The Science of Strong Walls: Block Retaining Wall Design Essentials

Block retaining wall design is the process of planning and constructing walls that hold back soil while creating usable space on sloped properties. For best results, follow these key principles:

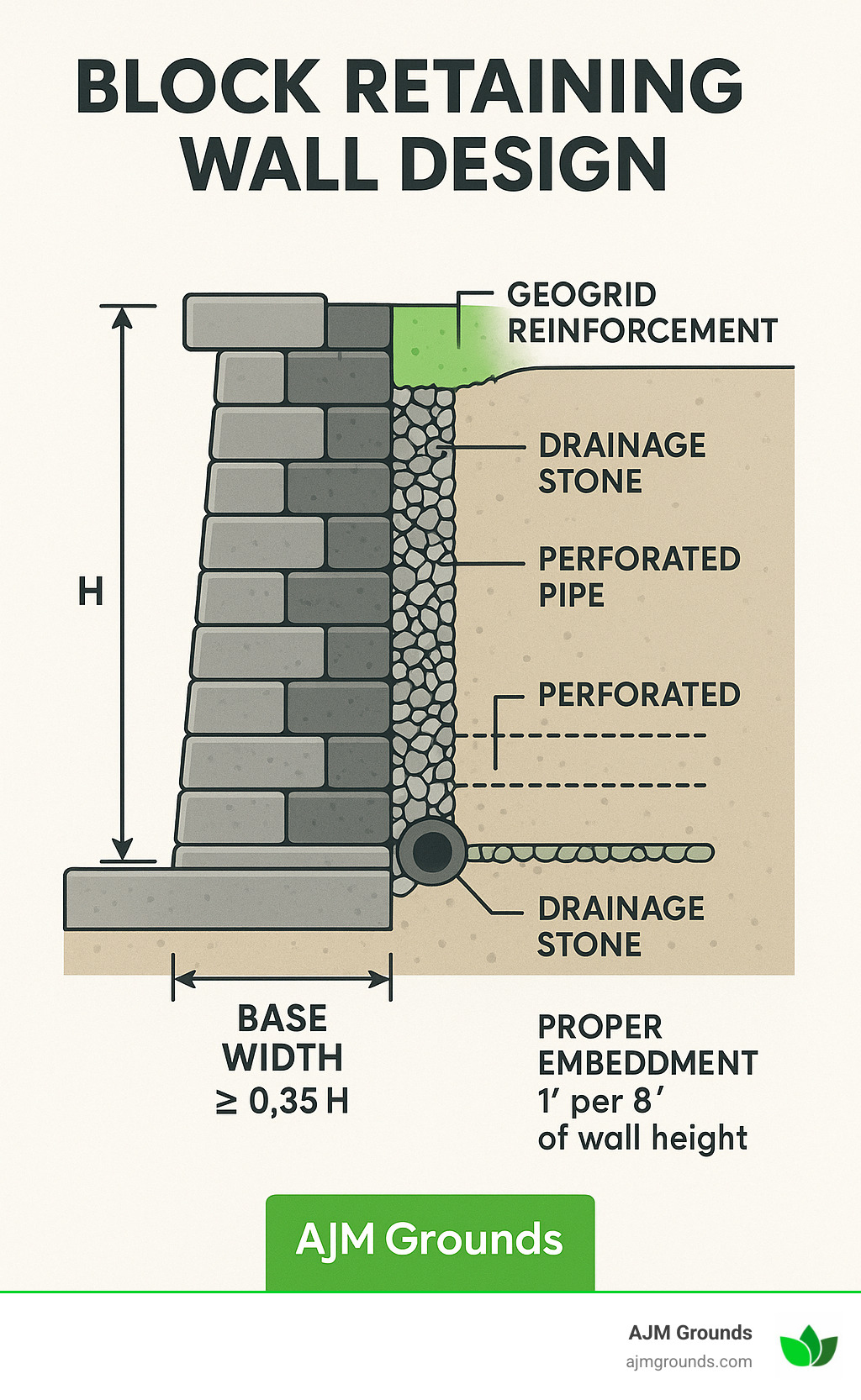

- Base Width: Make the base length at least 35% of the wall height

- Drainage: Install clean crushed stone (#57) and perforated pipe behind the wall

- Reinforcement: Use geogrid for walls over 4 feet tall

- Embedment: Bury the first course 1 inch for every 8 inches of wall height

- Engineering: Consult a professional for walls over 4 feet or supporting heavy loads

A properly designed retaining wall does more than just hold back earth – it transforms unusable slopes into functional outdoor living spaces while preventing erosion and managing water runoff. What many homeowners don’t realize is that a 4-foot-high, 15-foot-long retaining wall can be holding back as much as 20 tons of saturated soil!

