Understanding Retaining Wall Basics: Function & Benefits

A block wall retaining wall is a structure built to hold back soil and prevent erosion on sloped terrain, typically constructed using concrete blocks designed specifically for retaining wall applications.

Quick Answer: Block Wall Retaining Wall Essentials

– Purpose: Holds back soil on slopes and prevents erosion

– Construction: Uses interlocking concrete blocks (5000+ PSI strength)

– Height Range: Typically 2-4 feet for DIY; professional installation for taller walls

– Key Components: Base, drainage system, backfill, blocks, and caps

– Cost: $20-75 per square foot (average internet prices; high-end installations can reach $200+ per square foot)

Block wall retaining walls serve both functional and aesthetic purposes in landscaping. They transform unusable sloped areas into flat, usable spaces while adding visual appeal to your property.

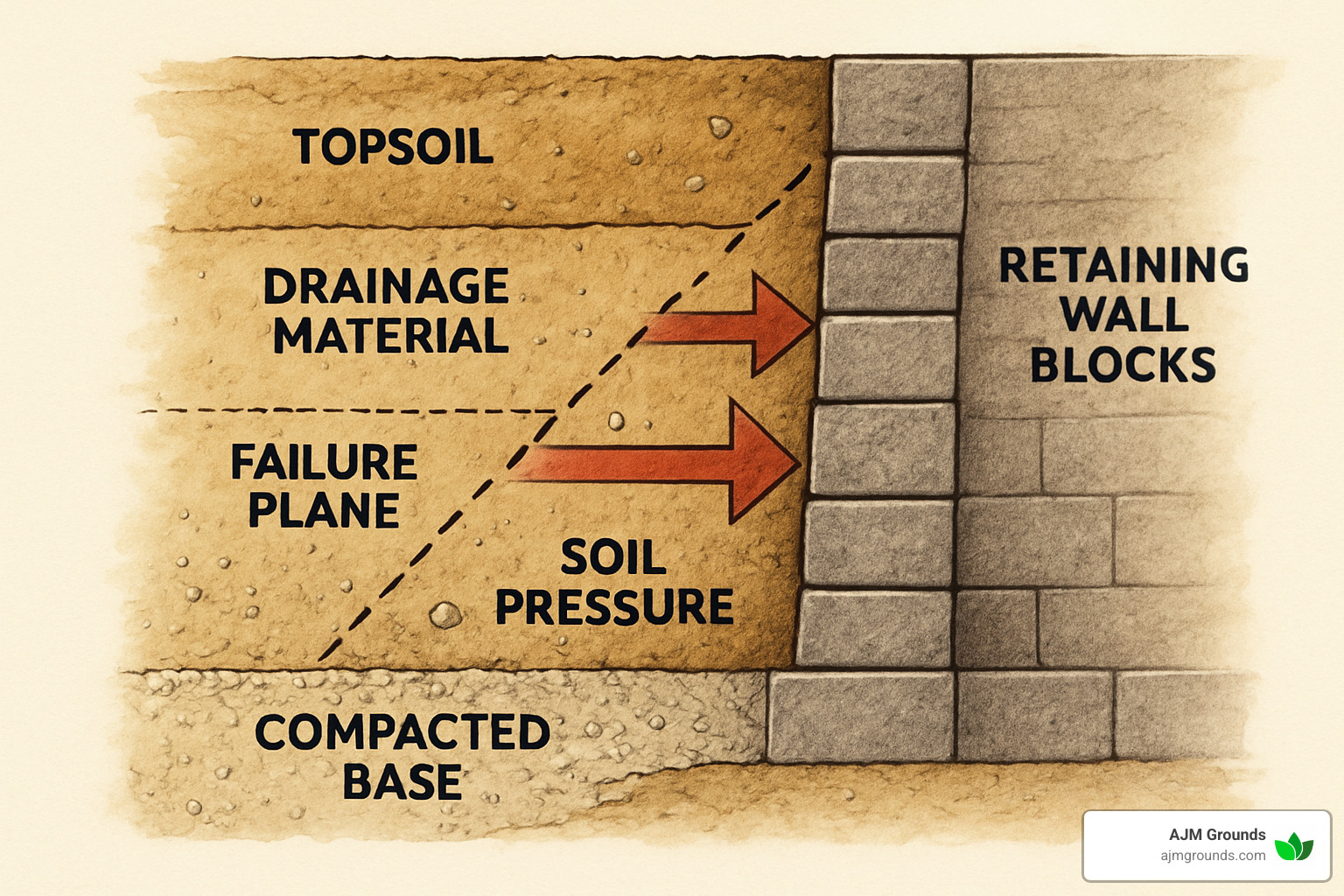

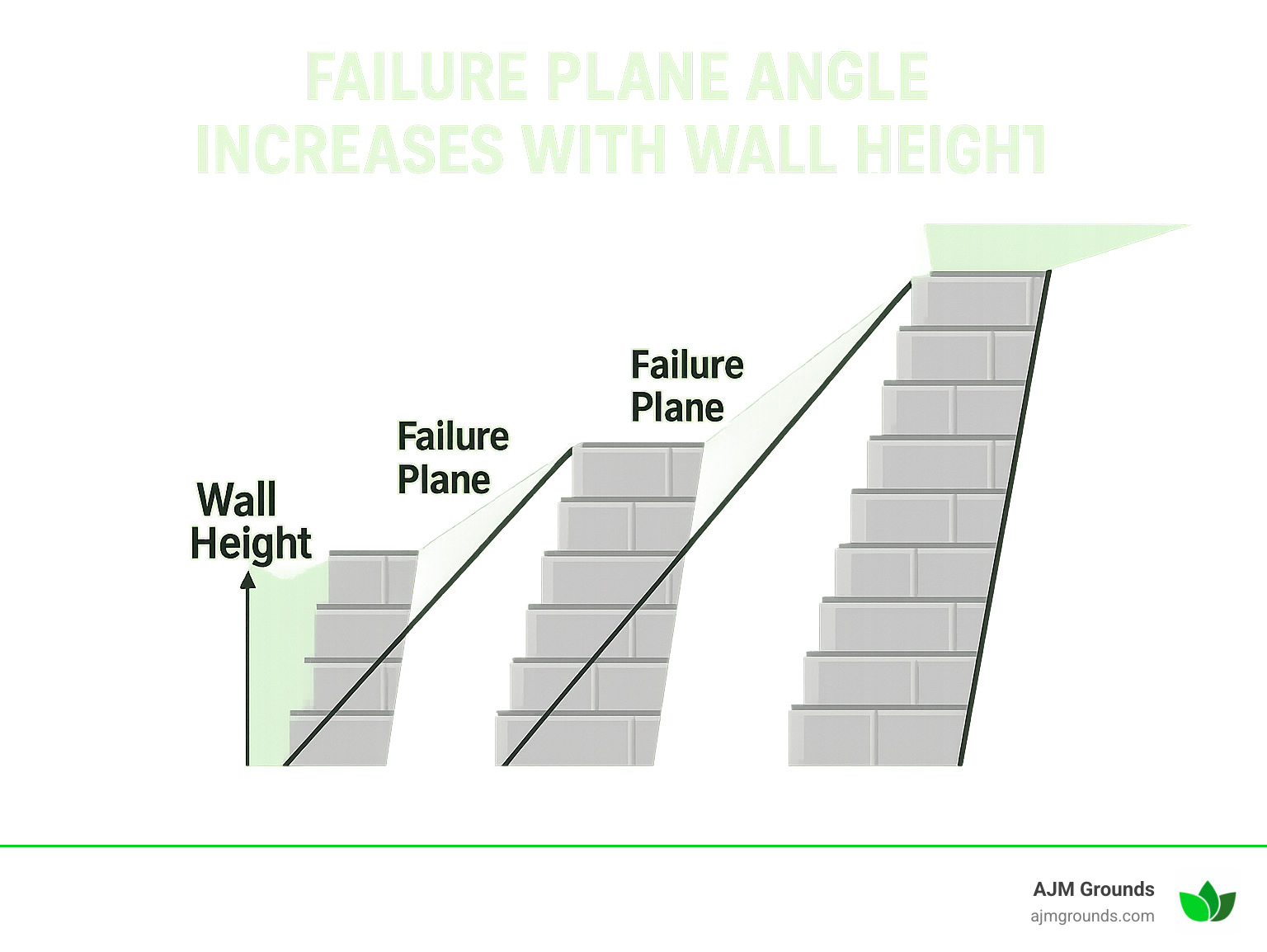

Unlike freestanding decorative walls, retaining walls must be engineered to withstand significant lateral pressure from the soil they hold back. This pressure increases with wall height and soil moisture content, making proper design and construction essential.

As the homeowner, you might be considering a block wall retaining wall to:

- Prevent soil erosion on your property

- Create level areas for gardens, patios, or play spaces

- Add architectural interest to your landscape

- Increase your property’s usable outdoor space

- Define different zones in your yard

I’m John Caplis, owner of AJM Grounds LLC, and I’ve installed hundreds of block wall retaining walls throughout Woburn and Greater Boston, designing each structure to withstand New England’s challenging weather conditions while enhancing property aesthetics and functionality.

