Transform Your Property with Professional Block Wall Installation

Block wall installation is a versatile landscaping solution that combines functionality with aesthetic appeal. Whether you’re looking to prevent soil erosion, create level areas on a sloped property, or improve privacy, a properly installed block wall can solve multiple landscape challenges while adding value to your property.

Looking for block wall installation services? Here’s what you need to know:

- Professional installation typically costs $15-$45 per square foot based on internet averages

- DIY installation requires proper planning, equipment, and physical labor

- Standard block walls can last up to 80 years with proper installation and maintenance

- Permits are required for walls over 36 inches in height in most municipalities

- Proper drainage is the #1 factor in preventing wall failure

Block walls come in various styles including retaining walls, freestanding privacy walls, and decorative garden walls. The key to successful installation lies in proper planning, site preparation, and meticulous attention to the foundation and drainage systems.

I’m John Caplis, owner of AJM Grounds LLC, and I’ve overseen hundreds of block wall installation projects throughout the Greater Boston area, helping homeowners transform their outdoor spaces with durable, attractive solutions that stand the test of time.

Block wall installation vocab explained:

– retaining wall builders near me

– backyard retaining wall ideas

– retaining walls ideas

Why Choose a Block Wall? Durability, Design & ROI

A well-built block wall isn’t just a practical addition to your property—it’s an investment that delivers benefits for decades to come. If you’re considering upgrading your landscape in Bedford, Billerica, Burlington, or anywhere in our Massachusetts service area, here’s why block walls deserve your attention.

Block wall installation creates structures with impressive staying power. With a compressive strength of at least 1,900 psi, these walls stand strong against New England’s challenging weather conditions. Think about this: a properly installed block wall can last up to 80 years! That’s essentially a once-in-a-lifetime home improvement that continues serving your family for generations.

What makes block walls so versatile is how they solve multiple landscape challenges simultaneously. They serve as retaining walls that prevent soil erosion on sloped properties, privacy walls that create intimate outdoor living spaces, decorative elements that improve your landscape design, and even sound barriers that buffer noise from busy streets or neighbors.

For homeowners concerned about value, block walls deliver impressive returns on investment. Beyond solving practical problems, they significantly boost curb appeal and property marketability. Many of our clients in Winchester and Lexington have told us their block wall projects made a noticeable difference when selling their homes.

Unlike wood alternatives that rot, warp, and attract pests, block walls are virtually maintenance-free. They’re completely fire-resistant, stand up to frost without damage, and never need painting or staining. For our environmentally conscious clients in Reading and Stoneham, it’s worth noting that concrete blocks are made from natural materials and remain fully recyclable even after their lengthy lifespan.

Types of Block Walls at a Glance

Your specific needs and property conditions will determine which type of block wall works best for your project. Here’s a straightforward overview of the options we commonly install throughout Greater Boston:

- Gravity Walls: Perfect for garden borders and small grade changes under 4 feet tall, these walls use their own weight and a slight backward lean (setback) to hold back soil pressure. Ideal for simpler projects in Wilmington and Burlington yards.

- Reinforced Walls: When you need more height or have limited space, these walls incorporate geogrid (a synthetic mesh) extending into the soil behind the wall. Our Woburn and Winchester clients with significant elevation changes often benefit from this approach.

- Cantilevered Walls: These engineered structures use a concrete footing that extends under the retained soil, essentially using the soil’s weight as an anchor. They’re perfect space-savers for compact urban properties in Lexington and Reading.

- Free-standing Walls: Not designed to retain soil, these walls create privacy, block wind, or add decorative elements throughout landscapes in Stoneham and Billerica.

- Segmental Interlocking Walls: Using specially designed blocks with lips, pins, or other connecting features, these walls lock together without mortar for added stability. They’re our most popular option for DIY-friendly installations.

- Modular Systems: These pre-engineered wall systems come with specific installation guidelines and often include matching components like caps, corners, and steps for a cohesive look.

- Garden Walls: Low-height decorative walls (typically under 3 feet) that define planting areas, create raised beds, or add visual interest to Bedford and Burlington landscapes.

Whether you’re dealing with erosion issues, seeking more privacy, or simply wanting to improve your property’s beauty and value, a professionally installed block wall delivers durability, design flexibility, and lasting returns that few other landscape improvements can match.

How to Plan (and Budget) for Block Wall Installation

Planning your block wall installation is like creating a roadmap for success. After completing hundreds of projects across Bedford, Winchester, and surrounding communities, I’ve learned that proper preparation prevents the most common headaches homeowners face.