Creating a stable block retaining wall isn’t just about stacking blocks. It requires careful planning, proper materials, and understanding the forces at work. The wall must resist both the lateral pressure from soil and the hydrostatic pressure from water buildup behind it.

The right design balances three critical elements: structural support, drainage, and erosion control. Skipping any of these can lead to bulging, cracking, or complete wall failure – costly mistakes that are entirely preventable with proper planning.

My name is John Caplis, and as the owner of AJM Grounds LLC, I’ve designed and installed numerous block retaining wall designs throughout Woburn and surrounding areas, helping homeowners transform problematic slopes into beautiful, functional spaces. Let me guide you through creating a retaining wall that will stand strong for decades.

Explore more about block retaining wall design:

– backyard retaining wall ideas

– concrete retaining wall builders

– retaining wall builders near me

Block Retaining Wall Design Fundamentals

When you’re looking at that sloped area in your yard, imagining what it could become with the right retaining wall, understanding the basics of block retaining wall design makes all the difference. At AJM Grounds, we’ve built hundreds of these walls throughout Woburn and nearby communities, and we’ve learned that a successful wall starts with solid fundamentals.

Most block walls fall into two main categories: gravity walls and mechanically stabilized earth (MSE) walls. Gravity walls are simpler structures that use just their weight to hold back soil. MSE walls, which we often recommend for taller applications, incorporate geogrid reinforcement layers that extend into the soil behind the wall, creating a much stronger integrated structure.

Today’s segmental block systems have revolutionized retaining walls with their clever design. They connect without mortar, making installation faster. Their interlocking features create natural stability. With compressive strengths typically over 5000 PSI, these blocks can handle serious pressure while still offering beautiful textures and colors to complement your landscape.

What Makes a Block Retaining Wall Different?

The genius of a block retaining wall design is how it works with natural forces rather than fighting them. Unlike poured concrete walls that are rigid, block walls have slight flexibility that allows them to adjust to minor ground movement without cracking.

This is especially valuable in our New England climate, where freeze-thaw cycles can wreak havoc on rigid structures. Our clients in Woburn and surrounding towns appreciate that these walls distribute soil pressure across multiple units instead of concentrating it in one spot. They manage water pressure through built-in drainage features, create mechanical interlock between courses for stability, and if damage ever occurs, individual blocks can be replaced without rebuilding the entire wall.

Types of Systems & How They Work

Walking through a home improvement store, you’ll notice several different block systems available:

Gravity Systems rely simply on the weight and setback of the blocks to create stability. These work well for shorter applications, typically under 4 feet in height.

Pinned Systems use fiberglass or concrete pins connecting each course to the one below. This clever approach adds significant stability and allows for nearly vertical walls when space is tight.

Lip Systems feature a built-in lip on the bottom of each block that automatically creates the proper setback when stacked, ensuring structural integrity with minimal effort.

Geogrid MSE Systems incorporate layers of polymer mesh (geogrid) that extend into the backfill, essentially creating a reinforced soil mass that becomes part of the wall system. This approach allows for much taller walls while maintaining safety.

A critical factor in any wall design is the active earth pressure coefficient (Ka), typically around 0.33 for good granular soils. This value helps determine how much lateral pressure the soil will exert on your wall. Using the right value prevents both overbuilding (wasting money) and underbuilding (risking failure).