Simple block wall retaining wall glossary:

– concrete retaining wall builders

– retaining wall builders near me

– retaining walls ideas

What Is a Block Wall Retaining Wall?

A block wall retaining wall is a structure designed to resist the lateral pressure of soil when there’s a desired change in ground elevation. Unlike decorative walls, retaining walls must withstand the tremendous pressure exerted by soil and water behind them.

The principle behind a block wall retaining wall is surprisingly simple: the wall uses its weight and setback (slight backward lean) to counteract the natural tendency of soil to move downhill. Think of it as an engineered barrier that holds back a “wedge” of soil that would otherwise slide down a slope.

You might not realize it, but soil is incredibly heavy—weighing over 100 pounds per cubic foot—and constantly pushing against anything holding it back. This is why your block wall retaining wall needs to be properly built to serve its primary functions:

Block wall retaining walls do more than just look nice. They prevent erosion on slopes, create usable flat spaces in your yard, provide structural support for liftd areas like driveways, manage water runoff, and add beautiful definition to your landscape.

How a block wall retaining wall works

Your block wall retaining wall stands strong against soil pressure through several clever engineering features:

The weight of the concrete blocks themselves creates a sturdy counterforce against soil pressure. At AJM Grounds, we use premium blocks engineered with at least 5000 PSI compressive strength—perfect for withstanding our harsh New England freeze/thaw cycles.

