Building the Foundation for Success: Cinder Block Wall Basics

Cinder block wall installation is a rewarding DIY project that provides durability, privacy, and structural support for your property. For those looking to tackle this project, here’s a quick overview of the process:

- Planning & Permits: Check local building codes and obtain necessary permits

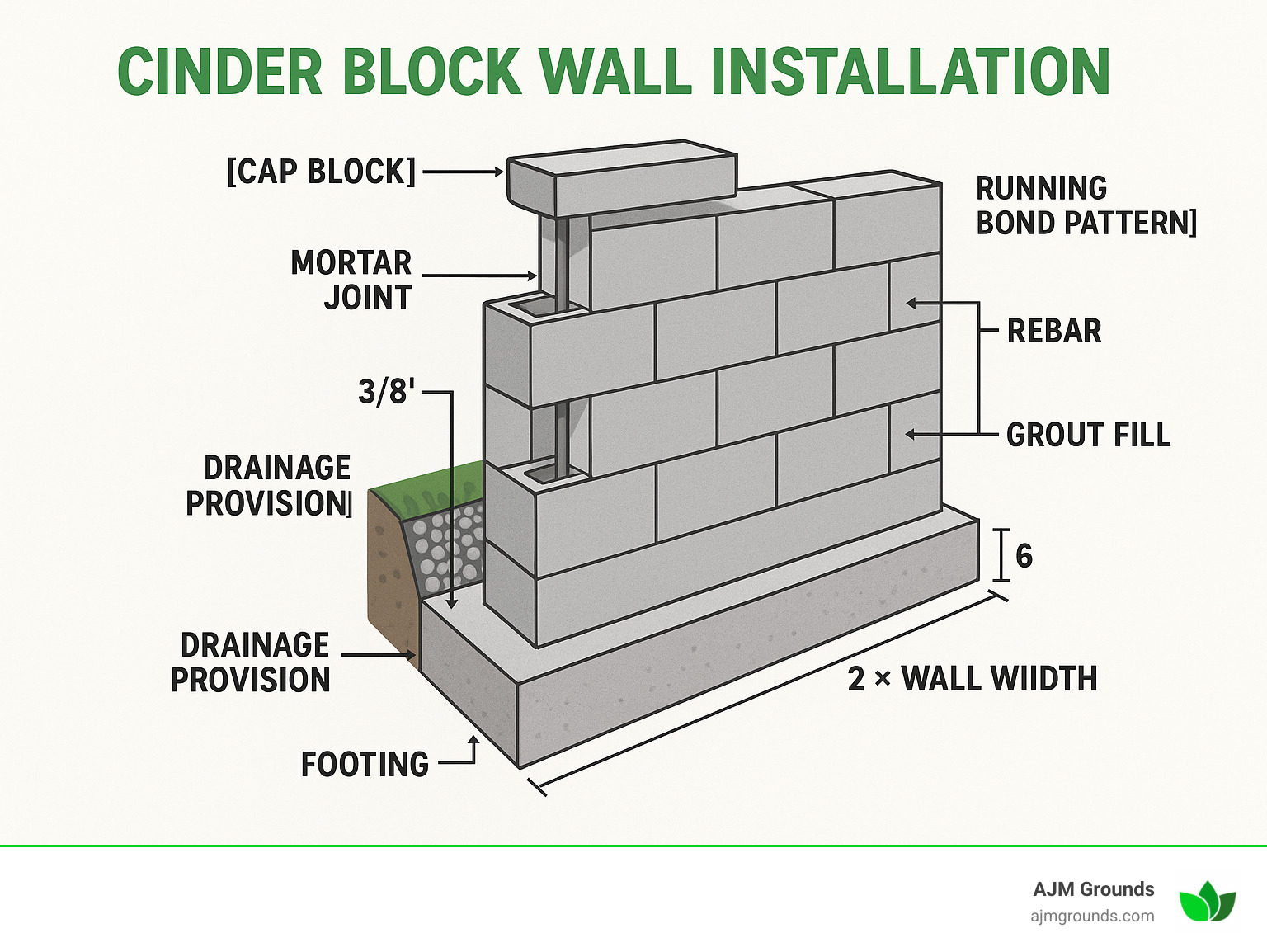

- Foundation Preparation: Dig a trench below frost line, pour concrete footing (twice the wall width)