Primary Keyword Spotlight: Block Retaining Wall Design vs. Other Materials

When comparing block retaining wall design to alternatives, several factors come into play:

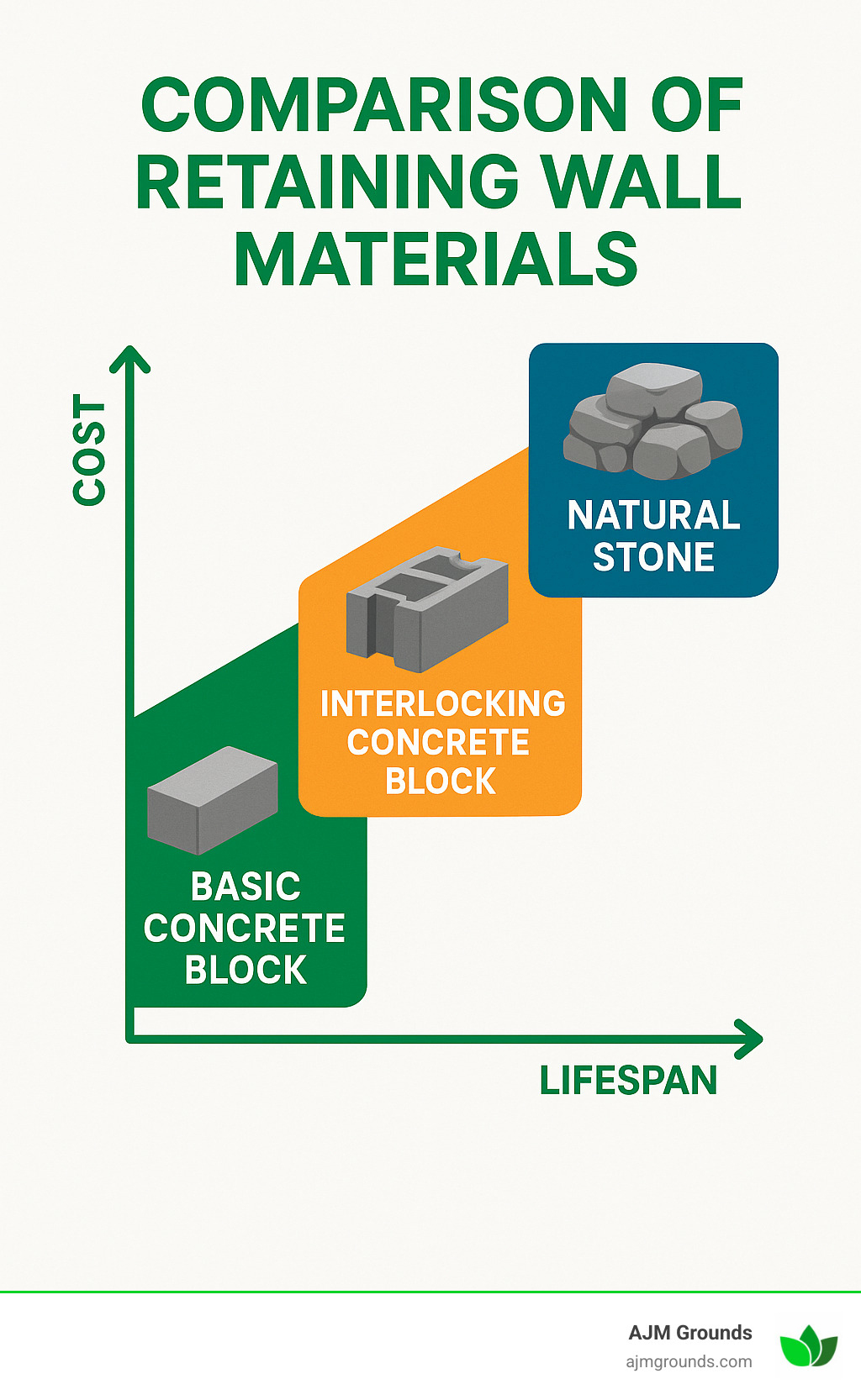

Timber walls might seem budget-friendly at first ($15-$90 per square foot installed), but their 10-15 year lifespan makes them less economical long-term. In our moisture-rich Massachusetts environment, wood deterioration is inevitable.

Stone walls offer best natural beauty at $20-$300 per square foot, but require significant masonry skill. They’re excellent for lower walls but become increasingly complex as height increases.

Concrete block walls strike an excellent balance at $30-$150 per square foot for standard systems. Their modular nature simplifies installation, and with a 40+ year lifespan when properly installed, they provide excellent value.

Interlocking concrete block systems range from $45-$270 per square foot installed, depending on complexity and site conditions. While potentially more expensive upfront, their performance and longevity make them worth considering for important projects.