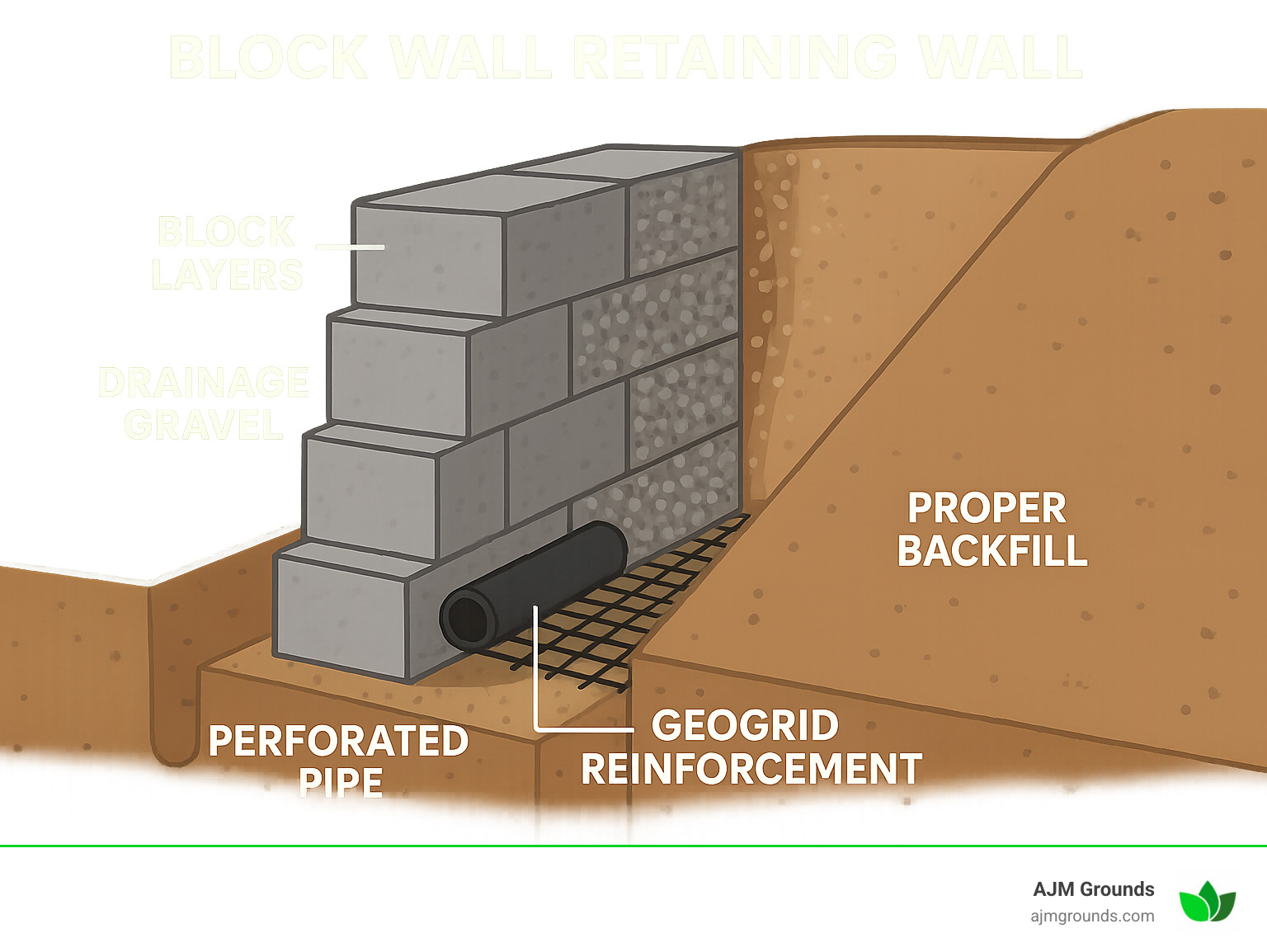

Each row of blocks sits slightly back from the row below (typically about 3/4″), creating a lean into the hillside. This seemingly small detail makes a huge difference, as it uses the soil’s own weight to help support the wall rather than push against it.

Behind the wall, a layer of 3/4″ crushed stone allows water to flow freely downward instead of building up pressure. Many homeowners don’t realize that trapped water (not the soil itself) is actually the number one cause of retaining wall failures.

At the base, a perforated drainage pipe collects this water and directs it safely away from your wall. For larger walls over 4 feet tall, these pipes should vent to daylight every 50 feet to ensure proper drainage.

Here in Massachusetts, where winter can be brutal, these drainage elements become even more critical. When water freezes behind a wall, it expands with tremendous force. At AJM Grounds, we design our drainage systems specifically for these regional challenges.

Freestanding vs. block wall retaining wall

Many of our Woburn and Greater Boston clients initially confuse freestanding walls with retaining walls. The difference is crucial for both safety and longevity of your landscape project.

Freestanding walls are primarily decorative features built on flat ground. They define spaces in your yard or add visual interest, but don’t need to resist significant lateral pressure. They can be thinner in profile and don’t require extensive drainage systems.

In contrast, block wall retaining walls are workhorses that hold back slopes and resist substantial lateral pressure. They need proper footings, excellent drainage, and often require geogrid reinforcement for taller applications. They must be built on a properly compacted base with a slight backward lean to counteract soil pressure.

In our years serving Bedford, Billerica, Burlington, and surrounding Massachusetts communities, we’ve seen many DIY projects fail because homeowners built a decorative wall when what they actually needed was a properly engineered retaining wall. The distinction isn’t just about aesthetics—it’s about creating a structure that will stand the test of time and our challenging New England seasons.

Types & Materials of Block Wall Retaining Walls

When it comes to block wall retaining walls, there’s quite a variety to choose from, and each option brings something special to the table. I’ve seen countless homeowners get overwhelmed by these choices, but understanding the basics can make your decision much easier.