- First Course: Lay initial blocks on 1-inch mortar bed with 3/8-inch joints

- Building Up: Stack blocks in a staggered pattern, checking level frequently

- Reinforcement: Add rebar vertically every 24 inches and horizontally every third course

- Finishing: Cap the wall and tool joints when thumbprint-hard

Building a cinder block wall gives your yard or garden a special touch, and the final product offers low-maintenance durability that can last up to 80 years with proper care.

Whether you’re creating a retaining wall to prevent soil erosion, constructing a privacy barrier, or building a foundation for an outdoor feature, cinder blocks provide an affordable and versatile solution.

I’m John Caplis, owner of AJM Grounds LLC, and I’ve overseen numerous cinder block wall installation projects throughout Woburn, Massachusetts, helping homeowners transform their outdoor spaces with durable, attractive block walls that complement their landscape design.

Must-know cinder block wall installation terms:

– backyard retaining wall ideas

– retaining wall builders near me

– retaining walls ideas

Understanding Cinder Block Walls & Their Alternatives

Thinking about tackling a cinder block wall installation? Let’s start with understanding what you’re actually working with. Despite what many folks call them, those hefty blocks at the hardware store have some important differences worth knowing about.

True cinder blocks earned their name from their original composition—concrete mixed with coal cinders (those ashy byproducts from coal-burning). Today, what most of us call “cinder blocks” are actually concrete masonry units (CMUs) made primarily with Portland cement, aggregate, and water. The standard size you’ll encounter is approximately 8″×8″×16″.

Those hollow cores serve multiple clever purposes—they reduce weight for easier handling, create space for reinforcement with rebar and grout, improve insulation properties, and can provide channels for utilities when needed.

For typical residential projects, standard cinder blocks offer a minimum compressive strength of 1,900 pounds per square inch (psi), which is plenty strong for most garden walls and non-loadbearing applications around your home.

| Block Type | Weight | Strength | Cost | Best Use |

|---|---|---|---|---|

| Cinder Block | Lighter (25-35 lbs) | 1,900+ psi | $1-3 per block | Non-loadbearing walls, garden walls |

| Concrete Block | Heavier (35-40 lbs) | 2,500+ psi | $2-4 per block | Structural walls, foundations, retaining walls |

| Brick | Lightest (4-5 lbs) | 2,500-3,500 psi | $0.50-1 per brick | Facing, veneer, decorative walls |

Key Differences & When to Use Each

When planning your cinder block wall installation, the differences between materials really do matter for your project’s success.

Density and Weight is your first consideration. True cinder blocks are lighter than concrete blocks thanks to that coal cinder aggregate—your back will thank you during a DIY project! But if you’re building something tall or load-bearing, the extra heft of concrete blocks provides greater structural integrity.

The PSI Rating (or compression strength) is another key factor. Concrete blocks typically withstand greater pressure (2,500+ psi) compared to cinder blocks (1,900+ psi). For a retaining wall that’s holding back a hillside or significant soil pressure, that extra strength makes concrete blocks the smarter choice.

Both types of blocks offer excellent Sound Insulation, making them perfect choices for privacy walls between properties or to buffer street noise—something our clients in busy Massachusetts neighborhoods particularly appreciate.

Codes, Design & Budget Planning

Planning is where the real magic of cinder block wall installation begins. Before you start stacking blocks, let’s make sure you’ve got all your ducks in a row.

Building Codes and Permits

Here in Woburn and neighboring towns like Lexington, Reading, and Stoneham, you’ll need to check with your local building department about permits. Generally speaking, you’ll need official paperwork for walls taller than 4 feet, retaining walls holding back significant weight, or anything close to property lines. Massachusetts winters are no joke, which is why local codes are particularly strict about foundation depth and structural integrity.