Here’s how these materials compare:

| Material | Cost Range (per sq ft) | Max Height (without engineering) | Expected Lifespan |

|---|---|---|---|

| Timber | $15-$90 | 3-4 feet | 10-15 years |

| Stone | $20-$300 | 3-4 feet | 100+ years |

| Concrete Block | $30-$150 | 4 feet | 40+ years |

| Interlocking Block | $45-$270 | 3-4 feet (more with geogrid) | 50+ years |

Note: These are average costs based on internet data and not actual costs for AJM Grounds.

When choosing your wall material, consider not just the initial cost but also longevity, maintenance requirements, and how the finished product will improve your property’s value and appearance. After all, a well-designed retaining wall isn’t just functional—it becomes a defining feature of your landscape.

Engineering & Site Analysis Essentials

Proper block retaining wall design begins with thorough site analysis and engineering considerations. At AJM Grounds, we start every project in Woburn and surrounding communities with a comprehensive evaluation of site conditions.

When I’m evaluating a site for a new retaining wall, I’m looking at much more than just the slope. The soil beneath your feet tells a story about how your wall needs to be built. Clay soils, which we often encounter in parts of Woburn, hold water like a sponge and create significantly more pressure than sandy soils. This is why we never skip soil analysis – it’s the foundation of everything that follows.

Understanding active earth pressure is crucial too. We calculate this using the soil’s internal friction angle and something called the Ka coefficient (typically around 0.33 for good soils). Think of this as measuring exactly how hard your soil will “push” against your wall when it’s wet and heavy.

Here in Massachusetts, frost is another major consideration. Our frost can penetrate 4 feet or deeper, which is why proper foundation depth is non-negotiable. A wall that isn’t built below the frost line is essentially sitting on a layer that will heave and shift seasonally.

Any additional weight above your wall – whether it’s a driveway, a shed, or even regular foot traffic – creates what engineers call “surcharge loads.” These invisible forces dramatically increase the pressure on your wall and must be factored into the design. I’ve seen perfectly good walls fail simply because someone parked heavy equipment above them that wasn’t accounted for in the original design.

Professional block retaining wall design always includes safety factors – typically 1.5 for both overturning and sliding. This means your wall is engineered to be 50% stronger than the minimum required strength. It’s not overkill; it’s peace of mind.

For walls near water features, special considerations apply. We’ve installed many walls near ponds and areas with high groundwater throughout Woburn and Burlington. In these cases, we extend drainage stone to the full height of the wall and use specialized filter fabrics that prevent soil migration while allowing water to pass through. You can learn more about these specialized applications at Water Applications for Retaining Walls.

Determining Height, Setback & Base Width

The relationship between wall height, setback, and base width forms the backbone of stable block retaining wall design. These aren’t arbitrary measurements – they’re carefully calculated ratios that work together to create stability.

The embedment rule is straightforward but crucial: bury the first course of blocks approximately 1 inch for every 8 inches of wall height. For your typical 4-foot wall (48 inches), that means 6 inches should be below grade. This buried portion provides critical stability against the forces trying to push your wall forward.

Base width is equally important. For gravity walls with a vertical face, you’ll need a base that’s at least 35% of the total wall height. So that same 4-foot wall needs a base at least 16.8 inches wide. Think of this as the wall’s footprint – too narrow, and it becomes top-heavy and unstable.

Most modern block systems incorporate a slight backward lean, or “batter,” of approximately 1 inch per vertical foot. This isn’t just an aesthetic choice – it dramatically improves stability by positioning the wall’s center of gravity more favorably against both sliding and overturning forces. It’s like leaning back slightly when someone’s trying to push you over – a little angle makes a big difference in stability.

These measurements are starting points. The unique conditions of your property may require adjustments, which is why professional engineering becomes essential for taller or more complex walls.

Drainage & Reinforcement—The Heart of Reliable Block Retaining Wall Design

In my 15+ years of building retaining walls throughout Massachusetts, I’ve learned one truth above all others: drainage and reinforcement make or break a wall. You can use the most expensive blocks on the market, but without these two elements, you’re building on borrowed time.