Let’s talk about the materials you’ll most commonly encounter in your search. Segmental Retaining Wall (SRW) Blocks are probably what you picture when thinking about modern retaining walls. These interlocking concrete units stack without mortar and typically feature clever lip or pin systems that keep everything aligned. They’re perfect for DIY projects and walls up to about 4 feet high.

Then there are Concrete Masonry Units (CMU) – what many folks call cinder blocks. These traditional 8″ x 8″ x 16″ workhorses require mortar between courses and usually need vertical rebar reinforcement through their hollow cores, which then get filled with concrete. They’re incredibly sturdy but require more technical know-how to install properly.

For larger commercial projects or substantial residential needs, Large Precast Concrete Blocks might be the answer. These behemoths can weigh up to 2 tons each and create what we call “gravity walls” – structures that rely purely on their massive weight for stability. When I see these installed, I’m always impressed by their sheer presence in the landscape.

If aesthetics are a priority (and they usually are!), Split-Face Blocks offer a beautiful textured, stone-like appearance while maintaining structural integrity. No need for additional veneer when you’ve got these beauties doing the heavy lifting. For a more contemporary look, Ground-Face Blocks provide a sophisticated, polished granite-like finish that works wonderfully in modern landscape designs.

What makes these materials so suitable for New England’s tough weather? Premium blocks are manufactured to exceed industry standards with a minimum compressive strength of 5000 PSI, giving them exceptional resistance to our notorious freeze/thaw cycles. After seeing countless walls withstand decades of harsh Massachusetts winters, I can attest to their durability.

Common block wall retaining wall systems

The structural approach to your block wall retaining wall will largely depend on its height and the specific challenges of your site.

Gravity Walls are the simplest system, relying on the weight of the blocks and their setback (that slight backward lean) to resist soil pressure. They work beautifully for walls up to about 4 feet tall in most residential settings. We typically build these with approximately 1″ of setback for every 8″ of height – this seemingly small adjustment makes a huge difference in stability.

For taller applications, Reinforced Soil Walls incorporate geogrid – a synthetic mesh that extends back into the soil between layers of blocks. This clever system creates a reinforced soil mass that works together with the wall. I’m always amazed that properly reinforced segmental walls can reach heights exceeding 50 feet when engineered correctly!

Some situations call for Hybrid Anchor Systems that combine block weight with mechanical anchors tied back into the soil. These provide additional resistance against lateral pressure and are especially useful in challenging sites with limited space for geogrid reinforcement.

When a smooth face is desired or when integrating with other masonry elements, Mortared Block Walls using traditional CMU construction offer great versatility. The mortar between blocks and vertical rebar reinforcement create a unified structure with excellent strength.

Throughout our years serving Lexington, Reading, Stoneham, and other Massachusetts communities, we’ve installed all these systems, carefully selecting the appropriate approach based on site conditions, height requirements, and the aesthetic vision of the homeowner.

Choosing the right blocks & accessories

Selecting the perfect blocks and accessories for your block wall retaining wall isn’t just about looks – though that’s certainly important! It’s about creating a system that works harmoniously for decades to come.

Block size matters more than you might think. Larger blocks generally create stronger walls but often require equipment for placement. Smaller blocks offer greater design flexibility and are easier to handle manually – perfect if you’re considering a DIY approach or if site access is limited.

The connection system between blocks is crucial for long-term stability. Look for blocks with effective interlocking mechanisms like rear lip systems that automatically create the proper setback, pin connection systems that lock blocks together, or tongue-and-groove designs that ensure perfect alignment. These seemingly small details make a massive difference in wall performance.

Don’t forget the finishing touches! Capstones create a polished look while protecting the top of your wall from water infiltration. We typically secure these with high-quality masonry adhesive for a permanent bond. They’re like the crown on your wall’s head – both protective and decorative.

For walls over 4 feet tall, geogrid reinforcement becomes essential. The specific grade and length required will depend on your wall’s height, soil conditions, and any additional loads. This synthetic mesh creates a reinforced soil mass that dramatically increases stability.

To maintain proper drainage (the lifeblood of any retaining wall), filter fabric prevents fine soil particles from washing into your drainage aggregate. Paired with clean 3/4″ crushed stone (not rounded pea gravel) and a 4″ perforated pipe, you’ve got a drainage system that will keep water moving away from your wall rather than pushing against it.

When we design retaining walls for our clients in Wilmington, Winchester, Woburn, and beyond, we carefully balance structural requirements with aesthetic considerations, creating walls that not only stand the test of time but also improve the overall landscape design.

More info about block wall installation

Designing & Planning Your Retaining Wall

Planning a block wall retaining wall is a bit like preparing for a home renovation – the more thorough your preparation, the smoother your project will go. This planning phase isn’t just about aesthetics; it’s about creating a structure that will stand strong for decades.

When I meet with homeowners in Woburn and surrounding communities, I always emphasize that proper design prevents future headaches. Let’s walk through what you’ll need to consider before breaking ground.

Height and Load Considerations

The height of your wall is probably the single most important factor in determining how complex your project will be. Here’s what you need to know:

Walls under 4 feet tall (including the portion below ground) are generally DIY-friendly and typically don’t require engineering approval. For walls over 4 feet, you’ll likely need a building permit and professional engineering plans. If you’re a weekend warrior looking to tackle this yourself, I’d recommend sticking to walls 3 feet or shorter for your first project.

But height isn’t the whole story. Your wall might face additional challenges like surcharge loads – that’s any extra weight sitting above your wall, like a driveway or patio. Even a relatively short wall supporting a driveway needs more reinforcement than a taller freestanding wall.