Start with Permits and Codes

Before you pick up a single block, understand what’s legally required. Throughout Massachusetts communities:

- Walls taller than 36 inches typically require a building permit

- Local building codes often specify foundation requirements based on our regional frost line

- Homeowner associations may have additional restrictions on height, appearance, and materials

I recommend contacting your local building department early in your planning process. Our AJM Grounds team regularly steers these requirements for clients throughout Woburn and surrounding towns, often handling the permit process for you.

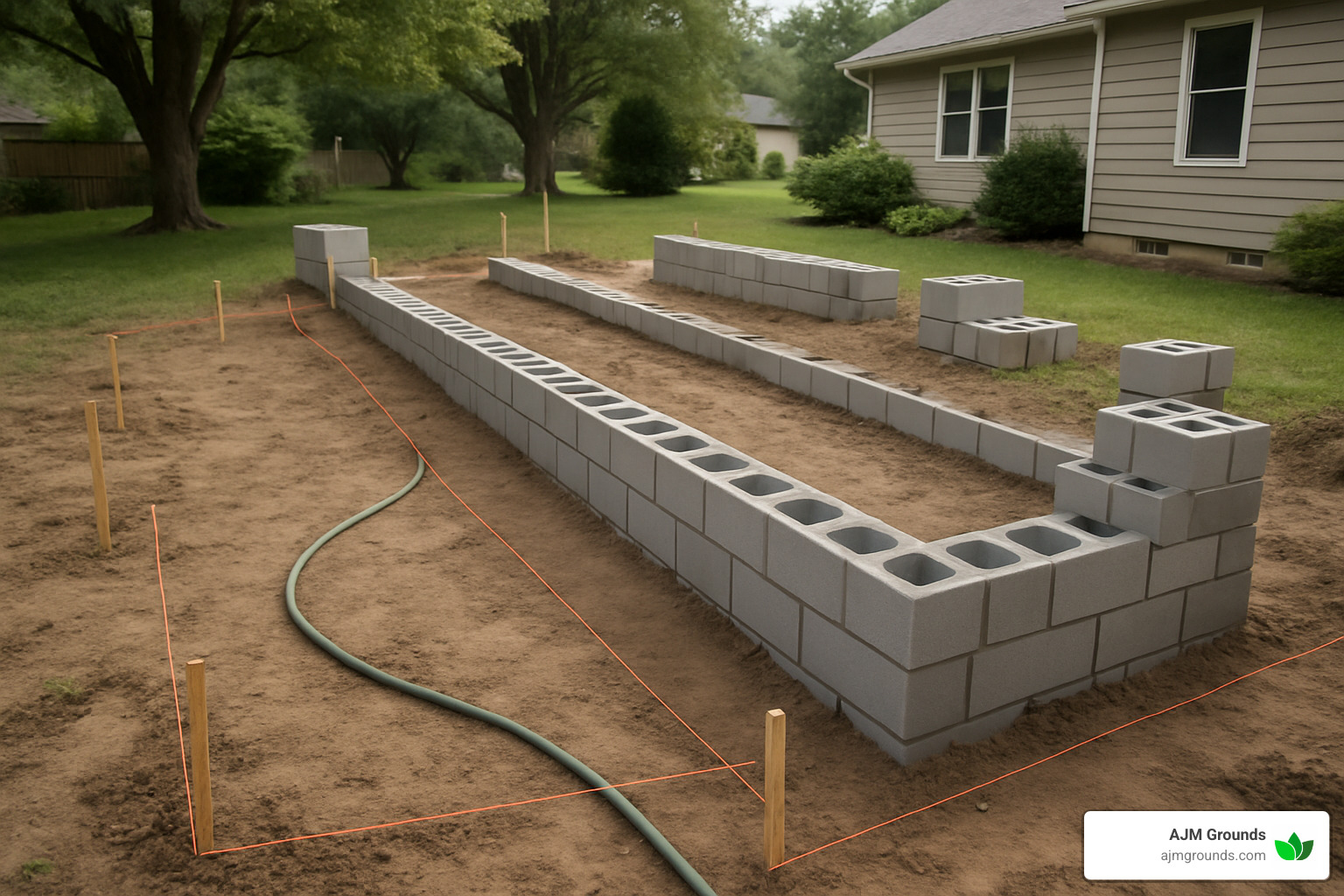

Site Assessment and Layout

A thorough evaluation of your property sets the stage for a successful block wall installation:

First, always call 811 at least 72 hours before digging to have underground utilities marked. This free service prevents dangerous and costly accidents. For larger walls, consider soil testing to determine proper reinforcement needs – the composition of your soil dramatically affects how your wall needs to be built.

