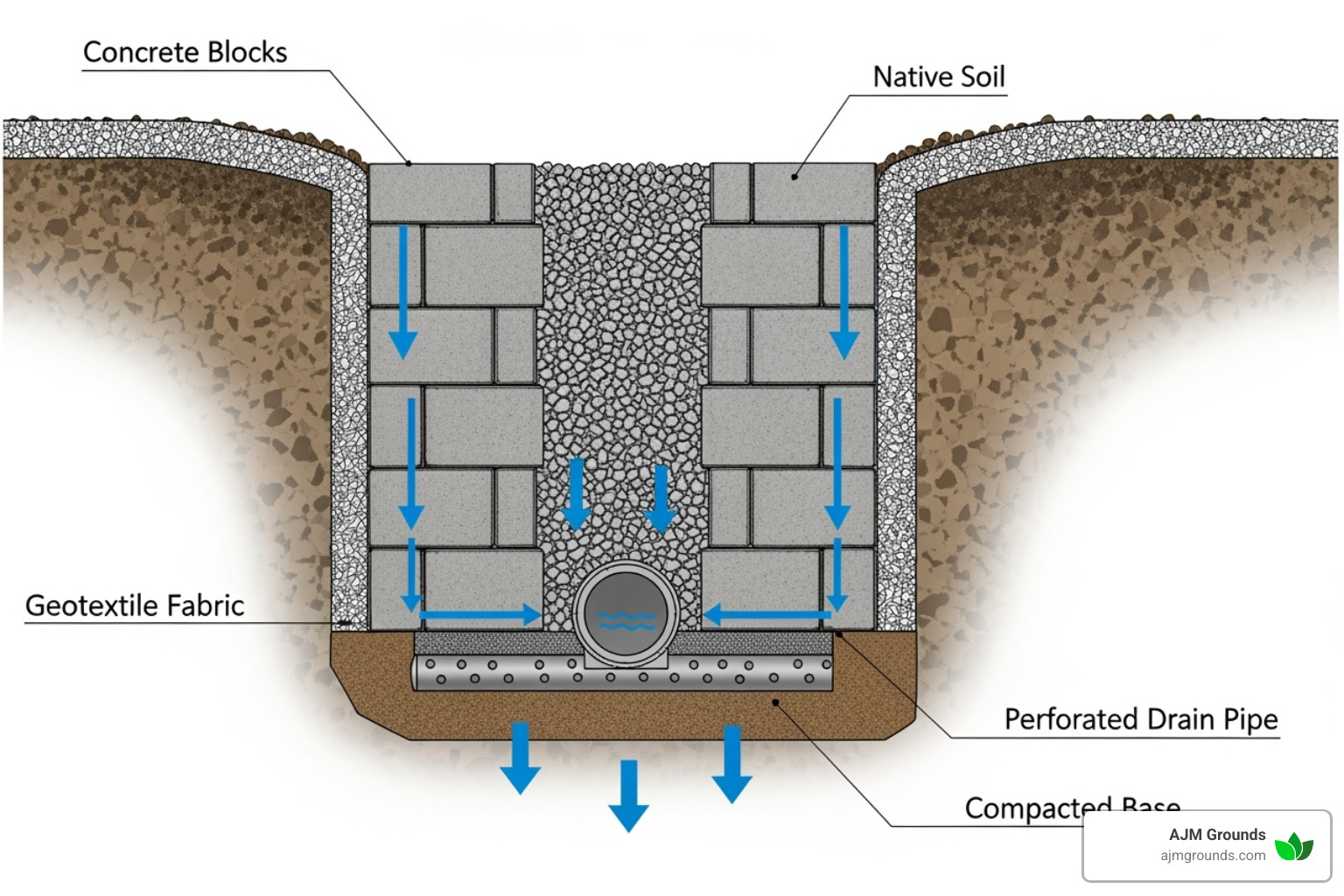

Your perforated drain pipe is the core of this system. Install a 4-inch corrugated drain pipe with holes facing down at the base of the wall, just behind the first course. This gives water a clear exit path.