Other factors that affect your design include the slope above the wall (steeper slopes create more pressure), your soil type (clay soils hold more water and push harder against walls), and the frost depth in your area. Here in New England, we need to place footings below the frost line – typically about 4 feet deep – to prevent seasonal heaving.

Site Analysis and Preparation

Before you even purchase your first block, take time to understand your site. This groundwork (pun intended!) will save you time and money down the road.

Start with a soil test to determine what you’re working with. Sandy soils drain well but might not be as stable, while clay soils are stable but hold water that creates pressure. Next, always call 811 to mark underground utilities before digging – this free service can prevent dangerous and costly accidents.

Be sure to check your property boundaries too. Nothing’s worse than building a beautiful wall only to find it’s on your neighbor’s property! Also take note of how water currently moves across your property – your wall will change these patterns, and you’ll need to plan accordingly.

Finally, consider how materials will reach your construction site. Those pallets of blocks are heavy, and you’ll need a plan to get them where they need to go without tearing up your lawn or landscaping.

Engineering and Code Compliance

For taller walls or those supporting structures, professional engineering isn’t just recommended – it’s essential. An engineer will calculate soil pressure and determine appropriate reinforcement to ensure your wall stands the test of time.

Many Massachusetts communities have specific regulations for retaining walls, especially in areas with significant grade changes. At AJM Grounds, we’re familiar with local requirements throughout Bedford, Billerica, and surrounding areas, ensuring our projects meet or exceed all code requirements.

Building a landscape retaining wall

Drainage essentials to prevent wall failure

If there’s one thing I’ve learned after building hundreds of retaining walls, it’s that water is your wall’s worst enemy. In fact, poor drainage is the number one reason retaining walls fail. Water trapped behind a wall creates enormous pressure – enough to push over even well-built structures.

A proper drainage system starts with clean 3/4″ crushed stone behind the wall. This creates a drainage zone at least 12 inches wide where water can flow freely downward instead of pushing against your wall. Don’t substitute rounded pea gravel here – it won’t provide the stability needed.

At the base of your wall, install a 4-inch perforated drain pipe wrapped in filter fabric. This pipe should run the entire length of the wall and slope slightly to direct water away. For walls over 4 feet tall, this pipe should vent to daylight every 50 feet or connect to a storm drain system.

Filter fabric is another essential component, placed between the drainage gravel and backfill soil. This prevents fine soil particles from washing into and clogging your drainage system – think of it as a coffee filter for your wall.

Don’t forget about surface water either. The soil at the top of your wall should be graded to direct water away, not toward the wall. In some cases, adding an 8-12 inch layer of compacted clay soil at the top creates an impervious cap that helps shed water away from your drainage system.

Latest research on drainage details

Estimating materials & average price ranges

Getting your materials estimate right will save you from making multiple trips to the supply yard or overspending on unused materials.

For block calculation, measure your wall’s length and height in feet, then multiply to find the square footage of the wall face. Check your block manufacturer’s specifications to determine how many blocks you’ll need per square foot, then multiply. Always add about 10% extra for cuts, breakage, and design features – trust me, you’ll use them!

Your base material calculation starts with your trench dimensions. Multiply length × width × depth to find the volume in cubic feet, then convert to tons (divide by 27 cubic feet per cubic yard, then multiply by 1.5 tons per cubic yard).

For drainage gravel, calculate the volume (wall length × drainage width × wall height) and convert to tons using the same method.

If your wall needs geogrid reinforcement, the amount depends on your wall height and manufacturer specifications. Typically, geogrid extends back from the wall a distance equal to 60-70% of the wall height.

As for costs, block wall retaining walls vary widely in price based on materials, complexity, and location. Based on internet data (not AJM Grounds pricing), DIY block retaining walls typically range from $20-40 per square foot. Professional installation generally runs $40-75 per square foot, while high-end custom installations can range from $75-200+ per square foot.

These costs fluctuate based on block type and quality, wall height and complexity, site accessibility, soil conditions, and local labor rates. For our clients throughout Burlington, Lexington, and other communities we serve, we provide detailed estimates that account for all these factors.

More info about block retaining wall design

Step-by-Step Guide to Building a Block Wall Retaining Wall

Building a block wall retaining wall is like putting together a puzzle that needs to last for decades. It’s a project that rewards careful attention to detail and proper technique. Let me walk you through how we approach these projects at AJM Grounds:

1. Site Layout and Preparation

Before the first shovel hits the ground, proper planning sets the stage for success. We start by marking the wall’s exact location using stakes, string, and marking paint to visualize the finished project.

Safety comes first, so we always call 811 to identify underground utilities before digging. This free service can save you from dangerous and costly mistakes. Next, we clear away all vegetation, topsoil, and organic material from the wall area – these materials decompose over time and would cause settling.

The ground around your future wall should be graded to direct water away, not toward it. Water is the number one enemy of retaining walls, so we address drainage from day one.

2. Excavation and Base Preparation

A solid foundation is crucial for any block wall retaining wall. We dig a trench approximately 24 inches wide (or twice the width of your blocks) and at least 6 inches deep, plus an additional inch for every foot of planned wall height. For walls exceeding 4 feet, the base must extend below the frost line – about 4 feet deep in most New England locations.

After removing any soft spots in the soil, we add 6 inches of 3/4-inch crushed stone and compact it thoroughly with a plate compactor, making at least two passes. This base must be perfectly level in all directions – any imperfections here will be magnified as the wall rises.

3. Installing the First Course

The first course is the most critical part of your block wall retaining wall. We start by spreading a thin layer of coarse sand or 1/4-inch minus gravel as a leveling bed. The first block goes at the lowest point of the wall, and we check it with a level in both directions.