Design Considerations

For a proper footing, remember this simple rule of thumb: make it at least twice as wide as your wall. For standard 8-inch blocks, that means a 16-inch wide footing. And in our Massachusetts climate, you’ll need to dig below the frost line – typically 4 feet deep – to prevent winter heaving.

Plan for vertical rebar every 24 inches and horizontal reinforcement every third course. Corners and openings need extra attention with additional reinforcement.

Drainage is absolutely critical, especially for retaining walls. Include a perforated drain pipe at the base, use gravel backfill, and don’t forget those weep holes every 4 feet.

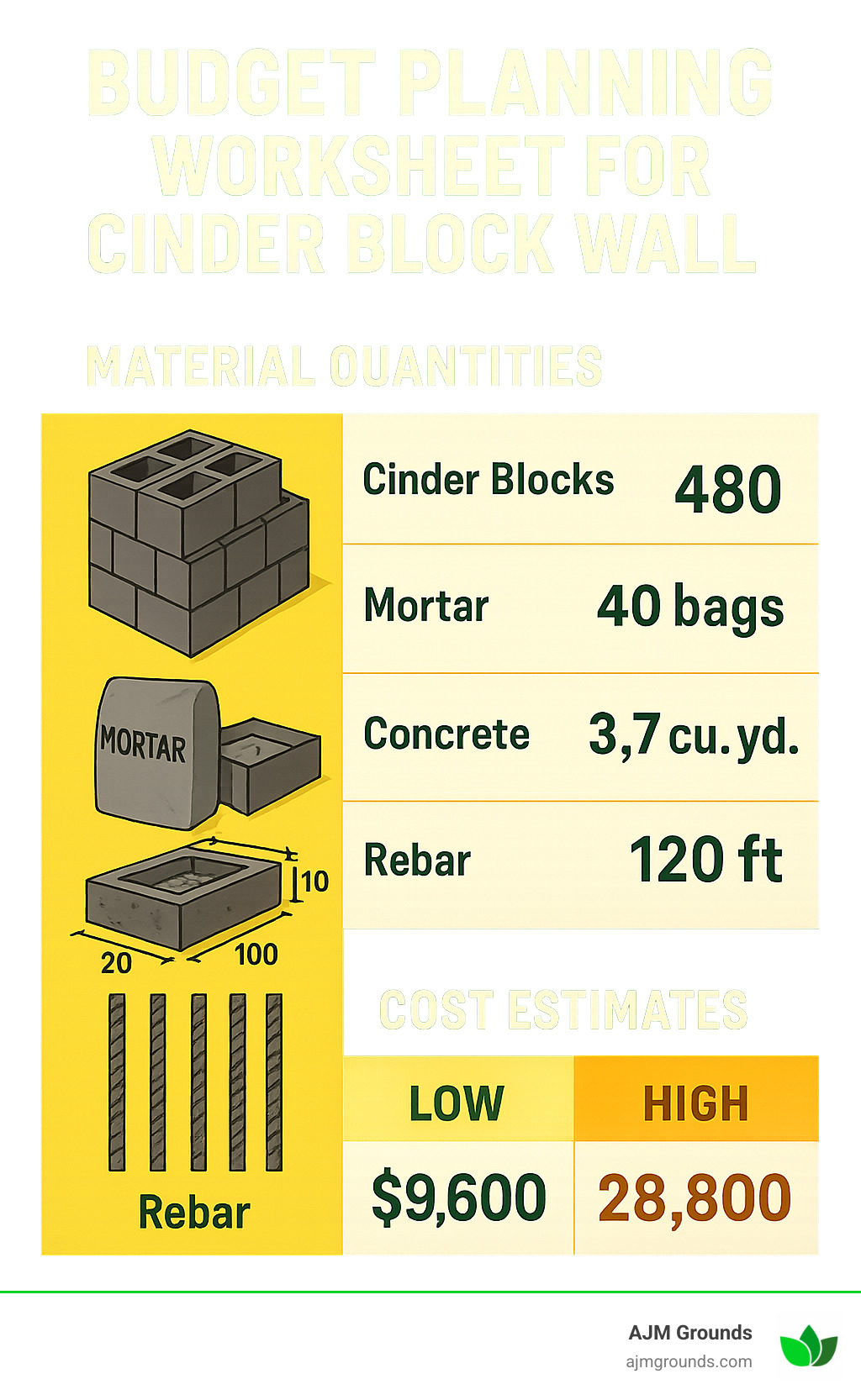

Budget Planning

Based on internet data (not actual AJM Grounds pricing), cinder block wall installation typically runs between $20-$60 per square foot, with premium installations potentially reaching three times the average cost.