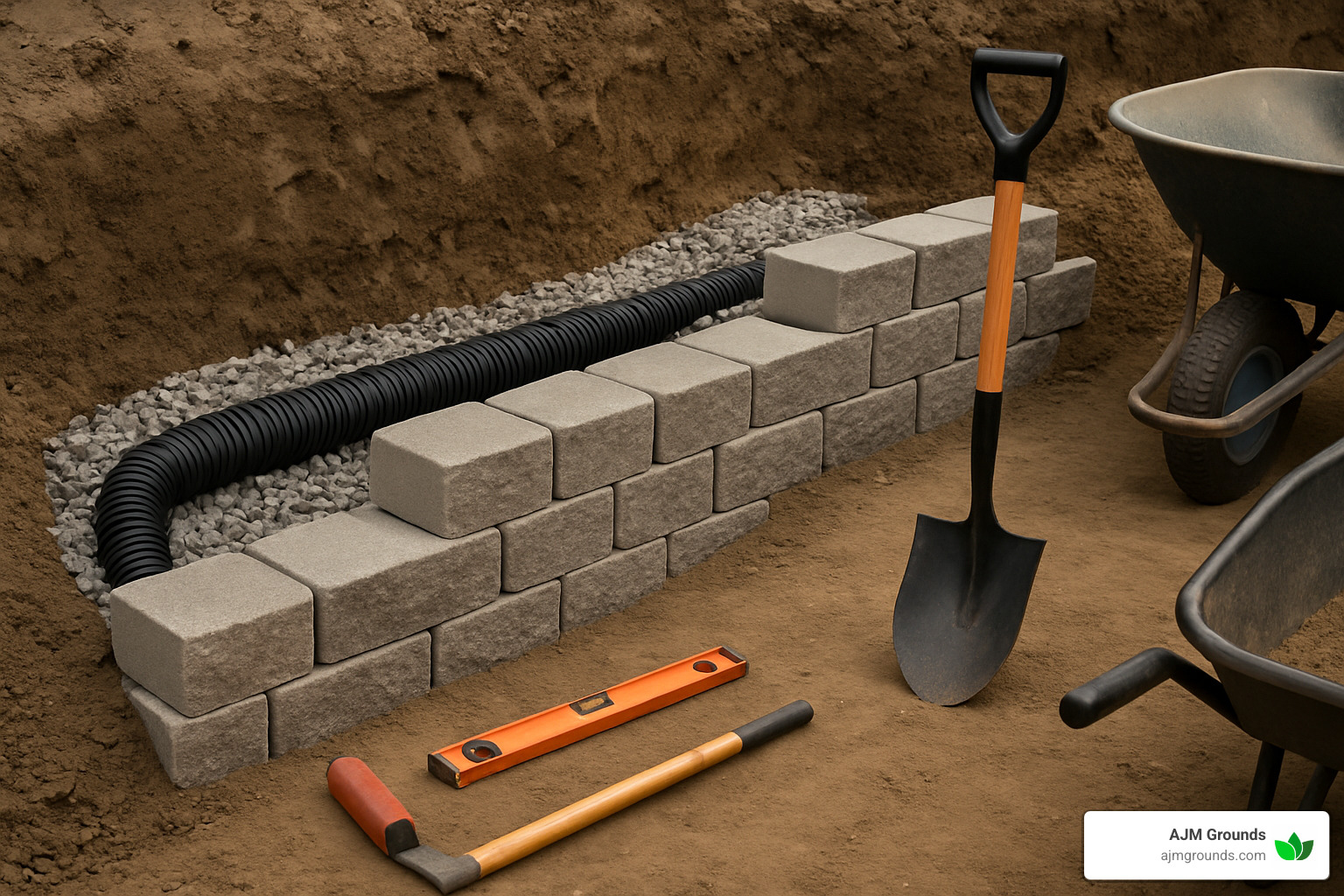

Good drainage starts with clean crushed stone – specifically #57 stone (¾-inch). We install a minimum of 12 inches behind every block retaining wall design. This material is magical for walls because the angular pieces lock together while still leaving plenty of space for water to flow through. It’s like creating a giant filter behind your wall.

At the base, we always install a 4-inch perforated pipe wrapped in filter sock, gently sloped to daylight or a drainage system. This pipe acts as a highway for water, directing it away from your wall before pressure can build up. Water is patient but relentless – it will find every weakness if not properly managed.

Between the drainage stone and the backfill soil, we place non-woven geotextile fabric. This remarkable material performs a balancing act – preventing soil from washing into your drainage stone while allowing water to pass through freely. We specifically avoid woven fabrics as they tend to clog over time, defeating their purpose.