Each subsequent block is placed tight against its neighbor, checking level and alignment continuously. A string line helps ensure perfect alignment across the entire length. For walls up to 3 feet tall, we typically bury about half of this first course to provide stability and a finished look.

4. Drainage System Installation

Proper drainage prevents wall failure. We place filter fabric against the excavated soil behind the wall, then install a 4-inch perforated drain pipe at the base. This pipe gets surrounded with clean 3/4-inch crushed stone and slopes away from the wall (about 1/4-inch drop per foot) to carry water away.

For longer walls, we ensure the pipe either daylights (exits visibly) at the end of the wall or connects to an existing drainage system. This seemingly small detail prevents thousands of dollars in potential damage.

5. Building Subsequent Courses

As we build upward, we sweep the top of each course clean before adding the next layer. Proper staggering of joints (like brick work) is essential – each joint should be offset by at least 1/4 of a block length from the course below.

Each new course needs the manufacturer’s specified setback – usually about 3/4-inch – which creates that slight backward lean that helps the wall resist soil pressure. We check level and alignment frequently, making adjustments as needed. When blocks need cutting, we use a masonry saw with a diamond blade for clean, precise cuts.

For taller walls, we add geogrid reinforcement at the specified heights, extending it back into the soil the proper distance.

6. Backfilling and Compaction

Proper backfilling is where many DIY projects go wrong. We add clean 3/4-inch crushed stone to create a drainage zone at least 12 inches wide behind the wall. Beyond this drainage zone, we use appropriate fill material – never organic or clay soils, which hold water and create pressure.

The secret to longevity is compacting in thin layers – never more than 6-8 inches at a time – using a plate compactor. Heavy equipment stays at least 3 feet away from the wall to avoid pushing blocks out of alignment. The final grade always slopes away from the wall to direct surface water elsewhere.

7. Finishing Touches

The wall caps are secured with masonry adhesive for a finished look that won’t shift over time. We backfill the final grade with topsoil and often add plants or mulch to improve the appearance, being careful to avoid deep-rooted plants near the wall that could cause issues later.

Many of our clients in Reading, Stoneham, and Wilmington opt to add landscape lighting to showcase their new wall at night – a beautiful touch that adds safety and extends outdoor enjoyment into the evening.

More info about retaining wall construction

DIY checklist for a block wall retaining wall

If you’re tackling a block wall retaining wall as a weekend warrior, preparation is key. You’ll need basic tools like a shovel, rake, wheelbarrow, tape measure, 4-foot level, string line, rubber mallet, and safety equipment. Don’t forget the plate compactor – this isn’t optional if you want your wall to last.

For materials, beyond the obvious retaining wall blocks and cap stones, you’ll need plenty of 3/4-inch crushed stone, perforated drainage pipe, filter fabric, and landscape adhesive. For walls over 3 feet, add geogrid to your shopping list.

Be realistic about your timeline. A small 20-foot by 3-foot wall might take 1-2 weekends, while larger projects can consume a month of weekends. And don’t go it alone – this is heavy work that’s much safer and more efficient with at least one strong helper. Pre-position your materials close to the work area to minimize carrying, and consider renting a power wheelbarrow for larger projects.

Walls over 4 feet tall should be designed by a professional engineer and typically require permits. Even shorter walls may need permits in many Massachusetts communities, so check with your local building department before starting.

Common mistakes to avoid

After building hundreds of block wall retaining walls throughout Winchester, Woburn, and beyond, I’ve seen the same mistakes trip up DIYers time and again.

Skimping on the base is like building a house on sand – it simply won’t last. Always use a full 6 inches of compacted crushed stone. Similarly, poor drainage is the number one cause of wall failure. That drainage gravel and perforated pipe might seem like optional extras when you’re on a budget, but they’re absolutely essential.

Inadequate compaction of your backfill material is another common pitfall. Each layer must be thoroughly compacted in thin lifts, and sorry, but a hand tamper just won’t cut it – rent a plate compactor.

Many DIYers create walls with aligned vertical seams rather than properly staggered joints, creating weak points throughout the structure. And using the wrong backfill material – like the soil you just excavated – can trap water behind the wall and lead to failure.

Always follow the manufacturer’s specifications for your particular block system. Each has specific requirements for setback, reinforcement, and maximum height. And speaking of height, building too high without reinforcement is asking for trouble – walls over 3-4 feet typically need geogrid and engineering review.

Don’t forget the filter fabric behind your drainage stone – without it, soil particles will eventually clog your drainage system. And those decorative caps should be secured with landscape adhesive to prevent shifting and create a finished look.

Correcting these mistakes after construction is far more expensive than doing it right the first time. Trust me, I’ve seen the aftermath!

More info about retaining wall repairs

Costs, Maintenance & Design Ideas

When you’re considering a block wall retaining wall, understanding what affects costs, how to maintain your investment, and the creative possibilities can help you make smarter decisions for your property.

Cost Factors

The price tag of a block wall retaining wall varies widely based on several key elements that we see regularly in our Woburn and Greater Boston projects:

The biggest cost drivers include wall dimensions, block quality, and site conditions. A challenging hillside with poor access might double your costs compared to an easily accessible, gently sloped area. Similarly, choosing premium blocks with specialized textures or colors will increase material costs substantially.

Based on internet data (not AJM Grounds pricing), you can expect to pay anywhere from $20-40 per square foot for basic installations, $40-75 per square foot for mid-range projects with better materials, and $75-200+ per square foot for high-end custom work. These are market averages – your specific project might fall outside these ranges.