When calculating materials, a standard 8″×8″×16″ block covers about 1.125 square feet of wall area. Always add about 5% extra to account for the inevitable broken block or cutting waste. For mortar, an 80-pound bag typically sets 12-14 blocks.

Site Assessment & Measurements

Soil type makes a huge difference in how you approach your foundation. Clay soils expand and contract with moisture changes, demanding deeper footings. Sandy soils drain beautifully but might need extra compaction.

If you’re building on a slope, you’ll need to step your footing to follow the grade while keeping each section level. For steeper slopes, consider creating a terraced effect with multiple walls rather than attempting one tall structure.

Be mindful of height limits for safety and stability. Freestanding walls typically shouldn’t exceed 6-8 feet without specialized engineering, while retaining walls generally max out at 4 feet before requiring professional plans.

Before you dig even an inch, call 811 to locate underground utilities. This free service isn’t just a good idea – it’s required by Massachusetts law and could save you from dangerous and costly accidents.

For more detailed guidance on planning your perfect block wall, check out our comprehensive guide on Block Retaining Wall Design.

Tools, Materials & Prep Work

Getting ready for your cinder block wall installation is half the battle. Having everything on hand before you start will make your project go much more smoothly.

You’ll need a good mason’s line and line blocks to keep everything straight, a 4-foot level, and both pointed and rectangular mason’s trowels. For mixing mortar, a sturdy wheelbarrow and mixing hoe are must-haves. Don’t forget safety gear! Quality gloves, goggles, and a dust mask are essential.

As for materials, you’ll need Type S mortar mix, which offers the high strength necessary for exterior applications. For a typical 10-foot by 6-foot wall, plan on about 75 standard blocks plus 5% extra for inevitable breakage. You’ll also need 3-4 bags of mortar, 6-8 pieces of #4 rebar (½-inch diameter) for reinforcement, and about 1-2 cubic yards of concrete for the footing.

If you’re building a retaining wall, don’t forget the drainage materials—perforated pipe and gravel are essential to prevent water buildup behind the wall. A beautiful finishing touch comes from cap blocks or coping stones.

For more detailed guidance on the installation process itself, our Block Wall Installation page provides step-by-step instructions you might find helpful.