As we’ve highlighted in our article on The 5 Most Important Reasons Why Proper Drainage in Your Landscape is So Important, proper drainage prevents wall failure from hydrostatic pressure, stops erosion of surrounding soil, prevents frost heaving during our harsh New England freeze-thaw cycles, and keeps the reinforced soil zone from becoming saturated.

For walls over 3-4 feet tall, geogrid reinforcement becomes essential. This synthetic mesh material extends into the soil behind the wall, creating a stronger, unified mass. The general rule of thumb is that geogrid length should equal the wall height – so a 6-foot wall needs 6-foot geogrid layers. We typically install these layers every 16-24 inches of wall height, extending them perpendicular to the wall face, with carefully compacted soil over each layer before the next course of blocks is placed.

When You Need Engineering & Permits

Knowing when to bring in professional engineering isn’t just about following rules – it’s about ensuring safety and longevity for your block retaining wall design. After building hundreds of walls throughout Woburn, Winchester, and surrounding towns, I’ve developed a clear sense of when expert help is needed.

Professional engineering becomes necessary when your wall exceeds 4 feet in height (measured from the bottom of the base to the top of the wall), when it supports structures or driveways creating surcharge loads, or when it’s near a pool, building foundation, or property line. Unusual soil conditions, tiered walls where upper walls affect lower ones, and areas with water issues or high groundwater also trigger the need for engineering.

Permit requirements vary between municipalities. In most communities we serve, walls over 3-4 feet require permits and engineered drawings. I always recommend checking with your local building department before starting construction – it’s much easier to get permits upfront than to deal with stop-work orders later.

While engineering adds to the initial cost, it’s an investment that pays dividends in safety and longevity. A properly engineered wall might cost more upfront but will save thousands in potential repairs or liability issues down the road. I’ve seen too many DIY walls fail after a few seasons because they lacked proper engineering – an expensive lesson I’d rather help my clients avoid.

If you’re considering a retaining wall project in Woburn or surrounding areas, our team at AJM Grounds can help determine whether your project requires engineering and guide you through the permit process. For walls needing repair, our Retaining Wall Repairs service can help address issues before they become major problems.

Building & Reinforcing Your Wall Step-by-Step

Once the planning and engineering are complete, the actual construction of your block retaining wall design follows a systematic process. At AJM Grounds, we’ve refined our installation techniques through hundreds of projects across Woburn, Bedford, Billerica, and beyond.

Site Prep & Base Course

The foundation of your wall is like the foundation of a house – get it right, and everything else falls into place. Skip the details here, and you’ll be rebuilding sooner than you’d like!

Before breaking ground, always call Dig Safe at 811 at least 72 hours before you start. This free service marks underground utilities and can save you from a very bad day. Trust me, hitting a gas line or fiber optic cable is not how you want to start your project.

For the trench, think wider than you might expect – you’ll need the block width plus an additional 12 inches. This gives you room to work and ensures proper drainage. The depth needs to accommodate both your buried block portion and a solid 6-inch gravel base.

The gravel base is your wall’s unsung hero. We use ¾-inch crushed stone, compacted thoroughly with multiple passes of a plate compactor. This step might seem tedious, but it prevents settling that can crack your wall later. I always tell our Woburn clients: “Spend the extra hour on the base, save years on the wall’s life.”

When laying that first course, precision is everything. Each block must be perfectly level in all directions. Use a string line to keep everything aligned – even a half-inch deviation now can turn into several inches of misalignment by the time you reach the top.

Stacking, Backfilling & Installing Geogrid

With your foundation set, the wall starts taking shape through a rhythmic process of stacking, backfilling, and reinforcing.

The blocks should follow a running bond pattern – like traditional brickwork where each block sits over the joint between blocks below. This creates structural integrity through the entire wall. Before adding each new course, take a moment to sweep the tops clean. Even small pebbles can throw off your level.

Drainage stone is added in 6-inch lifts behind the wall. This isn’t just filler – it’s a crucial drainage pathway that prevents water pressure from building up. Each lift needs proper compaction before adding the next course. One shortcut I’ve seen homeowners take is skipping this compaction – only to watch their wall bulge after the first heavy rain.

For walls over 3-4 feet, geogrid becomes your best friend. This synthetic mesh material extends perpendicular to the wall face, creating a reinforced soil mass that acts as part of the wall system. The geogrid length typically equals the wall height – so a 6-foot wall needs 6-foot geogrid layers. Install it at specified intervals (usually every 16-24 inches of height), pull it taut, and stake it temporarily while adding backfill.