I’ve found that many homeowners don’t account for excavation costs, which can be substantial if heavy equipment access is limited. Similarly, specialty blocks like ground-face or large-format options look fantastic but command premium prices. When geogrid reinforcement becomes necessary (typically for taller walls), expect to add 15-30% to your material costs.

Curved designs, while visually striking, require more precise cutting and additional labor time. And don’t forget that integrated features like steps, lighting, or built-in seating areas – while absolutely worth it – will increase both complexity and cost.

Maintenance Requirements

One of the beauties of a properly built block wall retaining wall is its relatively low maintenance requirements. However, a little attention goes a long way toward maximizing lifespan:

During spring and fall, take a few minutes to inspect your wall for any signs of movement, bulging, or damage. Make sure drainage outlets remain clear – this is absolutely critical after winter in our New England climate, where freeze-thaw cycles can wreak havoc on improperly drained walls.

Once a year, clear away any debris that’s accumulated behind or around the wall. I always remind our clients in places like Lexington and Reading to be vigilant about deep-rooted plants – those innocent-looking tree seedlings can eventually create serious structural issues if allowed to grow too close to your wall.

Every 5-10 years, consider applying a quality sealer to protect your blocks from staining and extend their color vibrancy. This is also a good time to refresh any landscaping around the wall and address any minor settlement that may have occurred.

The good news? With proper installation and these simple maintenance steps, your block wall retaining wall can last 50-100+ years – a tremendous value compared to many other landscape investments.

Creative Design Ideas

A block wall retaining wall doesn’t have to be just functional – it can be a stunning focal point that transforms your outdoor space:

Some of our favorite functional design elements include built-in seating walls that create natural gathering spaces around patios or fire pits. Integrated steps provide neat access between levels, while raised planting beds add visual interest and gardening opportunities. We’ve even used block wall retaining walls as foundations for outdoor kitchens and to create beautiful pool deck surrounds.

For aesthetic appeal, consider mixing block sizes or incorporating subtle color variations. Curved walls often look more natural and inviting than straight lines, while terraced or tiered designs create opportunities for dramatic plantings. Strategic landscape lighting can transform your wall into a nighttime showpiece.

The latest trends we’re implementing throughout Burlington and Billerica include large-format blocks that create clean, modern lines with fewer visible seams. Dark-colored blocks make a bold contemporary statement, while walls with integrated planting pockets bring living greenery directly into the structure.

I particularly love designing multi-purpose walls that serve several functions simultaneously – perhaps a retaining wall that doubles as seating, incorporates subtle lighting, and includes a small water feature. These multi-function designs maximize your investment and create truly unique outdoor spaces.

More info about landscape retaining walls

Comparing block walls to timber, poured concrete & natural stone

When advising clients in Woburn and surrounding communities, I always present all the retaining wall material options, though block wall retaining walls often provide the best overall value:

| Feature | Block Wall | Timber | Poured Concrete | Natural Stone |

|---|---|---|---|---|

| Durability | 50-100+ years | 15-20 years | 50-100+ years | 100+ years |

| DIY Difficulty | Moderate | Easy | Difficult | Very difficult |

| Flexibility for Curves | Good | Limited | Limited | Excellent |

| Environmental Impact | Moderate | Higher (treated wood) | Higher | Lowest |

| Cost Range (Internet Data) | $20-200/sq ft | $15-60/sq ft | $30-150/sq ft | $25-250/sq ft |

| Maintenance | Low | High | Low | Low |

| Aesthetic Options | Many | Limited | Limited | Many |

| Installation Speed | Moderate | Fast | Slow | Very slow |

The advantages of block wall retaining walls are compelling. They strike that perfect balance between reasonable cost and impressive longevity. The modular nature means homeowners can tackle smaller projects themselves, while the vast array of colors, textures, and sizes allows for personalized designs that complement any home style.

Unlike poured concrete walls, most block systems don’t require mortar, simplifying installation. And compared to natural stone, the consistent sizing of manufactured blocks makes construction more predictable and typically faster.

The main drawbacks? Blocks are certainly heavier than timber, requiring more physical effort during installation. Some homeowners prefer the completely natural look of stone, though modern blocks have become remarkably realistic. And while the initial investment is higher than pressure-treated timber, the significantly longer lifespan makes blocks more economical in the long run.

For most of our clients throughout Winchester, Stoneham, and beyond, block wall retaining walls hit that sweet spot of aesthetic appeal, durability, and value that makes them our most frequently recommended option.

Frequently Asked Questions about Block Wall Retaining Walls

When do I need a permit or engineer?

I get this question all the time when talking with homeowners about their block wall retaining wall projects. The answer isn’t always straightforward, but I can offer some helpful guidelines based on our experience throughout Massachusetts.

For permits, the magic number is usually 4 feet. Most towns in our area require permits for any retaining wall taller than 4 feet, measured from the bottom of the footing to the top of the wall. But here’s where it gets tricky – some communities require permits for any retaining wall regardless of height. This is especially true if your wall will be near property lines or public sidewalks.

And don’t forget about those special situations! If your block wall retaining wall will support a driveway, patio, or building, you’ll almost certainly need a permit regardless of height. I’ve seen this catch many DIYers by surprise in Bedford and Burlington.

As for engineering requirements, the same 4-foot threshold generally applies. Walls exceeding this height typically need an engineered design created by a professional. But even shorter walls might need engineering if they’ll support significant weight (like that new driveway) or if you’re building on problematic soils. And those beautiful tiered walls? If the upper wall might influence the stability of the lower wall, you’ll definitely want an engineer’s input.