Footing & Foundation Checklist

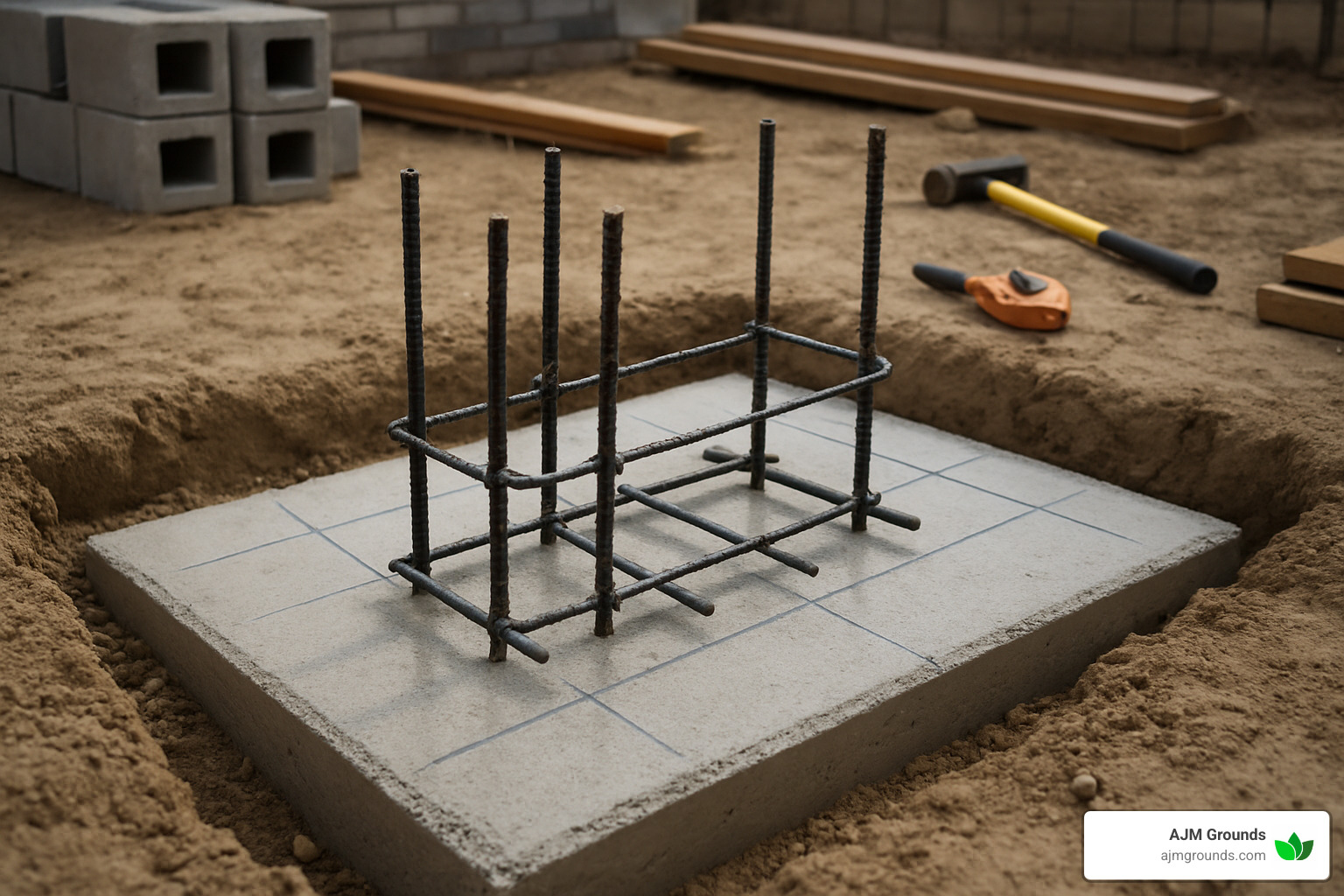

The foundation truly makes or breaks your cinder block wall installation. Start by digging a trench that extends below the frost line—that’s typically 4 feet deep in our Massachusetts climate. Make your trench width at least twice the width of your blocks (so 16 inches for standard 8-inch blocks).

Before pouring concrete, add 4-6 inches of compacted gravel as a base layer. Then build your forms using 2×8 or 2×10 lumber, securing them with stakes and checking for level in all directions.

Install horizontal rebar in a grid pattern (typically 12 inches on center) and leave vertical rebar sticking up every 24 inches where your block cores will align. When you’re ready to pour, mix your concrete to a workable consistency and pour it all at once for the strongest result.

After pouring, create a slightly rough texture on top with a notched trowel—this helps the mortar grip better when you start laying blocks. Allow your concrete to cure for at least 7 days before building on it.

For technical specifications on concrete masonry unit sizes and configurations, the Scientific research on CMU sizes provides excellent reference material.

Cinder Block Wall Installation Step-by-Step

Now that you’ve prepared your site and gathered your materials, it’s time to roll up your sleeves and begin the actual cinder block wall installation.

Preparing for Cinder Block Wall Installation

Before laying your first block, ensure your foundation has cured for at least 7 days. Give the footing surface a good sweep to remove any debris that might interfere with your mortar bond.

Snap chalk lines directly on the footing to mark exactly where your wall will sit. Lightly dampen the footing surface before you begin—not puddle-wet, just enough to prevent it from sucking moisture out of your mortar too quickly.