Measuring the slope helps us determine precise wall height and drainage requirements. For the actual layout, we use stakes, mason’s line, and a line level to visualize the wall’s position. For curved walls, a simple garden hose works wonders for marking the desired shape before staking – this gives our Lexington and Reading clients a clear preview of their finished project.

Calculate Materials and Budget

Accurate estimation prevents those dreaded mid-project supply runs:

Standard 8×8×16 cinder blocks cover approximately 1.125 square feet each. Always add at least 10% extra to account for cuts, breakage, and future repairs. For mortar projects, one 80-pound bag typically lays about 12-14 standard blocks. Don’t forget to factor in base materials, drainage components, and finishing elements.

Based on internet averages (not AJM Grounds specific pricing), professional block wall installation typically costs between $15-$45 per square foot. However, real-world costs vary significantly depending on wall height, site accessibility, material choices, and local labor rates.

DIY vs. Professional Installation

Many of our Burlington and Bedford neighbors debate whether to tackle block wall installation themselves or hire professionals. Here’s a straightforward comparison:

| Factor | DIY Installation | Professional Installation (like AJM Grounds) |

|---|---|---|

| Cost | Lower initial expense but potential for costly mistakes | Higher upfront cost but includes expertise and warranty |

| Time | Extended timeline, often weekends and evenings | Typically completed in days rather than weeks |

| Equipment | Rental fees for specialized tools | Included in project cost |

| Quality | Depends on skill level and research | Consistent professional results |

| Permits | Homeowner responsibility | Often handled by contractor |

| Physical Labor | Significant – block walls are heavy work | Handled by trained crew |

| Warranty | None | Typically included |

Block Wall Installation Cost Breakdown

Understanding where your money goes helps with accurate budgeting. Based on publicly available internet data (not AJM Grounds specific pricing), here’s what typically contributes to block wall installation costs:

Block prices range from $2-$6 per block depending on style and material. Quality gravel base material costs between $30-$90 per cubic yard. Drainage components like perforated pipe and filter fabric typically run $0.50-$1.50 per foot. Permit fees vary widely from $50-$400 depending on your municipality and project scope.

If you’re going the DIY route, tool rental for compactors and cutting equipment adds approximately $60-$120 per day. Labor costs vary significantly by region and project complexity.

For a typical residential retaining wall, total project costs based on internet averages range from $2,500 for a small DIY project to $12,000+ for a larger professionally installed wall. Remember these are general ranges based on internet data – actual costs for your specific project in Woburn or Winchester may vary significantly.

Design Tools & Quantity Calculators

Today’s technology makes planning your block wall installation easier than ever:

Start with basic tools like stakes, mason’s line, wheel measure, and line level for layout. Many block manufacturers offer online calculators to help determine quantities needed for your specific project. Sketch apps provide simple design tools for visualizing your project, while more advanced 3D software options offer detailed visualization.

For more detailed information on designing your block wall, visit our page on Block Retaining Wall Design.

With careful planning and proper budgeting, your block wall project can transform your property while avoiding costly surprises along the way. Whether you choose DIY or professional installation, taking the time to plan thoroughly is always your best first step.