Having built retaining walls throughout Billerica, Burlington, and beyond, I can tell you that local requirements vary significantly. We’re familiar with the regulations in all the communities we serve and can guide you through the sometimes confusing permitting process.

If you’re tackling this as a DIY project, I strongly recommend a quick call to your local building department before purchasing materials. Requirements change periodically, and it’s much easier to get permits before construction than to deal with a violation notice later!

How many blocks and how much gravel will I need?

Calculating materials for your block wall retaining wall isn’t complicated once you know the formula. Let me walk you through it with some real-world examples.

For blocks, start by measuring your wall’s length and height in feet. Multiply these numbers to get your wall’s square footage. Next, check your block manufacturer’s specifications to see how many blocks cover one square foot. Divide your wall’s square footage by this number, then add about 10% extra for cuts and waste.

Let’s say you’re building a wall that’s 20 feet long and 3 feet high using blocks that each cover 0.5 square feet. Your wall area is 60 square feet (20 × 3). You’ll need about 120 blocks (60 ÷ 0.5), plus 12 extra for waste, bringing your total to 132 blocks.

For the base material, calculate your trench volume by multiplying length × width × depth. The width is typically 24 inches (or twice the block width), and depth is usually 6-8 inches. For our 20-foot wall example with a 24-inch wide, 6-inch deep base, you’d need about 20 cubic feet of material. This converts to roughly 0.74 cubic yards or about 1.1 tons of base gravel.

Don’t forget the drainage gravel! Calculate this volume by multiplying your wall’s length × drainage width (typically 12 inches) × wall height. For our 20 × 3 foot wall with a 12-inch drainage zone, you’d need about 60 cubic feet, or 2.22 cubic yards, which equals about 3.33 tons of drainage gravel.

When we prepare proposals for clients in Reading, Stoneham, and throughout our service area, we include detailed material calculations. This ensures you have exactly what you need without expensive overages or frustrating shortages that can delay your project.

What’s the best way to handle water behind the wall?

I can’t stress this enough: water management is the make-or-break factor for your block wall retaining wall. In my years of building walls throughout Woburn and surrounding towns, I’ve seen far too many DIY walls fail because of poor drainage. The good news? With the right approach, you can prevent these issues entirely.

Think of drainage in layers, starting from the top. First, always grade the soil at the top of your wall to direct water away from it. Even a slight slope makes a huge difference. If you’re dealing with a hillside, consider adding a shallow swale above your wall to intercept runoff before it reaches the wall. And don’t forget about roof water – make sure downspouts direct water away from your retaining wall area.

The internal drainage system is your wall’s best friend. Install at least 12 inches of clean 3/4″ crushed stone (not rounded pea gravel) behind the entire wall. This creates a drainage zone that allows water to flow freely to the bottom. Always place filter fabric between this stone and the backfill soil – it’s an inexpensive step that prevents fine soil particles from clogging your drainage system over time.

At the base of your wall, install a 4-inch perforated drain pipe surrounded by gravel and wrapped in filter fabric. This pipe should slope away from the wall (at least 1/4″ drop per foot) and have an outlet to daylight or connect to a storm drain system. For longer walls over 4 feet tall, provide outlets every 50 feet to ensure proper flow.

Your choice of backfill material matters tremendously. Use free-draining soil beyond the drainage stone and avoid clay soils that trap water. Whatever material you use, compact it in 6-8 inch lifts to prevent settling and water pooling.

For challenging sites in Winchester, Woburn, and throughout New England, we often employ advanced techniques like impermeable clay caps at the top or chimney drains for slopes with multiple water sources. Our philosophy is always to exceed minimum drainage requirements, building in redundancy for those inevitable heavy rain events and spring thaws that put so much pressure on retaining walls in our region.

Conclusion

A well-designed and properly constructed block wall retaining wall is more than just a functional structure—it’s an investment that transforms your property while providing lasting value through improved usability, improved curb appeal, and protection against erosion.

Throughout this guide, we’ve explored how these remarkable structures work to hold back tons of soil pressure, the various block systems available, and the critical design elements that ensure long-term success. From drainage details to step-by-step construction techniques, we’ve covered what makes these walls stand the test of time.

At AJM Grounds, we’ve seen how a thoughtfully designed retaining wall can completely revitalize a property. Whether it’s creating a usable patio space from a sloped backyard or adding architectural interest to a plain landscape, these walls combine beauty and function in a way few other landscape elements can.

New England’s challenging climate—with its freeze-thaw cycles, heavy precipitation, and temperature extremes—demands special consideration when building retaining walls. Our designs account for these regional factors, incorporating robust drainage systems and premium materials that withstand even the harshest Massachusetts winters.

If you’re considering adding a block wall retaining wall to your property, proper planning makes all the difference. Whether you’re tackling a DIY weekend project or seeking professional installation, the principles remain the same: solid base preparation, proper drainage, and attention to detail during construction.

For homeowners in Bedford, Billerica, Burlington, Lexington, Reading, Stoneham, Wilmington, Winchester, and Woburn, we’re here to help with:

- Personalized consultations to understand your specific needs

- Custom designs that complement your home’s architecture

- Quality materials and craftsmanship from experienced installers

- Clear communication throughout your project

- Ongoing support and maintenance advice

Don’t let that sloped area of your yard go to waste any longer. Transform it into beautiful, functional space with a block wall retaining wall that will serve your family for decades to come. We’d love to help bring your vision to life—just reach out for a friendly, no-pressure conversation about your project.

More info about our retaining wall construction services