Set up your mason’s lines at each end using line blocks or corner poles, making sure they’re perfectly level and positioned at the height of your first course.

Mixing Mortar for Cinder Block Wall Installation

Follow the manufacturer’s instructions (typically 5-6 quarts of water per 80-pound bag), but be prepared to adjust based on weather conditions. Always add water to your mixing container first, then gradually introduce the dry mortar.

When your mortar is ready, it should pass the “hang test”—sticking to an upside-down trowel held at a 90-degree angle without sliding off. On hot days, keep your mortar covered between uses and don’t mix more than you can use in 1-2 hours.

The V-furrow technique is ideal for applying mortar to the footing. Spread a generous 1-inch thick bed along your chalk line, then use your trowel to create a V-shaped channel in the center.

Laying the First Course

Begin at the corners or ends of your wall, applying that V-furrowed mortar bed to the footing. Place your first corner block, pressing it firmly into the mortar, then give it a gentle tap with your rubber mallet to seat it properly.

Check for level in all directions—side to side, front to back, and diagonally. Once your corner block is perfectly positioned, butter the end of your next block with mortar and place it against the first, maintaining that crucial 3/8-inch joint spacing.

For retaining walls, incorporate weep holes every 4 feet along the first course.

Building Up and Creating Corners

Begin your second course with a half block to create that classic staggered pattern known as a running bond. Apply a full bed of mortar along the top of your first course, and don’t forget to butter the ends of each block before placing them.

At corners, create interlocking patterns by alternating the orientation of your blocks. This creates a woven effect that significantly strengthens these vulnerable points in your wall.

Reinforcing & Grouting

Position vertical rebar every 24 inches, making sure each piece aligns with the hollow cores in your blocks. After every third course, incorporate horizontal reinforcement.

Your grout should have a pourable consistency. Pour it carefully into the cores containing rebar, using a thin rod to tamp it down and eliminate air pockets.

For more detailed information about reinforcement techniques specifically for retaining walls, visit our comprehensive guide on Retaining Wall Construction.

Finishing Touches & Aesthetics

Once your mortar joints reach that perfect “thumbprint hard” consistency, use a jointing tool to compress and shape them. Always tool horizontal joints first, then verticals.

Capping your wall provides essential protection from the elements. Apply a generous bed of mortar to your top course and place cap blocks with a slight outward slope to encourage water runoff.

Before calling it a day, clean any excess mortar from your block faces and thoroughly rinse all your tools with water. Consider applying a quality concrete sealer after your wall has fully cured (typically 28 days).

Maintenance, Troubleshooting & When to Call a Pro

Your cinder block wall installation is complete—now what? With proper care, these sturdy structures can last up to 80 years, standing strong through Massachusetts winters and summer storms alike.

Regular Maintenance

Each spring, take a slow walk along your wall with a keen eye. Look for any cracks developing in the mortar joints, check that the wall remains plumb, and ensure water is draining properly away from the structure.

That white, chalky substance you might notice on your blocks? That’s efflorescence—mineral deposits left behind when water evaporates. While it looks concerning, it’s usually just cosmetic. A simple solution of one part vinegar to ten parts water and a stiff brush will typically do the trick.

Every few years, applying a quality masonry sealer will provide an invisible shield against moisture damage. Choose breathable sealers that allow the wall to “exhale” trapped moisture while keeping rain out.

Common Problems and Solutions

Hairline cracks in mortar joints are often just normal settling and usually nothing to worry about—just keep an eye on them to make sure they don’t grow.

When you spot diagonal cracks, however, that’s your wall telling you something more serious might be happening with the foundation. And horizontal cracks? Those are the ones that should prompt immediate attention, as they often indicate pressure problems that could lead to failure.

For retaining walls that start to lean or bulge, drainage issues are the likely culprit. Water builds up behind the wall, creating hydrostatic pressure that pushes against the structure.

Based on internet data (not actual AJM Grounds pricing), repairing block walls typically costs between $10-$30 per square foot, with the high end being at least 3x average pricing.