Remember to keep heavy equipment at least 3 feet away from the back of your wall. The vibration and weight can destabilize your carefully constructed work. I learned this lesson the hard way on an early project in Burlington – watching a wall shift before my eyes as a skid steer got too close!

Finishing Touches: Caps, Curves & Block Retaining Wall Design Details

The final phase of your block retaining wall design is where function meets beauty – and where your wall truly becomes part of your landscape.

Cap installation isn’t just decorative – it’s functional too. Caps protect the top course and give the wall a finished look. Before placing caps, clean the top course thoroughly and apply a high-quality masonry adhesive like DAP Landscape Block Adhesive. This keeps the caps from shifting over time. For curved walls, you’ll either need special cap units or you’ll have to cut standard caps to fit the radius.

Curves require special attention throughout construction. Inside curves create gaps between blocks at the top that may need to be filled with cut pieces. Outside curves often require trimming the backs of blocks to maintain the proper radius. It takes more time, but the visual payoff is worth it.

Don’t forget to plan for special features during construction. If you want landscape lighting, install conduit as you build. For drainage outlets, use solid pipe through the wall face with proper screening to prevent animals from nesting. These details are much easier to incorporate during construction than to add later.

The area around your wall deserves attention too. Restore grades to direct water away from the wall, add topsoil and appropriate plantings, and consider mulch at the base to prevent damage from weed trimmers. Your wall should blend with its surroundings while performing its structural job.

You can see how these finishing details transform a simple retaining wall into a landscape feature in our Retaining Wall with Paver Patio portfolio. The right caps, curves, and details don’t just complete your wall – they lift it from functional to fantastic.

Throughout the entire building process, we maintain our focus on both the structural integrity and the aesthetic appeal. A properly built wall should look beautiful for decades, not just the first season. That’s the difference professional installation makes – and it’s why our walls throughout Woburn and surrounding communities stand the test of time.

Costs, Quantities, Maintenance & Design Inspiration

When planning your block retaining wall design, understanding the numbers can save you from budget surprises and material shortages. At AJM Grounds, we’ve helped countless homeowners throughout Woburn and nearby communities transform their sloped yards into beautiful, functional spaces—and we’ve learned that good planning makes all the difference.

Estimating Blocks, Drain Stone & Geogrid

Calculating materials accurately is both an art and a science. To estimate the number of blocks needed, divide your wall length by the length of each block to determine blocks per row. Then divide the wall height by the block height to find the number of rows needed. Multiply these numbers together for your base quantity, then add about 10% extra to account for cuts and waste—something we’ve learned is essential after countless projects where that last pallet saved the day!

For drainage stone, you’ll need a volume equal to your wall’s length multiplied by its height and by at least one foot of width (the minimum drainage zone). To convert this to tons, divide the cubic footage by 20, which will give you the amount of ¾-inch stone required.

If your wall includes geogrid reinforcement, measure the wall length for linear feet per layer, with the width typically equaling the wall height for basic designs. You’ll generally need a layer every 16 inches of height, though engineering specs may vary. Multiply these dimensions to calculate total square footage.

Don’t forget the supporting players—drainage pipe (wall length plus 10%), filter fabric (drainage zone area plus 20% for overlap), and cap adhesive (one tube covers roughly 10-15 linear feet). For complex projects, we’re always happy to provide detailed material takeoffs as part of our design services.

Price Ranges & Budget Tips (Internet Averages)

Budget planning for your block retaining wall design starts with understanding typical costs. Based on internet data (not AJM Grounds pricing), basic concrete block walls typically range from $30-$150 per square foot installed. Interlocking concrete block systems generally run $45-$270 per square foot, while natural stone varies from $20-$300 per square foot.

Several factors influence these wide ranges: wall height and length, site accessibility, excavation requirements, engineering needs, soil conditions, block style, and special features like curves or steps. Complex sites with difficult access or poor soil can significantly increase costs, while simple, straight walls on easy-to-reach locations represent the lower end of the spectrum.

To maximize your budget, consider breaking one tall wall into multiple terraced walls—often more economical and visually interesting. Using standard blocks with decorative caps rather than premium blocks throughout can create a high-end look at a more moderate price. Some homeowners also choose to handle simple site preparation themselves before we arrive for the technical installation work.