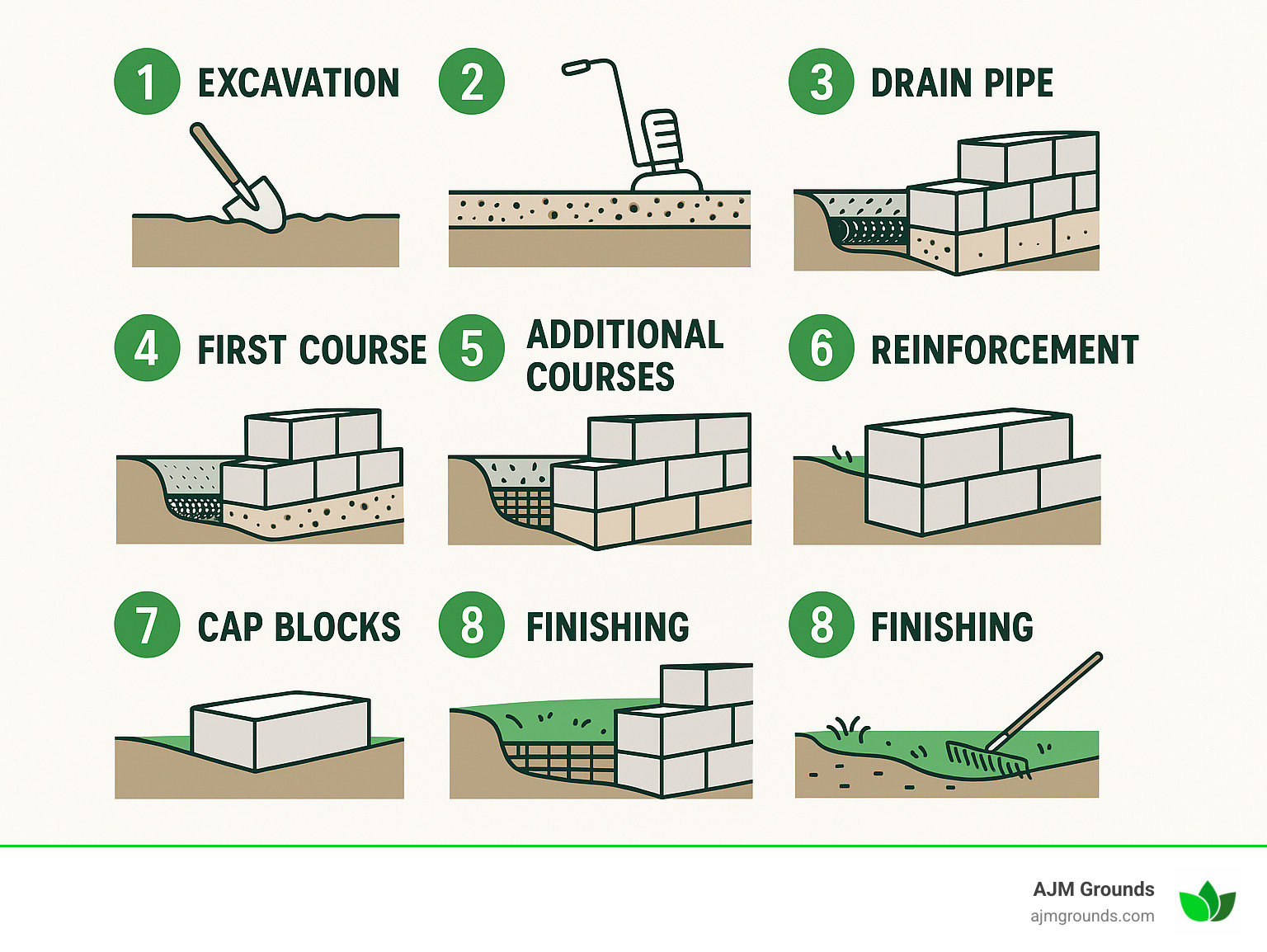

Block Wall Installation Checklist (Get It Right the First Time)

After installing countless block walls throughout Woburn, Winchester, Lexington, and neighboring towns, I’ve seen what makes the difference between a wall that lasts for decades and one that fails prematurely. Whether you’re planning to hire professionals or roll up your sleeves for a DIY project, understanding these critical steps will help ensure your wall stands the test of time.

Site Preparation

The foundation of any successful block wall installation begins with proper site prep. Start by clearing all vegetation and organic material from your installation area – those roots might seem harmless now, but they can cause serious problems later!

Excavation depth matters tremendously. As a rule of thumb, dig down at least 6 inches plus an additional inch for every foot of planned wall height. Your trench should be approximately 24 inches wide for standard walls (though 18 inches is sufficient for walls under 4 feet tall).

If you encounter unsuitable soil during excavation – like soft clay or organic material – don’t ignore it! These poor soils need to be removed and replaced with proper compactable material. Skipping this step is like building on quicksand.

Base Preparation

Think of your base as the foundation of your home – it simply must be right. Begin by lining your trench with landscape fabric, which prevents soil from migrating into your drainage zone (a common cause of wall failure).

Next, add a full 6 inches of ¾-inch crushed stone as your base material. Notice I specified crushed stone – rounded pea gravel won’t lock together properly and can shift over time. This is one detail where cutting corners will cost you later.

Compaction is critical! Use a plate compactor to make at least two passes over your base material. You want it firm enough that walking on it barely leaves footprints. Finally, check the level across your entire base length using grade pipes and string – this tedious step pays dividends in the final appearance.