The drain pipe works with your gravel backfill. A layer of crushed gravel at least 12 inches wide behind the blocks creates a fast-draining zone, allowing water to flow freely down to the pipe.

Use landscape fabric to line the excavation before adding gravel, then fold it over the top of the gravel before adding soil. This porous material prevents soil from clogging the gravel, keeping your drainage system effective for decades.

For walls in areas with heavy water flow, consider adding weep holes in the bottom course to let water escape through the wall face. Always grade the area so surface water flows away from the wall. A comprehensive drainage system works with nature, not against it. For more technical details, see this cross-section diagram and our guide on Concrete Wall Retaining.

Common Failures in Concrete Block Retaining Wall Construction and How to Prevent Them

Most wall failures are preventable if you know what to look for.

- Poor drainage is the number one cause of failure, leading to leaning or bulging. The fix is a comprehensive drainage system.

- Inadequate foundation (trench not deep/wide enough, poor compaction) causes uneven settling and cracking. A 4-6 inch compacted gravel base is essential.

- Improper backfill like topsoil or clay holds moisture. Always use crushed gravel for the drainage zone behind the blocks.

- Exceeding height limits for your chosen block system can lead to failure. DIY interlocking block walls are typically limited to 3 feet. For taller slopes, build multiple terraced walls.

- Insufficient setback (building a perfectly vertical wall) ignores soil pressure. Most interlocking systems have a built-in setback that uses the backfill’s weight for support.

- Poor compaction of the base, gravel, and soil layers leads to settling and uneven pressure over time. Compact all materials in thin lifts.

Watch for warning signs like leaning, bulging, cracks, separation at joints, or water seepage. Early detection can sometimes allow for repairs, but often a complete rebuild is necessary. If you have a problem wall, our team offers Retaining Wall Repairs.

Mortar vs. Masonry Adhesive

For securing blocks, you can choose between traditional mortar and modern masonry adhesive.

Mortar creates a strong, permanent bond and is required for taller structural walls or traditional CMUs, especially if local codes mandate it. However, it requires skill to apply and takes up to 28 days to cure.

Masonry adhesive is a DIY-friendly option that comes in a caulk tube and cures in 24 hours to a week. It provides sufficient strength for most interlocking block walls under 3 feet, especially for securing capstones. Interlocking systems rely primarily on their design, weight, and proper backfill for stability, with adhesive acting as extra security.

| Criteria | Mortar | Masonry Adhesive |

|---|---|---|

| Strength | Stronger, more permanent bond | Sufficient for most DIY walls, less permanent |

| Best Use Case | Taller/structural walls; traditional CMU blocks that require filled cores and rebar; professional installations | Shorter/non-structural walls (under 3ft); capstones; quick fixes; DIY-friendly interlocking blocks |

| Curing Time | Up to 28 days for full cure | 24 hours to 7 days |

| Application Ease | More difficult; requires mixing, troweling skills | Easy (caulk gun application) |

For most DIY projects, masonry adhesive offers the best balance of strength and convenience. Regardless of your choice, the wall’s success depends on a solid foundation and proper drainage.

Design, Finishing Touches, and Project Costs

You’ve done the heavy lifting, literally! Now it’s time to put the finishing touches on your wall and understand the investment you’ve made.

Finishing Your Wall with Capstones and Landscaping

Capstones provide a clean, finished look and protect the top course of blocks from weather.

To install capstones, apply generous beads of construction adhesive to the top of your final course of blocks. Position the capstones with a slight overhang of 1 to 1½ inches over the wall’s face. This creates a pleasing shadow line and helps shed rainwater away from the wall, protecting it from freeze-thaw damage. Press each capstone firmly into the adhesive and check for levelness. For detailed instructions, see our guide on Installing Cap Stone On Retaining Wall.

Once capstones are secure, complete the backfill. Fold the excess landscape fabric over the gravel, then add quality topsoil on top. This separates your drainage gravel from the planting soil.