Keeping Your Block Retaining Wall Design Performing for Decades

A well-built retaining wall is an investment that should last generations—with the right maintenance. We recommend an annual spring inspection after the freeze-thaw cycles of a Massachusetts winter. Check for any block movement, make sure drainage outlets remain clear, look for signs of erosion, and verify that water still flows away from the wall top.

Regular maintenance is simple but crucial. Clear leaves and debris from behind the wall and from drainage outlets, especially after fall in our leaf-heavy New England landscape. Be vigilant about removing deep-rooted plants that sprout too close to the wall—those innocent-looking maple seedlings can become structural problems as they grow. If you notice hairline cracks, apply a masonry sealant before winter arrives, and regrade any areas that have settled to maintain proper drainage.

Every few years, consider a professional cleaning to remove the inevitable staining that occurs in our humid climate. Replace any damaged blocks promptly, and re-secure loose caps with fresh adhesive before they become projectiles during lawn mowing. For walls showing signs of more significant issues, our Retaining Wall Repairs service can address problems before they lead to failure.

Style & Trend Ideas to Lift a Block Retaining Wall Design

Today’s block retaining wall design options go far beyond the utilitarian walls of the past. Modern trends include multi-face panel systems that display varied textures on a single wall, creating visual interest without added complexity. We’re increasingly incorporating built-in seating areas that transform retaining walls into functional gathering spaces—perfect for those summer evenings in your Woburn backyard.

Plantable wall systems that incorporate greenery are gaining popularity for their softer appearance and environmental benefits. Many homeowners are choosing contrasting cap colors to create visual definition, while curved designs that follow natural landscape contours create a more organic feel than traditional straight walls.

Thoughtful lighting integration transforms your wall from daytime workhorse to nighttime showpiece. Cap lights provide subtle pathway illumination for safety, while recessed fixtures create dramatic wall-washing effects. Many of our clients are choosing solar options for energy efficiency or smart lighting systems that can be programmed through their phones.

To truly maximize your investment, consider complementary features like integrated steps between levels, water features built into the wall face, or matching columns that define entry points. For more inspiration, browse our gallery of Retaining Walls Ideas showcasing projects we’ve completed throughout Woburn, Winchester, Burlington, and other Massachusetts communities.

Conclusion

A well-executed block retaining wall design does more than just solve a slope problem—it creates valuable outdoor living space while providing crucial structural support and protecting against erosion. Throughout this guide, we’ve explored the essential components that make retaining walls successful and long-lasting.

The foundation of any great wall begins with understanding the engineering principles that keep it standing strong year after year. From proper base preparation to effective drainage systems, each element plays a vital role in creating a structure that will withstand New England’s challenging climate.

Remember these five cornerstones of retaining wall success:

Proper base preparation and embedment ensures your wall starts on solid footing, quite literally. Those first few inches below grade might be invisible once your project is complete, but they’re doing the heavy lifting when it comes to stability.

Effective drainage systems prevent the silent enemy of retaining walls—water pressure—from building up behind your structure. That simple perforated pipe and clean stone combination can mean the difference between a wall that lasts decades and one that fails prematurely.

Appropriate reinforcement transforms a simple stack of blocks into an engineered system capable of holding back tons of soil. For walls over four feet, geogrid isn’t just recommended—it’s essential.

Professional engineering provides peace of mind and code compliance. When your wall exceeds certain heights or supports additional loads, having an engineer’s stamp isn’t just smart—it’s often required by law.

Quality materials suited to our climate ensure your investment stands up to freeze-thaw cycles, heavy precipitation, and everything else Mother Nature throws at it here in Massachusetts.

At AJM Grounds, we bring decades of experience in block retaining wall design to every project we undertake in Woburn and surrounding communities. Our team understands the unique challenges of New England soils and weather patterns, ensuring your wall will remain beautiful and functional for generations.

Whether you’re looking to create a simple garden wall to define a planting bed or need a complex engineered system for a challenging hillside, we’re here to help. Our design process begins with a thorough site evaluation, followed by detailed planning that considers both structural requirements and your aesthetic vision.

Ready to transform your sloped property into usable, beautiful outdoor space? Contact AJM Grounds today for a consultation, and let us show you how our attention to detail and personalized approach make all the difference in creating retaining walls that stand the test of time.

For more information about our retaining wall construction services, visit our retaining wall construction page.