First Course Installation

Your first course sets the stage for everything that follows. Place your blocks carefully on the prepared base, checking each one for level both front-to-back and side-to-side. A string line along the front of your blocks will help ensure perfect alignment – trust me, any wobbles or misalignments here will be magnified as you build upward.

For stability, half-bury your first course – at minimum, 6 inches or 10% of your total wall height should be below grade. This buried portion provides crucial resistance against the forces that will try to push your wall forward over time.

Drainage System

If there’s one thing I’ve learned from repairing failed walls throughout Bedford and Burlington, it’s that proper drainage is non-negotiable. Install a perforated drainage pipe behind your first course, positioned with at least a 2% slope to carry water away from the wall.

Always wrap your pipe in a filter sock or landscape fabric to prevent clogging. And don’t forget to vent the pipe to daylight every 50 feet so water has somewhere to go. A drainage system that can’t discharge water is like a bathtub without a drain!

Stacking Additional Courses

Before adding each new course, take a moment to brush off the tops of your blocks – even small debris can throw off your wall’s alignment. As you build upward, stagger your vertical joints by at least ¼ block length between courses to create a stronger structure.

For gravity walls, maintain the proper setback (typically ½ inch per course) to give your wall that slight lean-back that helps it resist pressure. Check level and alignment frequently – small errors compound quickly!

Backfill with ¾-inch crushed stone at least 12 inches behind the wall as you go, compacting in 8-inch lifts. Proper compaction prevents settlement that could otherwise cause your wall to lean forward over time.

Reinforcement (for Taller Walls)

For walls over 3 feet tall, geogrid reinforcement becomes essential. Cut your geogrid to the specified length and place it perpendicular to the wall, securing it by placing the next course of blocks on top. The geogrid should extend into the soil mass behind the wall according to your design specifications – typically at least 3 feet for residential applications.

Finishing Touches

Cap blocks not only give your wall a finished look but also provide additional stability. Secure them with concrete adhesive designed specifically for segmental retaining walls (SRW). Then backfill the top course with topsoil to support any planned plantings.

Grade the soil to slope away from your wall, creating yet another layer of drainage protection. Finally, clean the face of your wall to remove any soil or construction debris, revealing the beautiful hardscape you’ve created.

For more detailed guidance on base installation techniques, I recommend checking out this resource on retaining wall base installation.