For landscaping integration, consider low-maintenance perennials or ornamental grasses with shallow root systems. You can also improve your design by integrating steps for access, building gentle curves for a natural look, or adding landscape lighting for nighttime visual impact.

Estimating Your Project Cost

DIY concrete block retaining wall construction offers significant cost savings. Understanding the potential investment helps you budget effectively.

Based on internet data from sources like Angi, the average cost to rebuild or replace a retaining wall is just over $6,000. However, this doesn’t reflect the substantial labor savings from a DIY project.

Professional installation costs for concrete block retaining walls typically range from $35 to over $150 per square foot. This wide range reflects factors like block type, wall height, design complexity, soil conditions, and local material prices. Please note, these are average costs based on internet data and not actual costs for AJM Grounds.

By choosing the DIY route, you can save $15 to $50 per square foot in labor costs alone. For a 90-square-foot wall, that’s a potential savings of $1,350 to $4,500.

Investing in proper materials upfront—quality blocks, adequate gravel, and proper drainage components—saves money in the long run. A well-built wall can last 50-100 years, while a cheap one may fail within a decade. Your investment adds lasting value and functionality to your property.

Frequently Asked Questions about Concrete Block Retaining Walls

Here are answers to the most common questions about concrete block retaining wall construction.

How high can I build a DIY concrete block retaining wall?

Interlocking blocks are generally suitable for DIY walls up to 36 inches high. Taller walls face exponentially more soil pressure and typically require professional engineering, geogrid reinforcement (a mesh extending into the soil), and a building permit.

Always check your local codes first. Some jurisdictions have height limits as low as 24 inches before requiring permits and professional plans. Requirements in our service areas around Woburn, Bedford, and Billerica can vary significantly by town.

For a taller slope, consider building multiple shorter walls in a terraced design. This is often safer, easier to build, and more attractive.

What is the most common reason retaining walls fail?

The single most common cause of retaining wall failure is poor drainage. When water saturates the soil behind a wall, it creates immense hydrostatic pressure. This force can push the wall outwards, causing it to lean, bulge, crack, and eventually collapse.

This type of failure is completely preventable with proper drainage installation. The gravel backfill, perforated drain pipe, and landscape fabric discussed in this guide are not optional—they are essential for a wall that will last for decades instead of just a few years.

Do I need to put gravel behind my retaining wall?

Yes, absolutely. A column of crushed gravel (not rounded pea gravel) directly behind the wall is essential for any lasting concrete block retaining wall construction project.

Crushed gravel is used because its angular shape allows water to drain quickly while the pieces lock together for structural support. This gravel backfill serves two key purposes:

- It provides a fast drainage path for water to reach the perforated drain pipe, relieving dangerous hydrostatic pressure.

- It helps distribute the soil load more evenly across the wall.

The gravel zone should be at least 12 inches wide and extend up to the top of the wall. Do not cut corners by using less gravel or mixing it with soil, as this will compromise the wall’s stability and longevity.

Need a Hand? When to Call the Professionals

Concrete block retaining wall construction is a rewarding DIY project, but it is also physically demanding work that requires precision and patience.

While many homeowners can successfully build a smaller wall, some situations call for professional expertise. Consider calling a professional if your project involves:

- A wall over 3 feet tall

- Challenging soil conditions or a steep slope

- Complex designs with curves or integrated steps

- A wall that must tie into existing structures

Sometimes, the decision is about time and convenience. If you lack the time or simply prefer a guaranteed professional result, the team at AJM Grounds is here to help.

We bring years of experience and professional-grade equipment to every retaining wall construction project. We ensure proper engineering, code compliance, and a structure built to last for decades. We proudly serve residential and commercial clients in Bedford, Billerica, Burlington, Lexington, Reading, Stoneham, Wilmington, Winchester, and our home base of Woburn, MA.

Whether you build it yourself or partner with us, the goal is a safe, functional wall that adds lasting value to your property.