When to Call a Professional

For walls taller than 4 feet, retaining walls on challenging slopes, or any wall showing significant structural issues, professional help isn’t just nice—it’s necessary.

Complex projects like curved walls or integrating your wall with existing structures require specialized skills and experience. Similarly, if you’re planning to run electrical conduit or plumbing through your wall, professional installation ensures everything meets code requirements.

When it comes to repairs, use this simple rule: if the problem affects the structural integrity of your wall, it’s time to call in reinforcements. Significant leaning, bulging sections, wide cracks, or foundation issues are all red flags that warrant professional attention.

For more detailed information about our professional repair services, visit our page on Retaining Wall Repairs.

Frequently Asked Questions about Cinder Block Walls

Do cinder block walls need a separate footing?

Absolutely! This is one of the most crucial aspects of cinder block wall installation that simply can’t be skipped. Every cinder block wall needs a proper concrete footing to stand the test of time.

Think of the footing as the wall’s foundation – it spreads the weight across a larger area and prevents the wall from sinking or shifting. Here in Massachusetts, where we deal with significant frost heave, your footing must extend below the frost line (typically 4 feet deep) to prevent seasonal movement that would crack and destabilize your wall.

The footing should be at least twice as wide as your wall (so a 16-inch footing for an 8-inch block) and reinforced with rebar running in both directions.

How do I integrate electrical or plumbing lines?

Planning for utilities during your cinder block wall installation makes life so much easier than trying to add them later. For electrical work, you’ll want to map out your conduit routes before laying a single block. Install conduit sleeves through the footing where needed, and consider which block cores will carry vertical runs.

When it comes to plumbing, it’s best to avoid embedding water supply lines directly in block walls whenever possible. If pipes must pass through the wall, use sleeves that are half an inch larger than the pipe and waterproof these penetrations thoroughly.

Before tackling either of these tasks, consult with licensed professionals. Electrical and plumbing work must meet specific code requirements, and a quick consultation can save you from costly mistakes.

What are common mistakes to avoid?

The most common foundation issues include footings that aren’t deep enough to escape frost heave, footings that are too narrow for the wall width, and inadequate soil preparation.

Mortar problems frequently trip up DIYers too. Consistency is key – mortar that’s too wet slumps and creates messy joints, while mortar that’s too dry won’t bond properly.

Structural weaknesses often stem from improper reinforcement or failing to maintain the running bond pattern. For retaining walls, drainage oversights can be catastrophic. Without proper drainage behind the wall, hydrostatic pressure builds up and can topple even the most solidly built structure.

Conclusion

Building a cinder block wall installation is certainly no small undertaking, but it’s one that pays dividends in durability, functionality, and curb appeal. When you follow the proper techniques we’ve outlined, your wall can stand strong for decades with minimal upkeep, becoming a lasting feature of your landscape.

I’ve seen how a well-built block wall can transform a sloped backyard in Reading into usable garden space, provide privacy for a Stoneham homeowner’s pool area, or create a neat boundary for a Wilmington property. No matter where you’re located in Massachusetts, the fundamentals remain consistent: start with a solid foundation, place each block with care, reinforce appropriately, and never neglect proper drainage.

Here at AJM Grounds, we take genuine pride in our craftsmanship when installing block walls throughout Woburn and neighboring communities. Each project we undertake is approached with personalized attention because we understand that your outdoor space is uniquely yours.

Maybe you’ve read through this guide and feel excited to tackle your cinder block wall installation as a DIY project. Or perhaps you’re thinking, “This seems like a lot to handle on my own.” Either way, you’re making a smart choice by educating yourself on the process. If you decide the scope feels overwhelming, our experienced team is ready to help bring your vision to life with the same care and attention to detail you’d put into it yourself.

For more information about our professional retaining wall services, you can explore our detailed page on Retaining Wall Construction or reach out directly to discuss your specific project needs.

Whether you choose the DIY route or bring in professionals, the quality of your wall ultimately comes down to thorough preparation, premium materials, and meticulous execution.