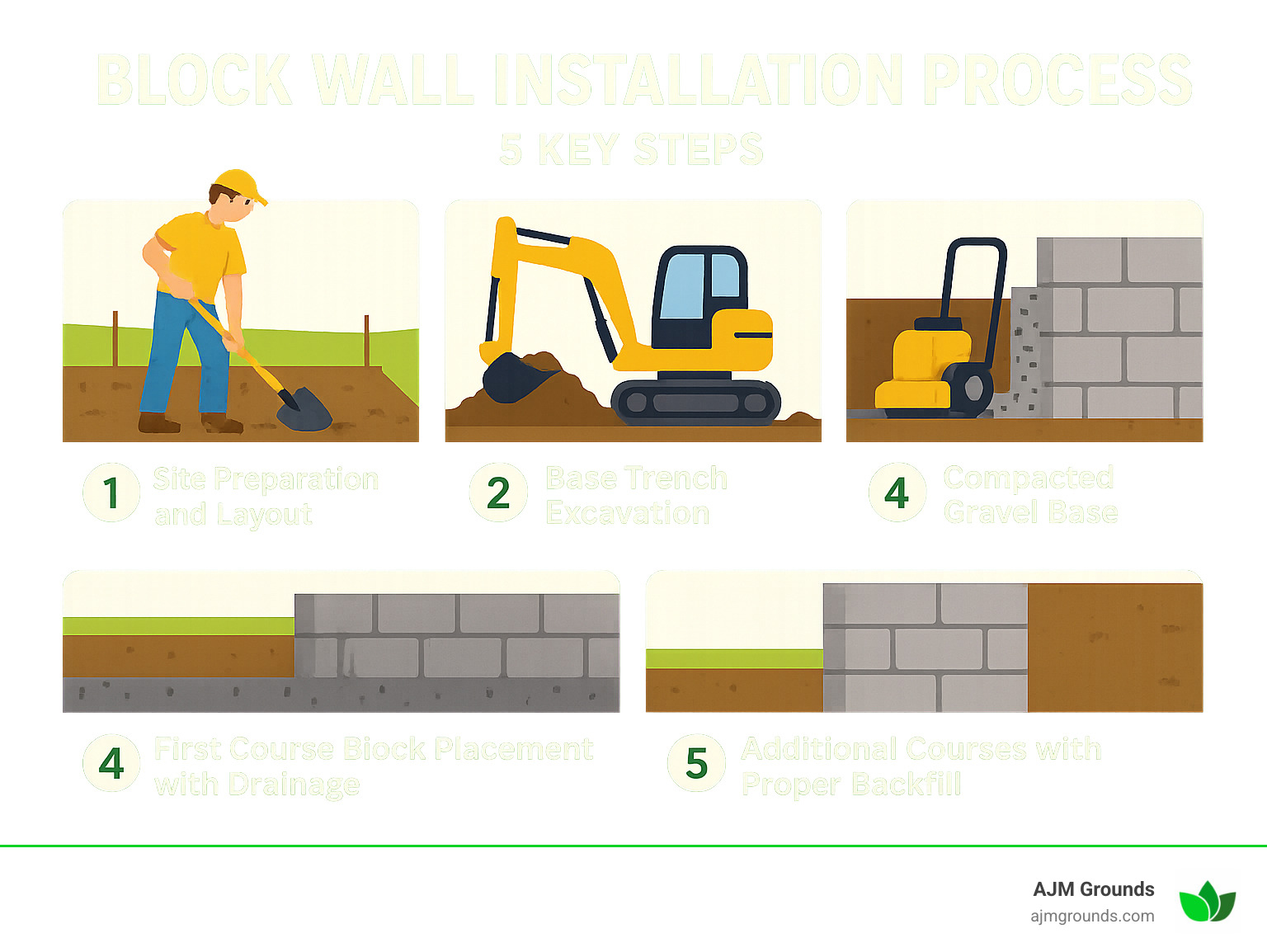

Block Wall Installation Steps in a Nutshell

If you prefer a simplified overview, here’s the block wall installation process in eight essential steps:

- Site Preparation: Mark layout, remove vegetation, and call 811 for utility marking

- Base Preparation: Excavate trench, add and compact gravel base

- First Course: Lay and level first row of blocks, partially buried for stability

- Drainage Installation: Add perforated pipe and drainage material behind the wall

- Stacking: Build subsequent courses with proper alignment and setback

- Cutting Blocks: Modify blocks as needed for corners, curves, and end pieces

- Backfilling: Add drainage material and compact in lifts as you build

- Capping and Finishing: Install cap stones, final grading, and cleanup

Common Mistakes & Safety Tips

After building hundreds of block walls in communities like Reading, Stoneham, and Wilmington, I’ve witnessed the consequences of common installation mistakes firsthand.

An uncompacted base inevitably leads to settling and wall failure – sometimes within the first year. Inadequate drainage remains the #1 cause of retaining wall failures I see throughout Massachusetts. Using soil instead of proper drainage stone behind the wall is another frequent error that traps water and creates massive pressure.

Many DIYers forget the critical setback that gives walls their stability. Walls built perfectly vertical are far more likely to tip forward over time. Misaligned courses not only look unprofessional but create structural weak points. And I’ve seen too many homeowners rush installation during bad weather – working in wet conditions almost always compromises proper installation.

Safety should never be an afterthought when working with heavy materials. Proper lifting technique – bending at the knees, not the waist – prevents painful back injuries. Don’t hesitate to use mechanical assistance like block dollies or ask for help with heavier units. Always wear personal protective equipment including gloves, safety glasses, and dust masks when cutting blocks.

Be aware of weather conditions – avoid working in extreme heat or on wet, slippery surfaces. And always follow manufacturer guidelines for power tools and compaction equipment.

If you’re dealing with an existing wall that’s showing signs of trouble, visit our page on Retaining Wall Repairs for expert advice on fixing common problems.

Product Roundup: Top Block Wall Systems & Accessories

After installing countless block walls across Woburn, Winchester, Lexington, and nearby towns, we’ve developed some strong opinions about which products deliver the best results for Massachusetts homeowners. Let me share what we’ve learned about the systems that stand up to our challenging New England conditions.

Interlocking Block Systems

The evolution of interlocking blocks has been a game-changer for block wall installation. These innovative systems have simplified the process while often eliminating the need for mortar completely.

Most modern systems feature clever design elements like pin systems with fiberglass or plastic pins that slide through holes for perfect alignment. Others use lip-and-groove units with a rear lip that automatically creates the proper setback as you stack. My personal favorites are the tongue-and-groove designs that lock together for impressive stability right from the start.

While these systems are marketed as DIY-friendly (and many certainly are), I’ve seen enough weekend warrior projects gone wrong to suggest professional installation, especially when your wall exceeds 3 feet in height. The peace of mind is worth every penny.

Essential Accessories

A successful block wall installation is about much more than just the blocks themselves. The supporting cast of materials makes all the difference between a wall that lasts decades and one that fails prematurely.

Behind every great wall is proper geogrid reinforcement—that synthetic mesh that extends into the soil behind the wall to create a reinforced mass. Equally important is the drainage pipe system, typically a 4-inch perforated pipe that collects and diverts water away from your wall’s foundation.

Never skip the filter fabric! This unsung hero prevents soil from migrating into your drainage materials and clogging the system. For securing those finishing cap blocks, SRW adhesive creates a permanent bond that withstands freeze-thaw cycles. And of course, ¾-inch clean crushed stone provides the essential drainage behind the wall that prevents hydrostatic pressure buildup.

For visual guidance that walks you through these components in action, check out these Step-By-Step Installation Videos – CornerStone®.

Installation Equipment

Whether you’re renting or purchasing, having the right tools makes all the difference in your block wall installation experience.

A quality plate compactor is non-negotiable for properly compacting both your base material and backfill. For precise grading and leveling, a laser level or transit ensures accuracy that the naked eye simply can’t match. I never start a wall without my trusty 4-foot mason’s level for checking block alignment.

A good rubber mallet allows for gentle adjustments without damaging the blocks, while a block splitter or diamond saw creates clean cuts for corners and curves. And your back will thank you for investing in a block dolly when moving those heavy materials around the job site.

Gravity Kits for DIYers

For homeowners in Bedford, Billerica, and Burlington looking to tackle smaller projects themselves, gravity wall kits offer an accessible entry point to block wall installation.

These systems typically work well for walls up to 4 feet tall and feature interlocking designs that eliminate the need for mortar—perfect for weekend warriors. Many systems easily form curved walls without complicated cutting, and some hollow-core systems gain additional strength when filled with ¾-inch stone.

These kits are perfect for garden borders, small retaining areas, and decorative landscape features. Most manufacturers include compatible cap stones and corner pieces for a polished, professional look.

For more inspiration on creating beautiful landscape retaining walls, visit our page on Landscape Retaining Wall.

Reinforced Systems for Tall Walls

When you need serious strength for taller applications throughout Woburn, Winchester, and surrounding areas, reinforced wall systems provide the necessary muscle to handle the load.

These systems typically feature hollow-core blocks that accept vertical rebar and grout for maximum structural integrity. They incorporate multiple geogrid layers extending into the soil at calculated intervals based on wall height and soil conditions.

Most walls over 4 feet tall require engineered design with professional stamped drawings to ensure safety and code compliance. Yes, these systems fall into a higher cost range, but there’s simply no substitute when dealing with significant soil retention needs, especially in our challenging New England climate where freeze-thaw cycles put extra stress on retaining walls.

Must-Have Installation Tools

Whether you’re evaluating a professional installation or considering a DIY approach, understanding the essential tools for proper block wall installation helps ensure quality results.

A plate compactor is the foundation of a solid wall, ensuring proper base and backfill compaction. Accurate grading and level blocks require a laser level and 4-foot mason’s level working in tandem. For making minor adjustments without damaging blocks, a rubber mallet is indispensable.

Creating clean cuts for custom fits around corners and curves demands either a block splitter or wet saw. Your body will thank you for using a back-saving dolly when moving heavy materials. And never forget proper safety gear—gloves, eye protection, dust mask, and appropriate footwear protect you throughout the project.

For larger projects in Lexington, Reading, and other communities we serve, we often bring in mini-excavators and skid steers to make site preparation more efficient and less backbreaking.

Frequently Asked Questions about Block Wall Installation

Let’s tackle some of the questions we hear most often when talking with homeowners in Woburn, Winchester, and throughout our service area. After installing countless block walls over the years, these are the things folks really want to know:

How high can I build without an engineer?

This is probably the most common question we get, and the answer depends on your local building codes. Generally speaking:

Most walls under 3 feet tall don’t require engineering plans in Massachusetts communities. These smaller projects are perfect for creating garden borders or managing minor grade changes in your yard.

Walls between 3-4 feet enter a gray area where requirements vary by town. Some Bedford or Burlington properties might need engineering at this height while others don’t.

Walls over 4 feet almost always require professional engineering documents. This isn’t just bureaucratic red tape – it’s genuinely about safety.

Even when engineering isn’t required, we always follow engineered best practices at AJM Grounds. A properly built 2-foot wall will last decades longer than a poorly built one, and we’re in this for the long haul with our clients!

Do I need a drain pipe behind every wall?

I can’t stress this enough – water is the #1 enemy of retaining walls. The question of drainage is absolutely crucial to the success of your block wall installation.

For very small walls (under 2 feet) in sandy, well-draining soils, you might get away with just proper gravel backfill. But I rarely recommend skipping drainage even then.

For walls over 2 feet tall, a perforated drain pipe is non-negotiable. Many parts of Reading and Stoneham have heavy clay soils that hold water, making proper drainage even more critical regardless of wall height.

For any wall over 4 feet or walls with geogrid reinforcement, comprehensive drainage systems are absolutely essential. When we install these larger walls, we’re extremely meticulous about getting the drainage right because we know it’s the difference between a wall that lasts for decades and one that fails prematurely.

Think of the drain pipe as cheap insurance for your investment. The cost of adding it during construction is minimal compared to the cost of repairing a failed wall later.

How do I estimate how many blocks I need?

Getting your material quantities right helps avoid costly mid-project runs to the supplier or wasted materials. Here’s my simple approach:

First, calculate your wall’s square footage by multiplying length × height. For a 20-foot long, 3-foot high wall, that’s 60 square feet.

Next, divide by the coverage of each block. Standard 8×8×16 blocks cover about 1.125 square feet each, so you’d need approximately 53 blocks (60 ÷ 1.125 = 53.3).

Always add at least 10% extra for cuts, waste, and potential future repairs. For our example, that brings us to 59 blocks.

Don’t forget to account for corners and ends! Each corner or end detail may require additional or special blocks depending on the system you’re using.

For complex projects in Winchester or Lexington with multiple corners, curves, or varying heights, our team can provide precise material estimates during a consultation. We’d rather help you get it right the first time than see you making multiple trips to the supplier.

For more detailed information on retaining wall construction methods, check out our page on Retaining Wall Construction.

Have more questions about your specific block wall installation project? We’re always happy to provide answers based on our years of experience serving the Greater Boston area!

Conclusion

Building a block wall installation is truly one of the smartest investments you can make for your property. Whether you’re looking to tame an unruly slope in Winchester, create a stunning garden feature in Lexington, or solve drainage issues in Woburn, a properly built block wall delivers decades of performance while enhancing your outdoor living space.

After helping hundreds of Massachusetts homeowners transform their properties, we’ve seen how these structures become beloved features that families enjoy for generations. The durability of concrete block means your investment will continue paying dividends long after wooden alternatives would have deteriorated.

While the DIY route might seem appealing for smaller projects, professional installation offers compelling advantages that often outweigh the initial cost savings:

Expert knowledge means your wall will be built right the first time, with proper consideration for New England’s unique soil conditions and freeze-thaw cycles. Our team understands the subtle nuances that make the difference between a wall that lasts decades and one that fails prematurely.

Efficiency and equipment allow our experienced crews to complete in days what might take a homeowner weeks of weekend work. We arrive with specialized tools and the manpower to handle heavy materials safely.

Structural integrity comes from following engineered best practices that ensure your wall will stand strong through harsh Massachusetts winters and summer downpours. We never cut corners on drainage – the number one factor in wall longevity.

Peace of mind through warranties and professional support means you’re not alone if questions arise years after installation. We stand behind our work with pride.

Permit handling takes the bureaucratic headache out of your hands. We’re familiar with local codes throughout Bedford, Billerica, Burlington and all the communities we serve, ensuring your project meets all requirements.

At AJM Grounds, we believe in creating outdoor spaces that blend beauty with function. Our approach to block wall installation focuses on the details that matter – from perfectly level base courses to proper drainage systems that protect your investment for decades to come.

Whether you’re considering a modest garden wall or a major slope-stabilizing structure, we’d love to help bring your vision to life. Schedule a consultation, and we’ll walk your property together, listen to your goals, and craft a solution custom to your specific needs and budget.

For more information about our approach to creating lasting landscape solutions, visit our page on Retaining Wall Construction.

Average costs based on publicly available internet data; actual pricing varies widely by project scope, material choice, and location. Contact AJM Grounds for a personalized quote for your specific project needs.